Rapid demolishing device and method for pile head of filling pile

A technology of cast-in-situ piles and pile heads, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering. It can solve the problems of damage to the quality of engineering piles, low construction efficiency, and large noise pollution, so as to shorten the required time and improve construction efficiency. , Guarantee the effect of pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

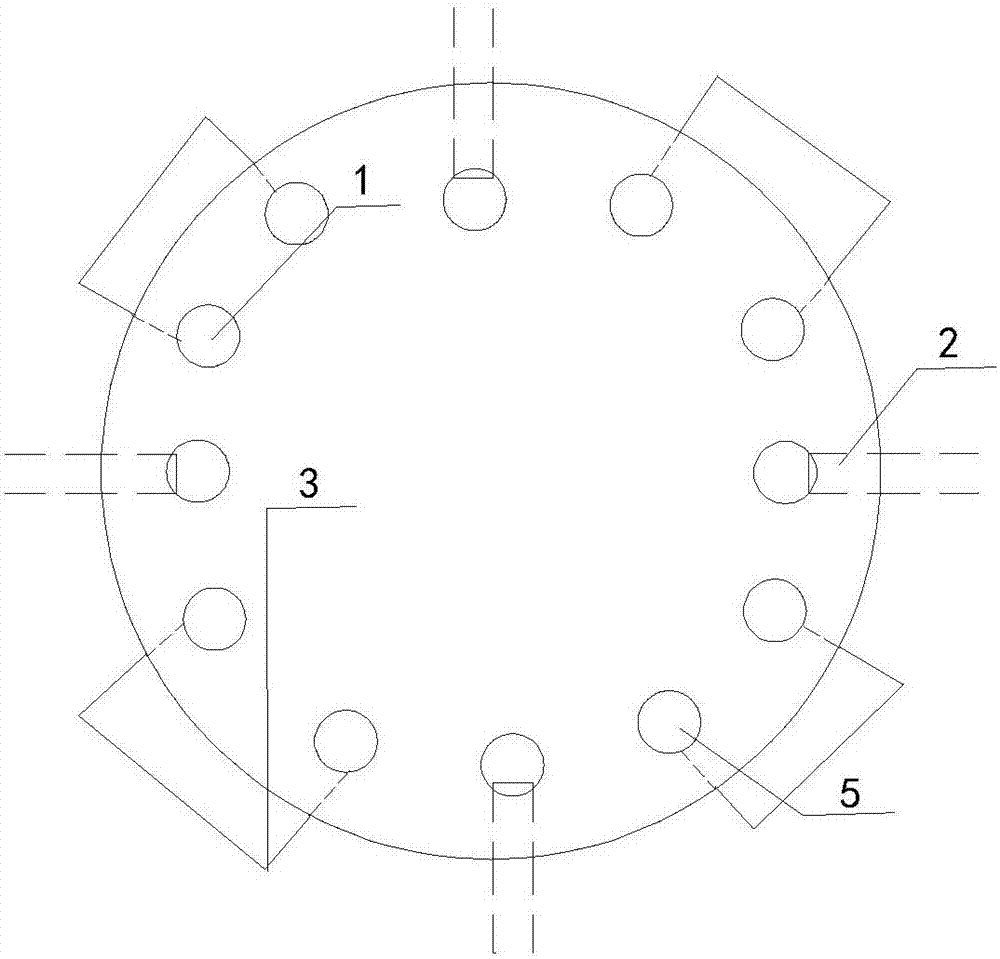

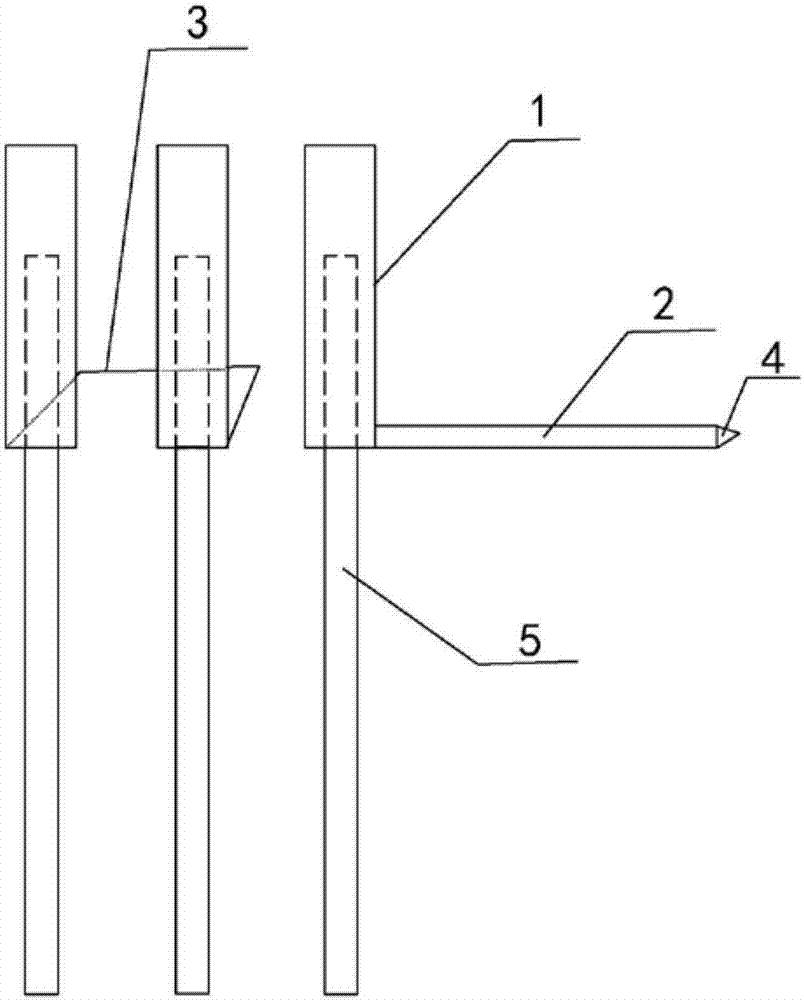

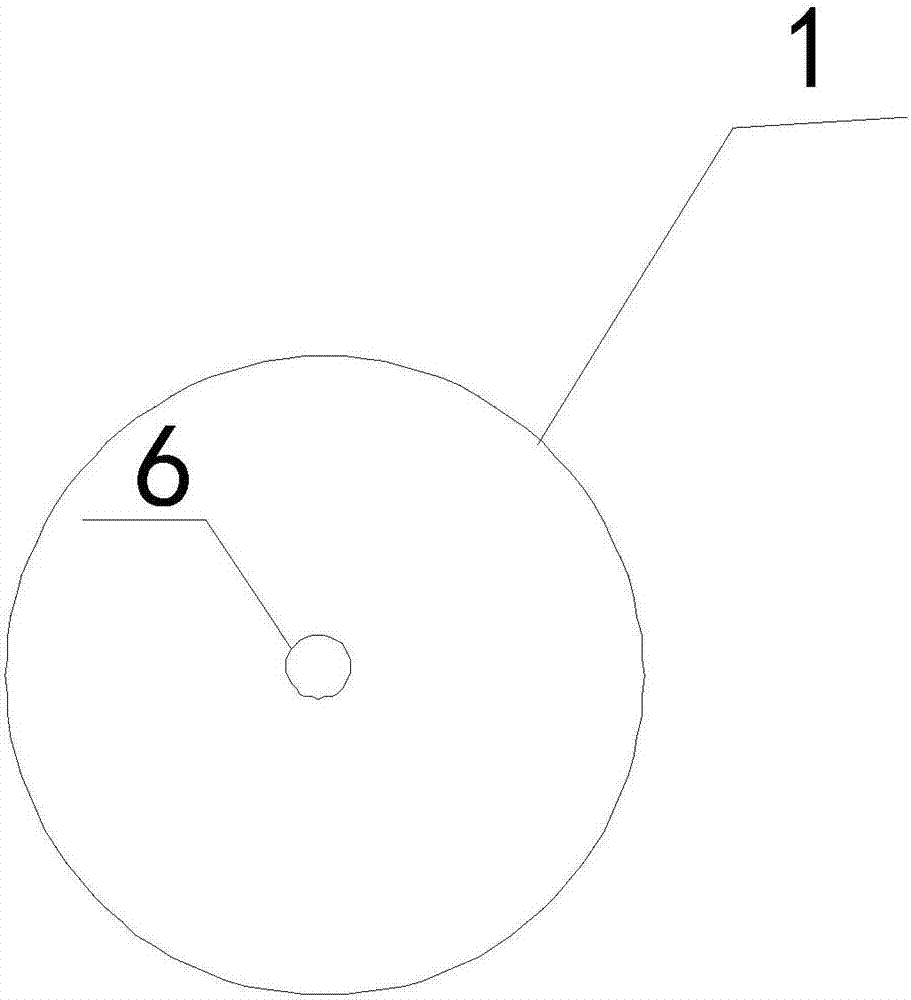

[0025] see Figure 1-Figure 4 According to the present invention, the quick removal device for cast-in-situ pile head includes a prefabricated steel cage, an isolation sleeve 1 , an isolation collar 3 and an expansion catheter 2 .

[0026] Specifically, the prefabricated reinforcement cage includes a plurality of reinforcement bars 5 arranged vertically around, and the upper part of the reinforcement bars 5 is the portion of the reinforcement bars above the design level. The lower end of the spacer sleeve 1 is provided with a shaft hole 6 from bottom to top, and the shaft hole 6 is a blind hole, which does not go through the top of the spacer sleeve 1 . The shaft hole 6 is matched and connected with the steel bar 5, so that the spacer sleeve 1 is sheathed with the steel bar part above the design level. The two ends of the spacer collar 3 are respectively connected to the spacer sleeve 1, and an annular belt is formed between the two ends of the spacer collar 3, and the annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com