Emergency oil supply system for steam turbine generator set

A technology for generating sets and oil supply systems, which is applied in the field of lubricating oil systems, and can solve the problems that AC lubricating oil pumps and DC lubricating oil pumps cannot be started, are difficult to implement, and economic losses of power generation companies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

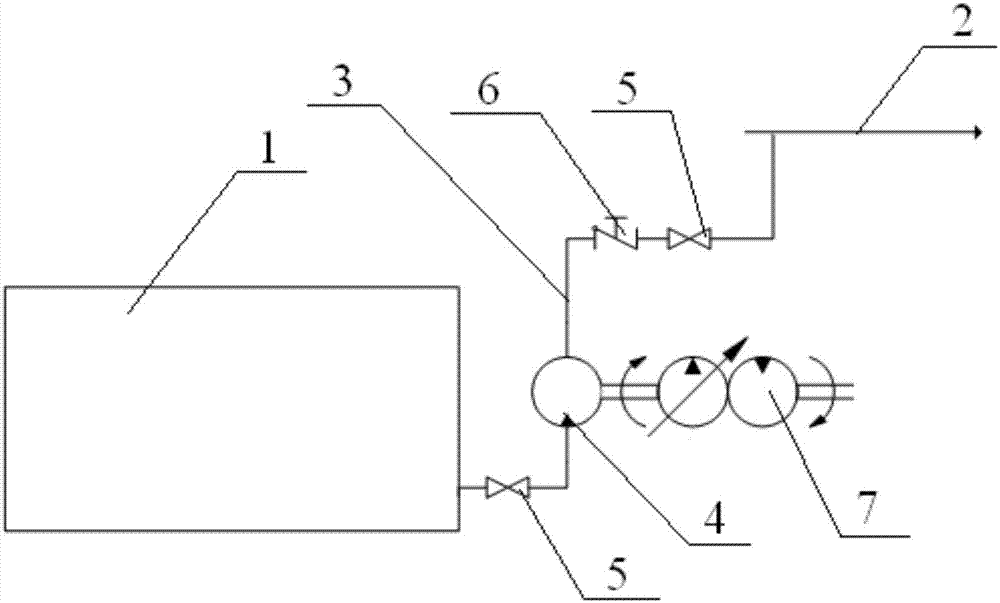

[0017] An emergency oil supply system for a steam turbine generating set, the structure of which is as follows figure 1 As shown, it includes a centrifugal pump 4, a diesel engine 7, a check valve 6, an oil pipeline 3 and two manual valves 5, the oil pipeline 3 is used to connect the main oil tank 1 and the lubricating oil main pipe 2, and the centrifugal pump 4 is arranged on the oil pipeline 3 Among them, the drive shaft of the centrifugal pump is connected to the output shaft of the diesel engine, and the diesel engine drives the centrifugal pump to work; the check valve 6 is arranged in the oil pipeline between the centrifugal pump 4 and the lubricating oil main pipe 2 to prevent the lubricating oil from flowing backward; two manual The valves are respectively arranged in the oil pipelines at both ends of the centrifugal pump 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com