Rapid type pipeline connector

A connector and shortcut technology, applied in the direction of couplings, mechanical equipment, etc., can solve the problems of unfavorable pipe fitting assembly, one or more quick-connect pipe fitting modular connection pipe connectors, and complicated processing methods, etc., to achieve Simplified processing, simple and direct connection method, and easy guarantee of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

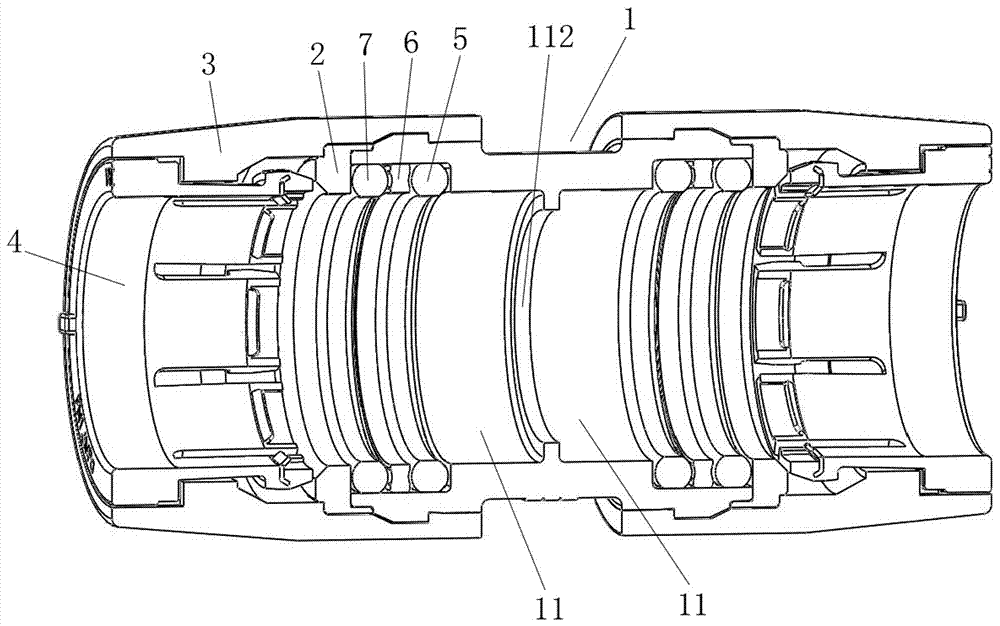

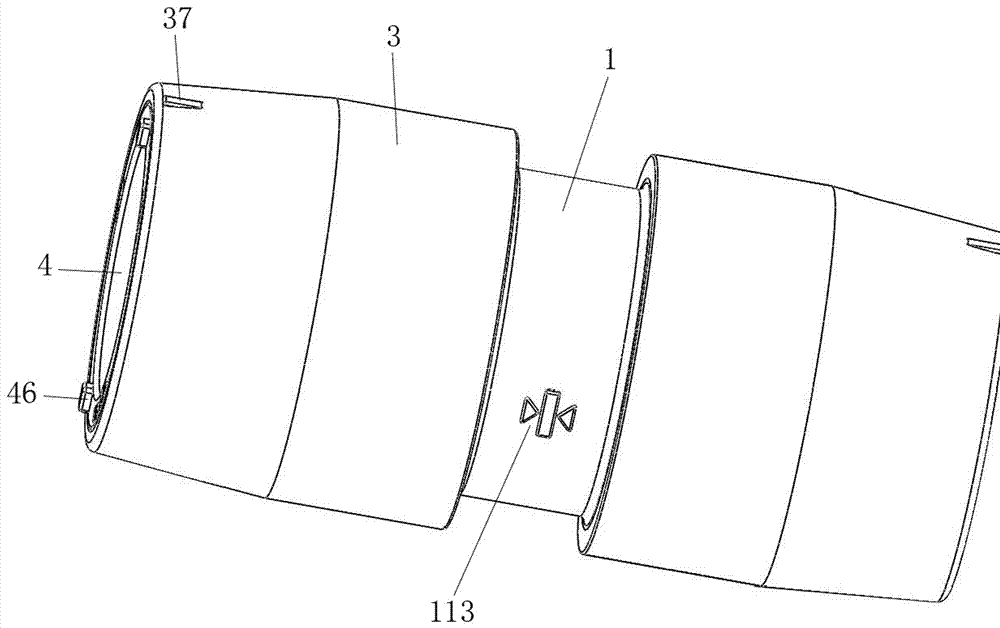

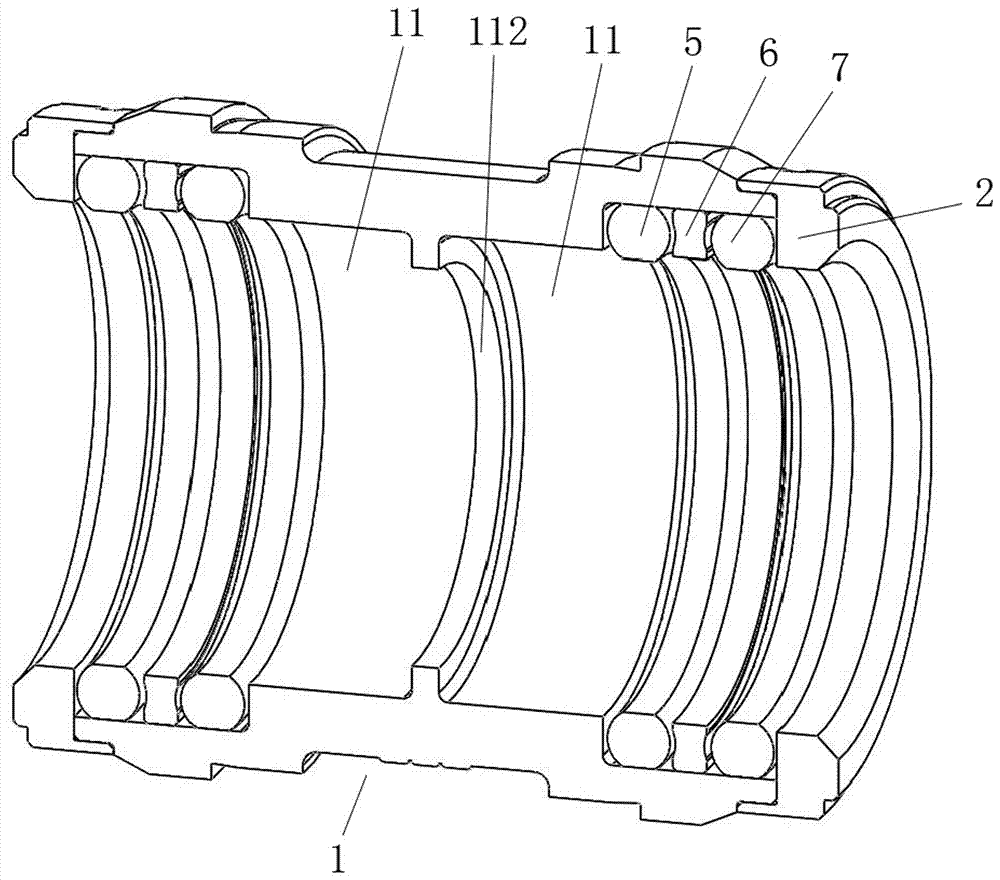

[0045] like Figure 1a , 4b As shown, the quick pipe connector proposed by the present invention includes: a pipe connector, which includes at least one connector housing 1 , and is provided with at least two connection ports 11 for externally connecting the pipe 100 . When the pipeline connector only includes one connector housing 1, only the connection port 11 is provided on the connector housing 1. When the pipeline connector is assembled and connected by at least two connector housings 1, not only A connection port 11 is provided, and an adapter port 12 for assembly connection is also provided.

[0046] In the first embodiment, the pipe connector only includes one connector housing 1 , and the connector housing 1 is provided with two connection ports 11 .

[0047] About connection ports:

[0048] like Figure 1a to Figure 1f As shown, the inner wall of each connection port 11 is provided with a ring of connection grooves 111, the connection grooves 111 are connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com