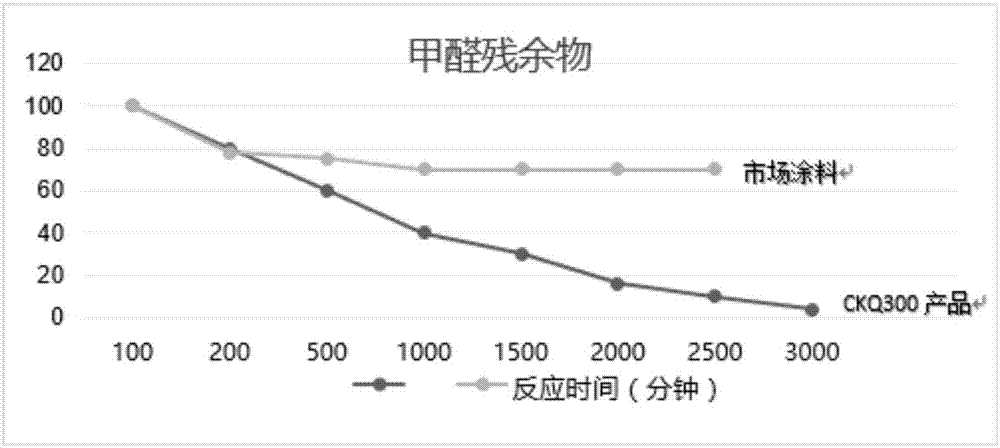

Anti-formaldehyde mineral paint and preparation method

An anti-formaldehyde and mineral technology, applied in coatings and other directions, can solve the problems of inability to effectively decompose formaldehyde and incomplete removal of formaldehyde.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] The invention provides anti-formaldehyde mineral paint, its component and preparation method are as follows:

[0118] Step 1, take 180 parts of water, 1.5 parts of cellulose, 1.5 parts of bentonite, 1.5 parts of multifunctional amine additives, 4 parts of dispersants, 0.5 parts of wetting agents, 1 part of preservatives, 0.5 parts of The antifoaming agent of 8 parts, the propylene glycol of 8 parts, feeds and mixes successively, obtains mixture 1;

[0119] Step 2, take 200 parts of titanium dioxide, 40 parts of heavy calcium, and 15 parts of diatomaceous earth, and put them into mixture 1 in turn to obtain mixture 2;

[0120] Step 3, take 200 parts of emulsion, 50 parts of hollow microsphere polymer emulsion, 0.5 part of defoamer, 1 part of leveling agent, 0.5 part of RM-8W thickener, 0.5 part of PX-026 thickener The thickener and 30 parts of water are put into the mixture 2 in turn to obtain the anti-formaldehyde mineral paint.

[0121] Step 4, filtering the formalde...

Embodiment 2

[0123] The invention provides anti-formaldehyde mineral paint, its component and preparation method are as follows:

[0124] Step 1, take 200 parts of water, 2 parts of cellulose, 2 parts of bentonite, 2 parts of multifunctional amine additives, 5 parts of dispersant, 1 part of wetting agent, 2 parts of preservative, 1 part of The antifoaming agent of 8-25 parts of propylene glycol, feeds and mixes successively, obtains mixture 1;

[0125] Step 2, take 220 parts of titanium dioxide, 60 parts of heavy calcium, and 20 parts of diatomaceous earth, and put them into mixture 1 in turn to obtain mixture 2;

[0126] Step 3, get 300 parts of emulsion, 80 parts of hollow microsphere polymer emulsion, 1 part of defoamer, 2 parts of leveling agent, 1 part of RM-8W thickener, 1 part of PX-026 thickener Thickener and 50 parts of water are dropped into the mixture 2 successively to obtain formaldehyde-resistant mineral paint.

[0127] Step 4, filtering the formaldehyde-resistant mineral p...

Embodiment 3

[0129] The invention provides anti-formaldehyde mineral paint, its component and preparation method are as follows:

[0130] Step 1, take 220 parts of water, 4 parts of cellulose, 4 parts of bentonite, 4 parts of multifunctional amine additives, 7 parts of dispersant, 2 parts of wetting agent, 3 parts of preservative, 3 parts of The antifoaming agent of 25 parts, the propylene glycol of 25 parts, feed and mix successively, obtain mixture 1;

[0131] Step 2, take 280 parts of titanium dioxide, 120 parts of heavy calcium, and 30 parts of diatomaceous earth, and put them into mixture 1 in turn to obtain mixture 2;

[0132] Step 3, take 400 parts of emulsion, 120 parts of hollow microsphere polymer emulsion, 3 parts of defoamer, 3 parts of leveling agent, 3 parts of RM-8W thickener, 3 parts of PX-026 thickener Thickener and 80 parts of water are dropped into the mixture 2 successively to obtain formaldehyde-resistant mineral paint.

[0133] Step 4, filtering the formaldehyde-res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com