Injection molding mould for long-edge skew stud long curved sheet product

A stud and oblique technology, which is applied in the field of injection molds for long-side oblique studs and long curved products, can solve the problems of high production cost, low cutting amount and feed speed, high operating cost, etc., and achieve the goal of mold material Reduce costs, reduce defective products and waste products, and avoid the effects of large horse-drawn carts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

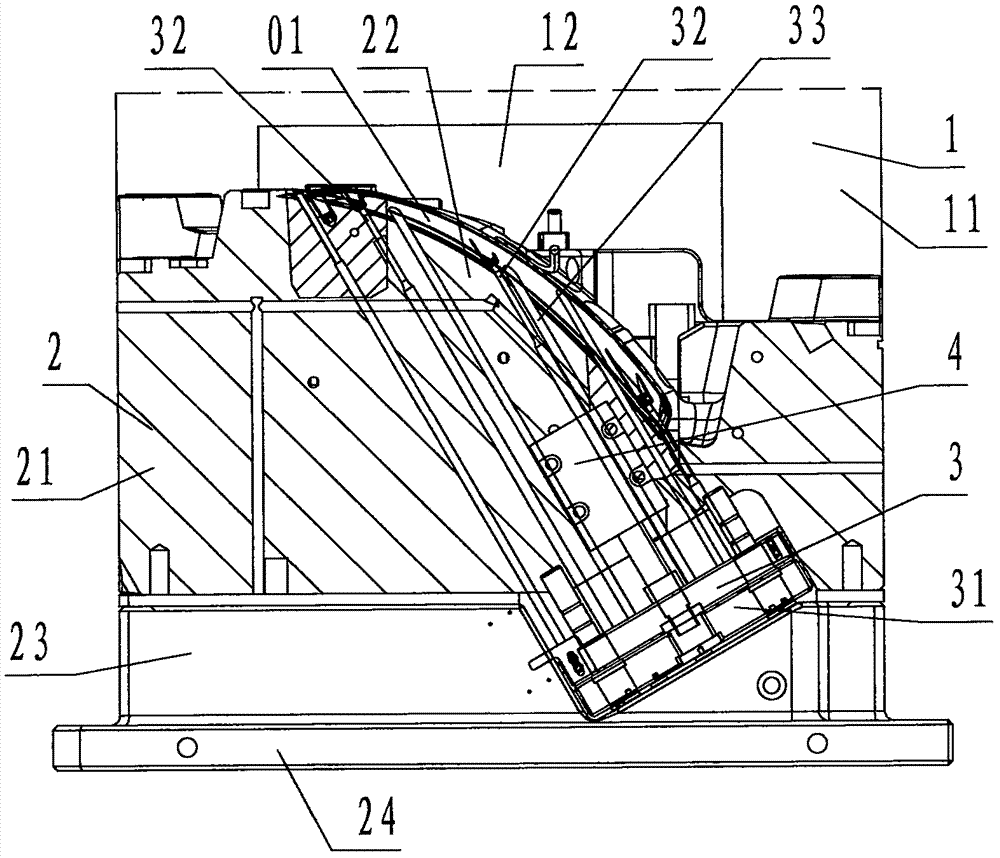

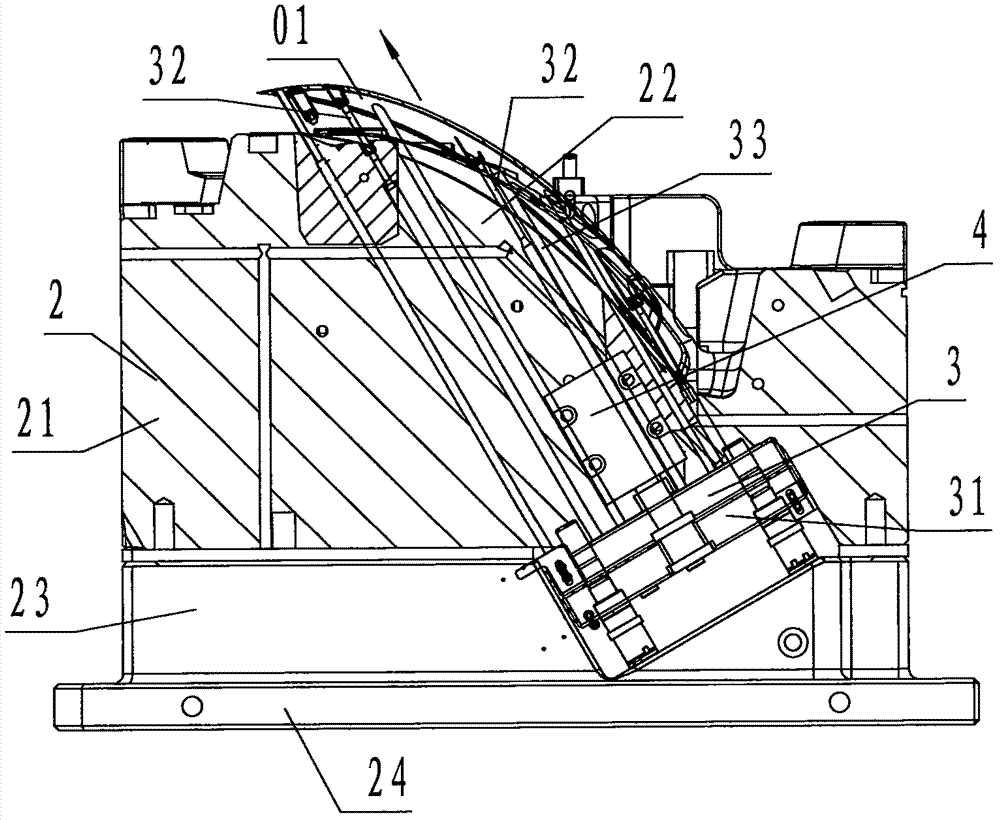

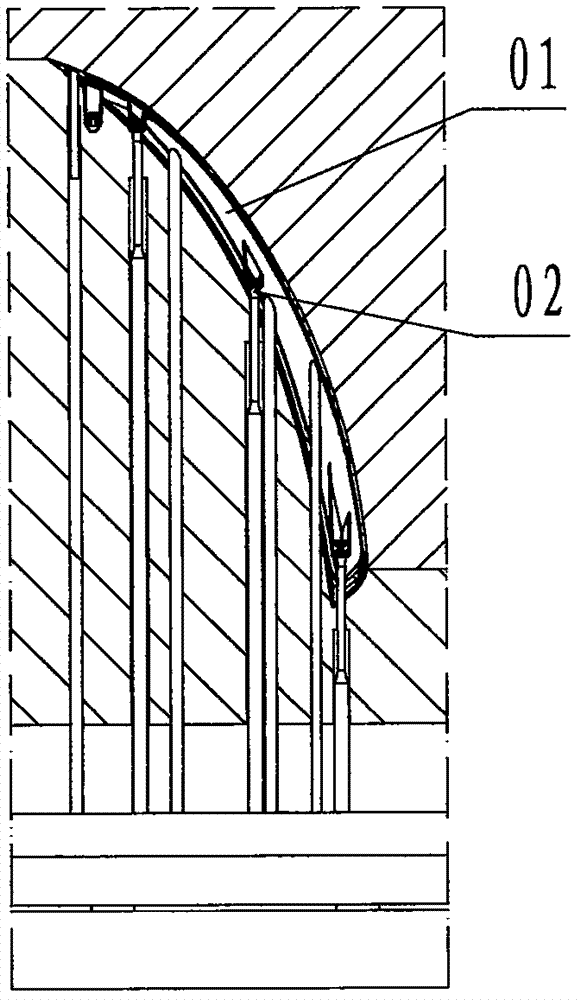

[0033] refer to Figure 1 ~ Figure 2 , a kind of injection mold of long-side oblique stud long curved piece product of the present invention, comprises fixed mold 1, movable mold 2, ejection mechanism 3, oil cylinder 4, wherein: described movable mold 2 is provided with movable mold loading Plate 21, core 22, die foot 23 and base plate 24; the core 22 is a steel block member with the back shape of the long curved stud product 01 formed on the right side, and the core 22 It is fixedly connected to the top of the movable mold carrier plate 21 by tilting downward from left to right;

[0034] The fixed mold 1 is provided with a panel, a fixed mold carrier plate 11 and a cavity 12; the cavity 12 is a steel block-shaped component with the external shape of the formed long-side oblique stud long curved sheet product 01 below , corresponding to the core 22, the cavity 12 is fixedly connected to the bottom of the fixed mold support plate 11 from left to right and tilts downward;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com