Impact device for tooth frame abrasion resistance sealing protective sleeves of mining machine

A technology of sealing sheath and impact device, which is used in cutting machinery, earth-moving drilling, slitting machinery, etc., can solve the problems of easy damage to directly contacted materials, lubrication and cooling of power system, and difficulty in replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

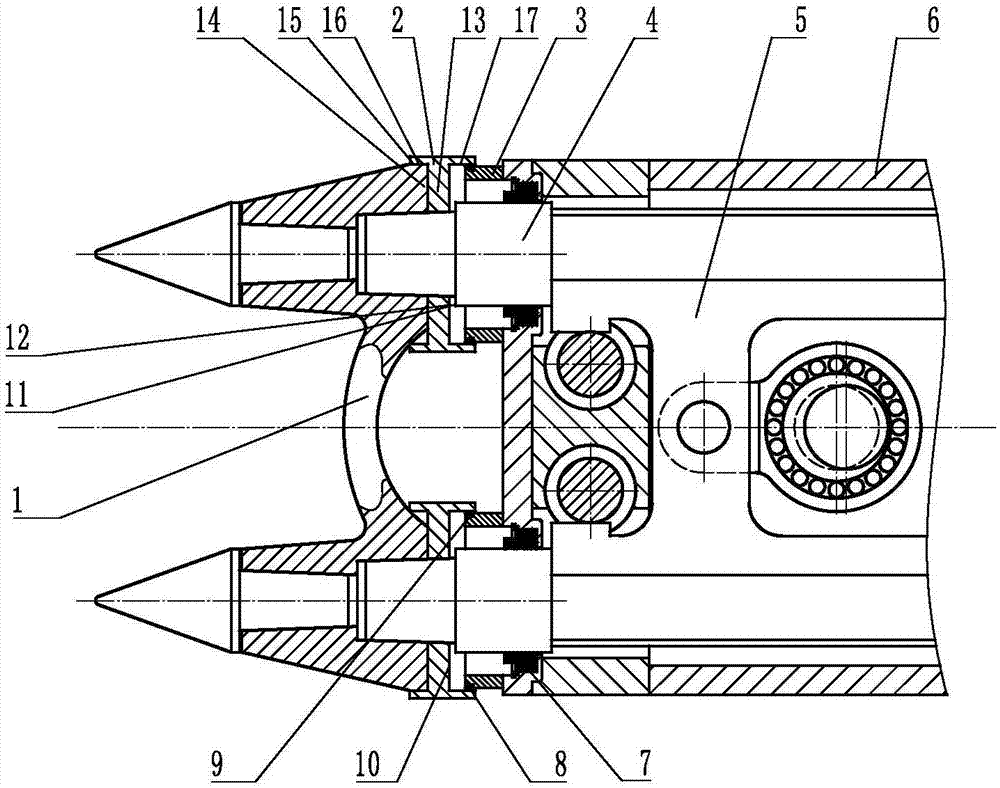

[0052] Such as figure 1 The impact device shown in the excavator gear frame wear-resistant sealing sheath 2 includes punching gear frame 1, box guard guide rod cover 3, gear frame wear-resistant sealing sheath 2, impact guide frame 5 and power box body 6, etc., and the impact guide The frame 5 is arranged in the power box body 6, and the box seal 7 etc. are arranged between the impact guide frame 5 and the power box body 6, and the box guard guide rod cover 3 is fixedly connected with the power box body 6, and the impact guide frame 5 includes The impact guide rod 4, etc., the end of the impact guide rod 4 is set at the box protection guide rod cover 3 outside the power box 6, the gear rack wear-resistant sealing sheath 2, etc. are arranged at the rear of the punch rack 1, and the punch rack 1. The rear part is connected with the impact guide rod 4. The wear-resistant sealing sheath 2 of the gear frame is arranged outside the cover 3 of the box body protection guide rod. The ...

