Pre-embedding construction method for embedding top plate of cover-excavation top-down structure into underground diaphragm wall

A construction method, cover-excavation technology, applied to foundation structure engineering, sheet pile walls, underwater structures, etc., to achieve the effects of controllable construction period, avoiding chiseling and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

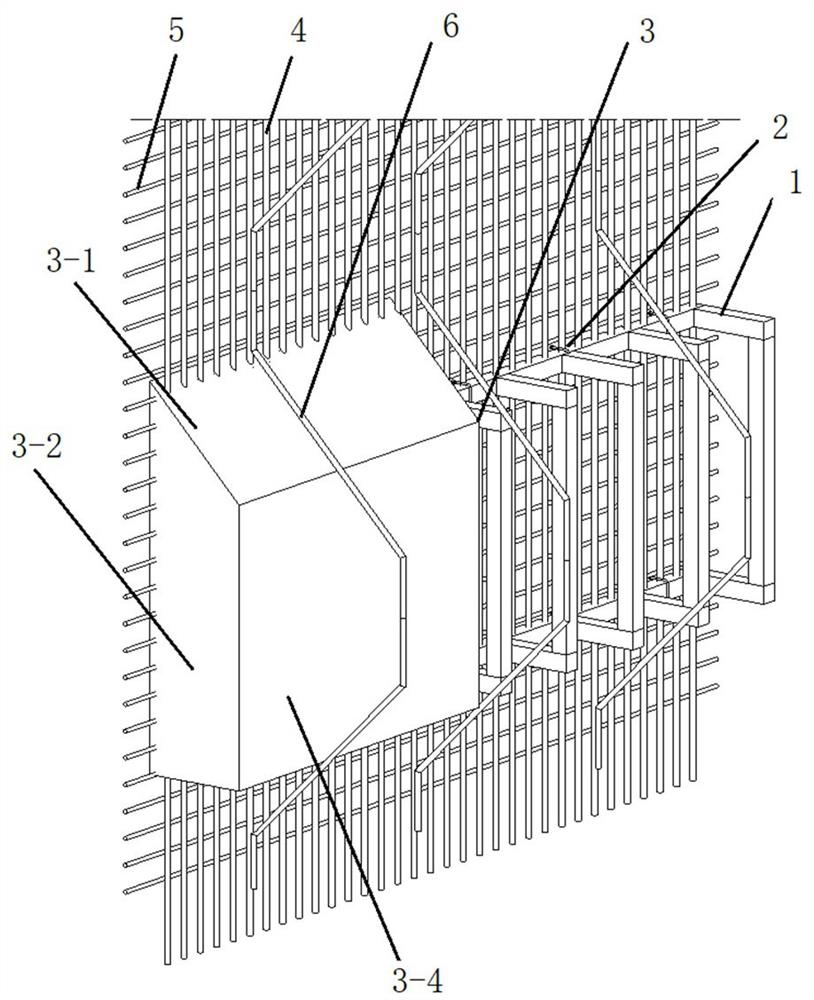

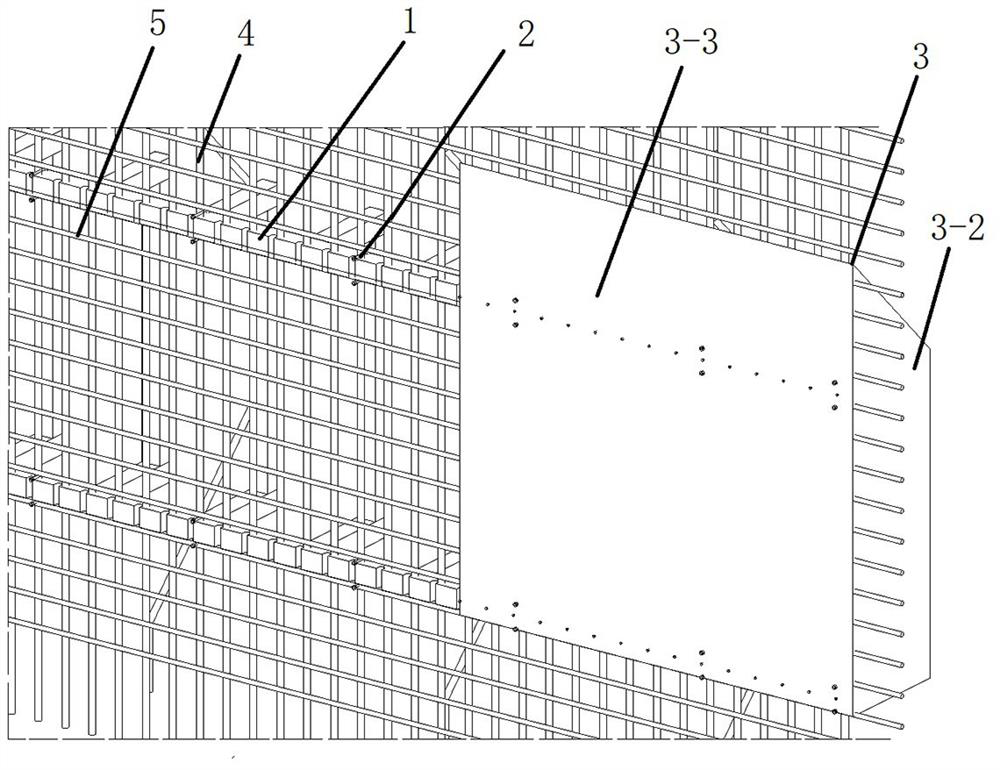

[0024] Example: such as Figure 1-5 As shown, this embodiment relates to a pre-embedded construction method in which the top plate of the cover-excavation structure is embedded in the ground connection wall, and the steps of the pre-embedded construction method are as follows:

