Preparation method of graphene/manganese dioxide composite electrode materials for supercapacitor

A technology of supercapacitor and manganese dioxide, which is applied in the field of nanomaterials, can solve the problems that electrons and ions cannot diffuse rapidly, the depth of bulk phase diffusion and penetration is limited, the size, shape, crystal form are difficult, etc., and reach a good market Application prospect, simple preparation method, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

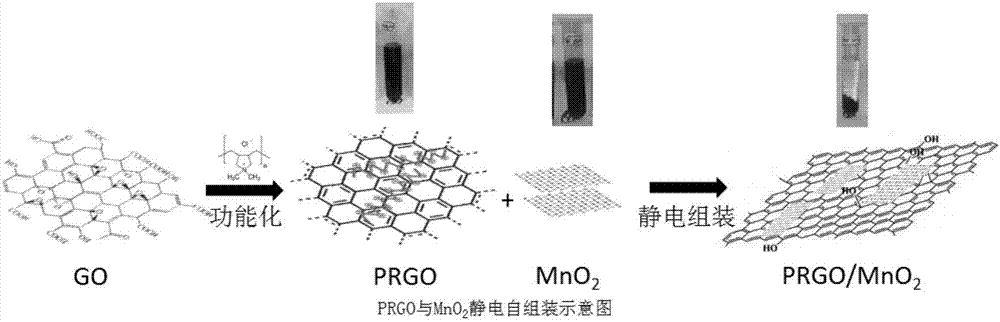

[0026] The invention provides a kind of preparation method of graphene / manganese dioxide composite electrode material for supercapacitor, comprises the following steps:

[0027] A) mixing and preheating sodium lauryl sulfate solution, sulfuric acid solution and water to obtain a mixed solution;

[0028] B) mixing and heating the mixed solution and potassium permanganate solution to obtain manganese dioxide nanosheets;

[0029] C) mixing and stirring the manganese dioxide nanosheets and the functionalized modified graphene nanosheets in water, and then centrifuging and freeze-drying to obtain a graphene / manganese dioxide composite electrode material for supercapacitors.

[0030] The present invention firstly prepares manganese dioxide nanosheets, and the specific method is:

[0031] A) mixing and preheating sodium lauryl sulfate solution, sulfuric acid solution and water to obtain a mixed solution;

[0032] B) mixing and heating the mixed solution and potassium permanganate s...

Embodiment 1

[0058] At a power of 250W and a frequency of 25kHz, ultrasonication was performed for 120min to obtain 100mL of a graphene oxide dispersion with a concentration of 0.5g / L, and 2mL of polydiallyl with a weight average molecular weight of 100000-200000 at a concentration of 0.6‰ was added to it. Dimethyl ammonium chloride modifier solution, 1.2mL hydrazine hydrate reducing agent with a mass fraction of 3%, and ammonia water was added to adjust the pH of the reaction system to PH=10. Heat the reaction in a water bath at 90°C for 3 hours to obtain a functionalized modified graphene dispersion. The resulting dispersion is centrifuged to separate the product, and after freeze-drying and drying, the functionalized modified graphene (PRGO for short) is obtained. ).

[0059] Take 283.2ml of ultrapure water in a 500°C flask, add 32ml 0.1mol / L sodium dodecyl sulfate solution (SDS) and 1ml 0.1mol / L H 2 SO 4 solution, mix well and preheat at 95°C for 15min, then measure 3.2ml of 0.05mol / ...

Embodiment 2

[0070] At a power of 250W and a frequency of 25kHz, ultrasonication was performed for 120min to obtain 100mL of a graphene oxide dispersion with a concentration of 0.5g / L, and 2mL of polydiallyl with a weight average molecular weight of 200,000-300,000 at a concentration of 0.08‰ was added to it. Dimethylammonium chloride modifier solution, 1.2mL sodium borohydride solution with a mass fraction of 4%, and ammonia water were added to adjust the pH of the reaction system to pH=10. Heating and reacting in a water bath under normal pressure at 90° C. for 2 hours to obtain a dispersion of functionalized modified graphene. The dispersion obtained from the reaction was centrifuged to separate the product, and after freeze-drying and drying, the functionalized modified graphene was obtained.

[0071] Take 283.2ml of ultrapure water in a 500°C flask, add 32ml 0.1mol / L sodium dodecyl sulfate solution (SDS) and 1ml 0.1mol / L H 2 SO 4 solution, mix well and preheat at 95°C for 15min, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com