Micropore pressure hood for treating scars based on 3D printing and manufacturing method

A technology of 3D printing and pressure cover, which is applied in medical science, dressing, surgery, etc., can solve the problems of poor pressure treatment effect, inability to greatly modify, complicated production procedures, etc., and achieve rapid manufacturing, weight reduction, and lower manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

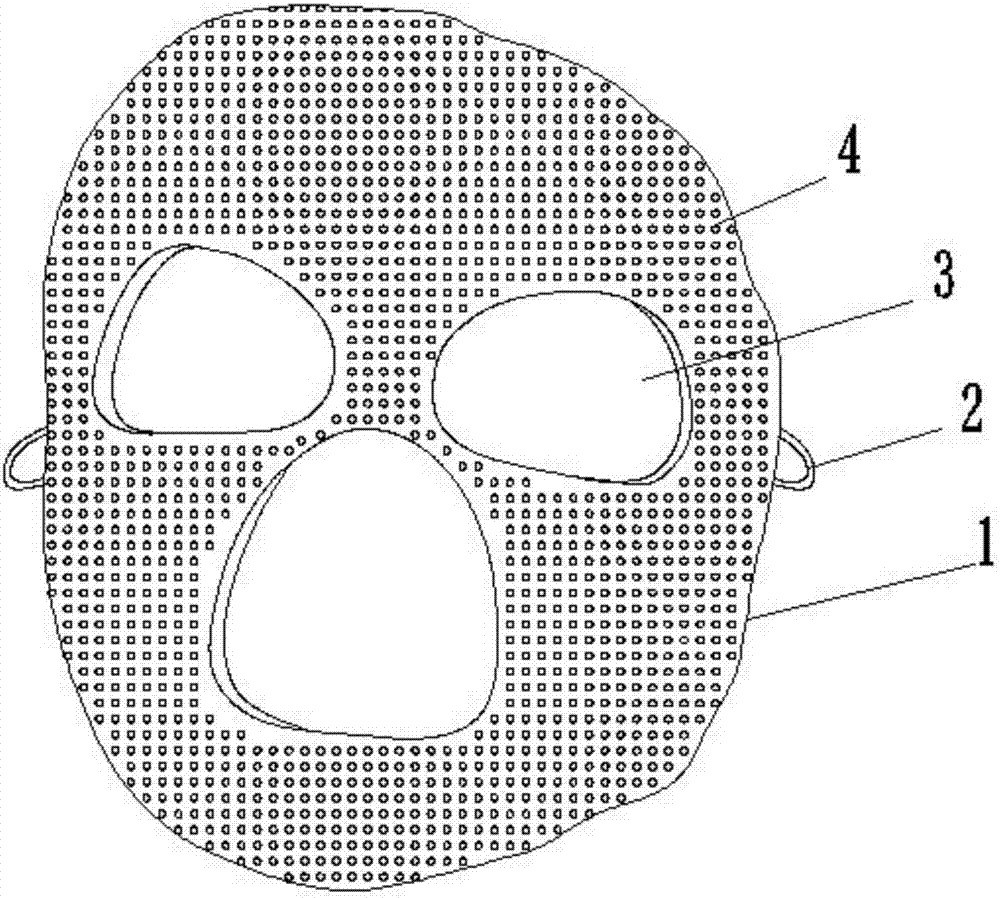

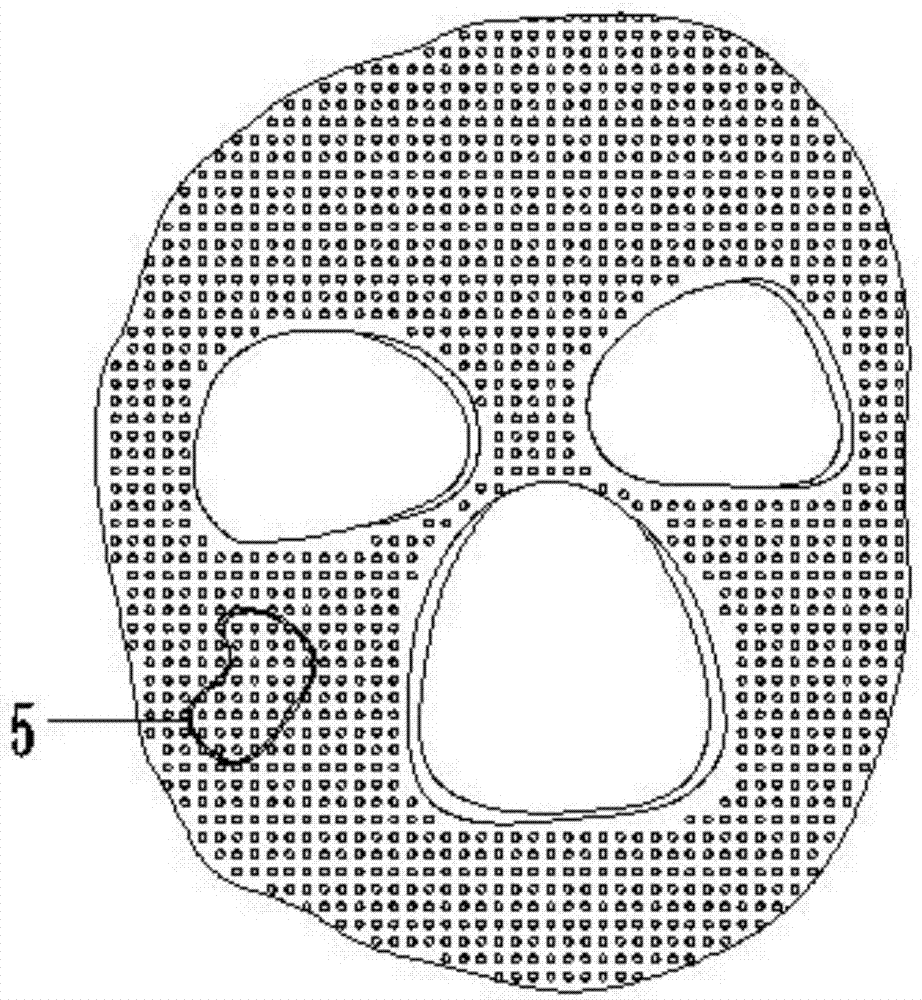

[0032] This embodiment takes the pressure mask worn on the patient's face as an example to describe the present invention in detail. The structure of the microporous pressure mask includes a pressure mask main body 1 and a fastening belt 2 that can fit the patient's face. The pressure mask main body 1 is printed by 3D. The main body of the pressure mask is provided with a plurality of evenly distributed micropores 3 at least at the position opposite to the scar part of the human body.

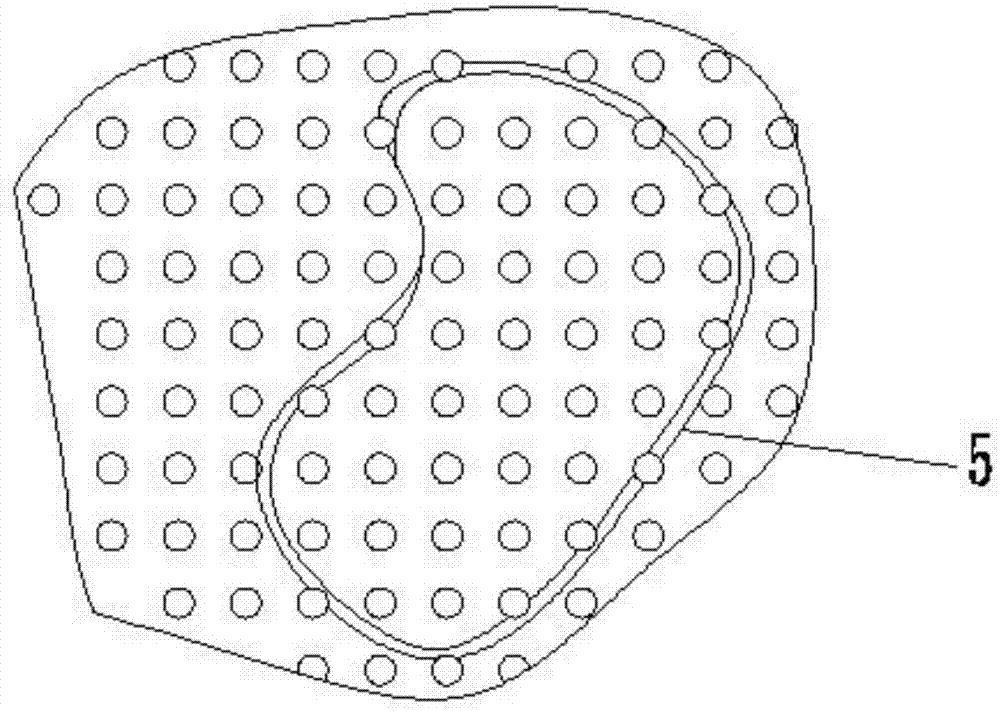

[0033] In this embodiment, the aperture of the micropore is less than 0.5mm, and the pressure cover is provided with a depression at the position in contact with the scar of the human body, the depth of the depression is less than (or equal to) the thickness of the corresponding scar, and the main body of the pressure cover is provided with One or more avoidance holes 3 that can expose the non-scar parts of the human body, and at the same time, the position on the main body of the pressure mask ...

Embodiment 2

[0042] The first embodiment above is described by taking the mask used on the patient's face as an example, but the pressure mask of the present invention can also be used on other parts of the human body suffering from scars, such as the chest, abdomen, waist or buttocks of the human body. When used in other positions, the pressure cover must at least have fastening straps and evenly distributed micro-holes, and avoidance holes and weight-reducing holes (can be used as air holes) can be set up according to actual needs, such as Figure 4 Shown is a pressure mask for the scarred part of the waist of the human body, with weight-reducing holes 6 thereon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com