Air-cooled horizontal refrigerator

A cold horizontal and freezer technology, applied in coolers, household refrigeration devices, cooling fluid circulation devices, etc., can solve the problems of easy frosting in the air duct, extended air supply distance, and high top temperature, so as to improve space utilization, The effect of simplifying installation steps and reducing space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

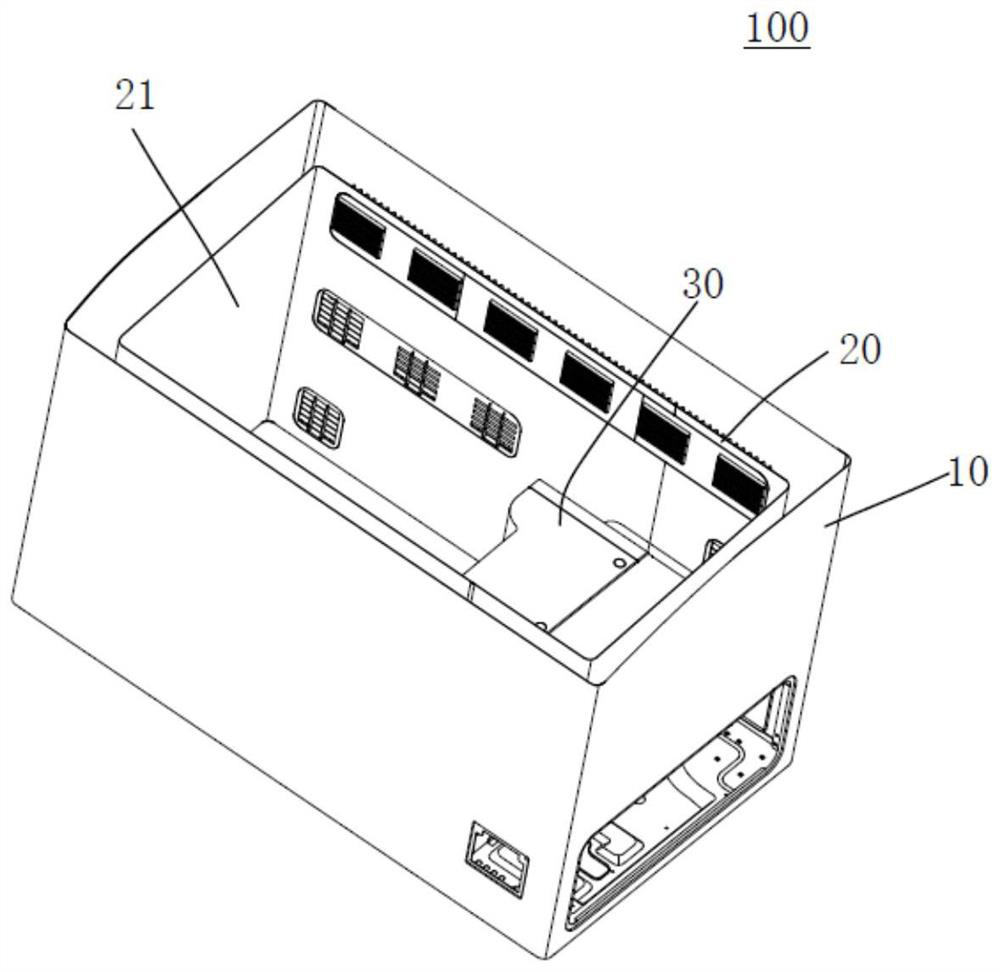

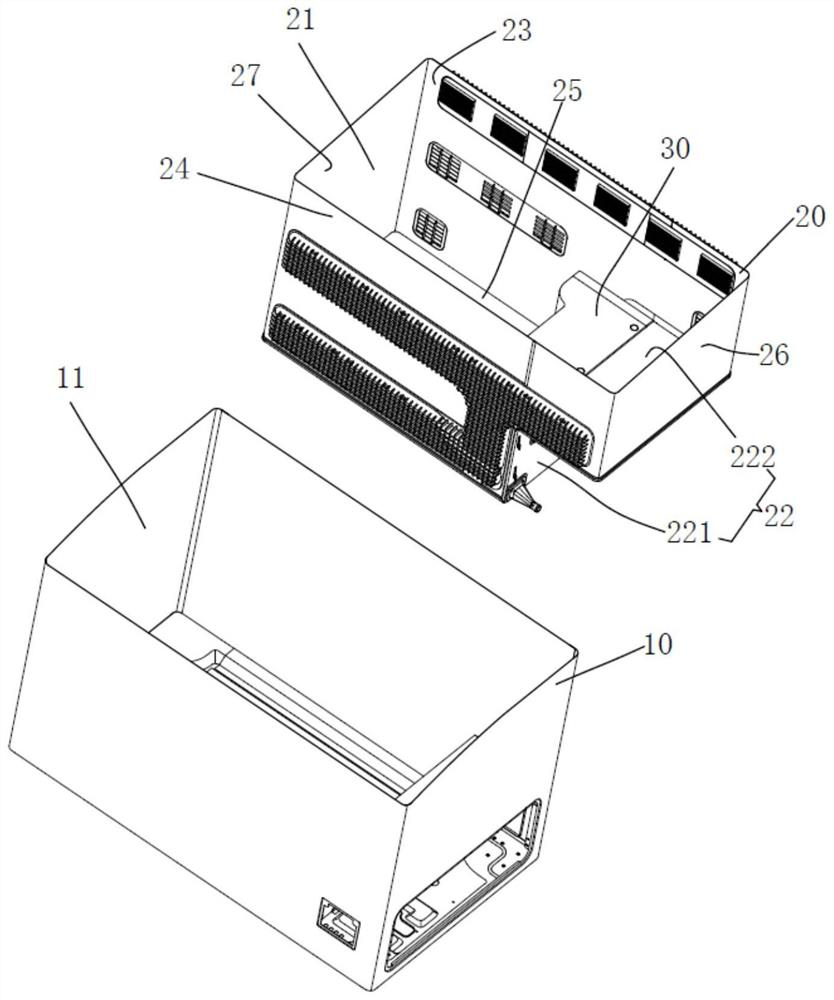

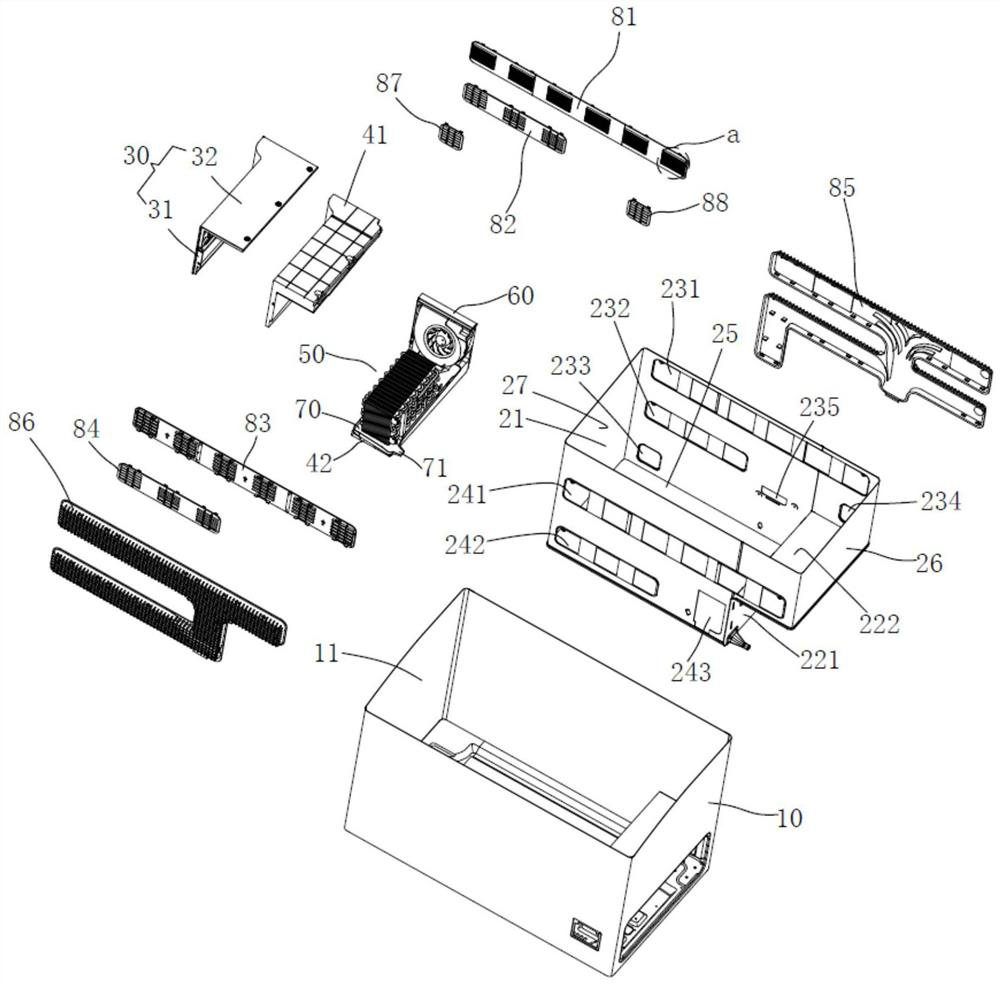

[0034] figure 1 It is a partial structural schematic diagram of the horizontal refrigerator in the first embodiment of the present invention; figure 2 for figure 1 Schematic diagram of the decomposed liner and box shell of the mid-horizontal freezer; Figure 3A for figure 1 Schematic diagram of the decomposition of the horizontal freezer; Figure 3B for Figure 3A The enlarged schematic diagram of the area a in ; Figure 4A to Figure 4C for figure 1 Schematic cross-section of a mid-horizontal freezer at different angles of view.

[0035] Such as Figures 1 to 4C As shown, the first embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com