Embodiment 2

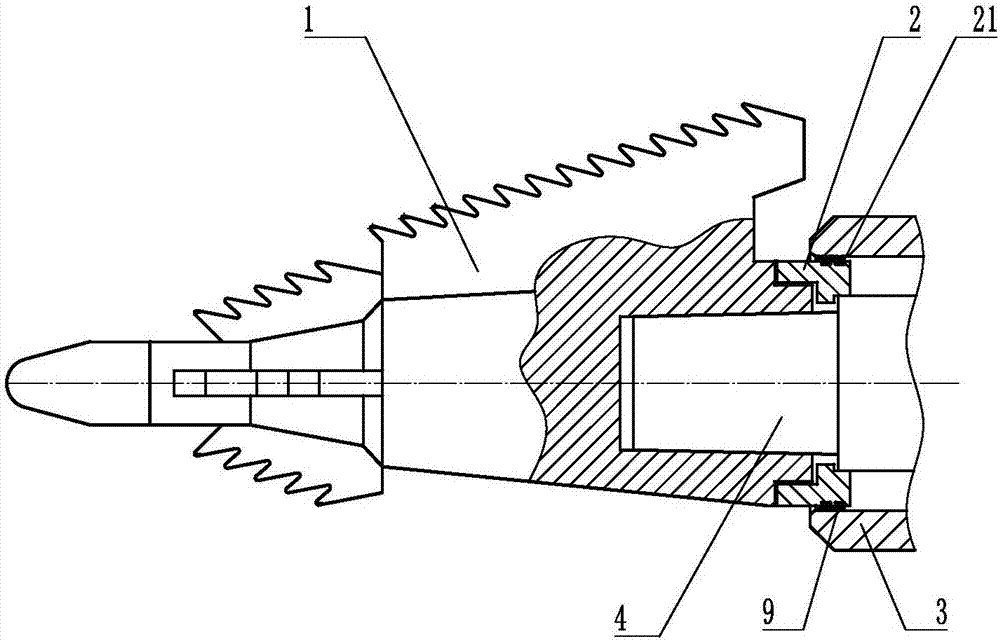

[0060] Such as figure 2 , image 3 Shown is an impact device of a gear frame wear-resistant sealing sheath 2 for a mining machine. Gear frame sheath seals 9 are provided between the rod covers 3, and when the gear frame wear-resistant sealing sheath 2 is arranged inside the box guard guide rod cover 3, a gear frame wear-resistant sealing sheath 2 is provided outside The wear-resistant sealing surface 18 of the sleeve, and the wear-resistant sealing surface 18 of the sheath cooperates with the gear frame sheath seal 9 for sealing.

[0061] The gear rack sheath seal groove 21 can also be set on the gear rack wear-resistant sealing sheath 2, the gear rack sheath seal 9 is arranged on the gear rack sheath seal groove 21, and the gear rack sheath seal 9 is connected with the box body The inner cavity of the protective guide rod cover 3 is sealed, and the rack sheath seal 9 prevents material dust from entering the casing protective guide rod cover 3 and prevents the material from...

Embodiment 3

[0066] Such as Figure 4 , Figure 5 Shown is a mining machine tooth frame wear-resistant sealing sheath 2 impact device, the tooth frame sealing sleeve block 13 includes the fixed tooth frame sealing sleeve block inner circular surface 23, etc., and the impact guide rod 4 is provided with fixed teeth correspondingly. The outer circular surface 24 of the frame sealing sleeve stopper, the inner circular surface 23 of the fixed gear frame sealing sleeve stopper and the outer circular surface 24 of the fixed gear frame sealing sleeve stopper block cooperate to prevent the wear-resistant sealing sheath 2 of the gear frame from impacting the axial direction of the guide rod 4 Shake from side to side.

[0067] It is also possible to cooperate with the inner circular surface 23 of the fixed gear frame sealing sleeve block and the outer circular surface 24 of the fixed gear frame sealing sleeve block, and the sealing sleeve cooperates with the end face 16 of the gear frame and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com