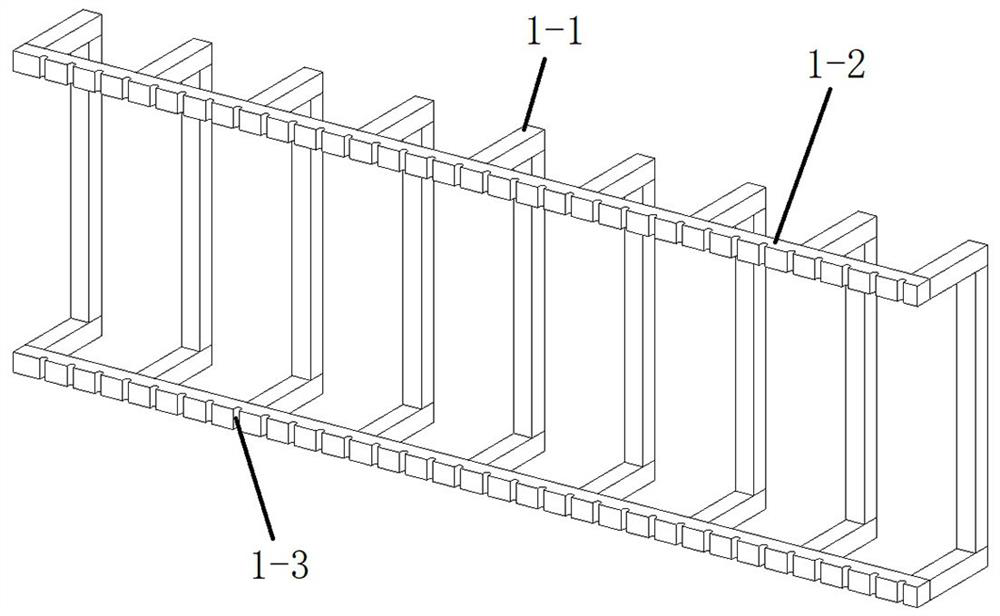

[0025] a. If figure 1 , figure 2 and Figure 5 As shown, according to the design elevation of the top and bottom of the embedded position 9 of the roof structure 8, the vertical main reinforcement 4 is marked with a marker pen, and the bottom plate of the wooden box structure 3 is first penetrated into the reinforcement used for the construction of the underground diaphragm wall 7 The corresponding position (mark) of the vertical main reinforcement 4 of the cage, and the square wood skeleton device 1 with a size of 100mm*100mm processed in advance is fixed horizontally on the vertical main reinforcement 4, and the bottom plate of the wooden box structure 3 is the same as the square wood The frame d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com