Titanium oxide with core-shell structure and its controllable preparation method

A titanium oxide, core-shell structure technology, applied in the field of materials science, to achieve the effects of controllable microscopic structural units, improved electrocatalytic performance, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

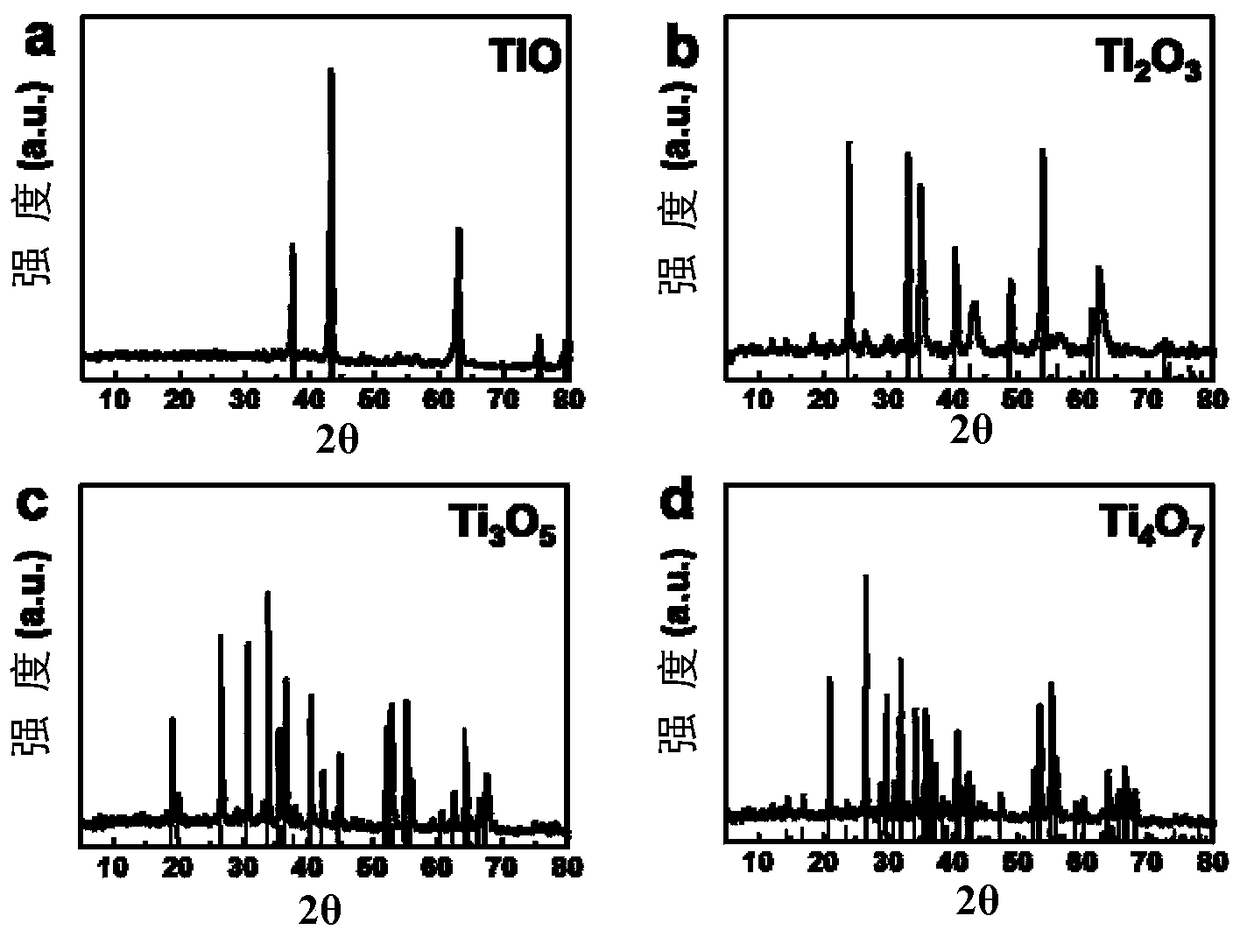

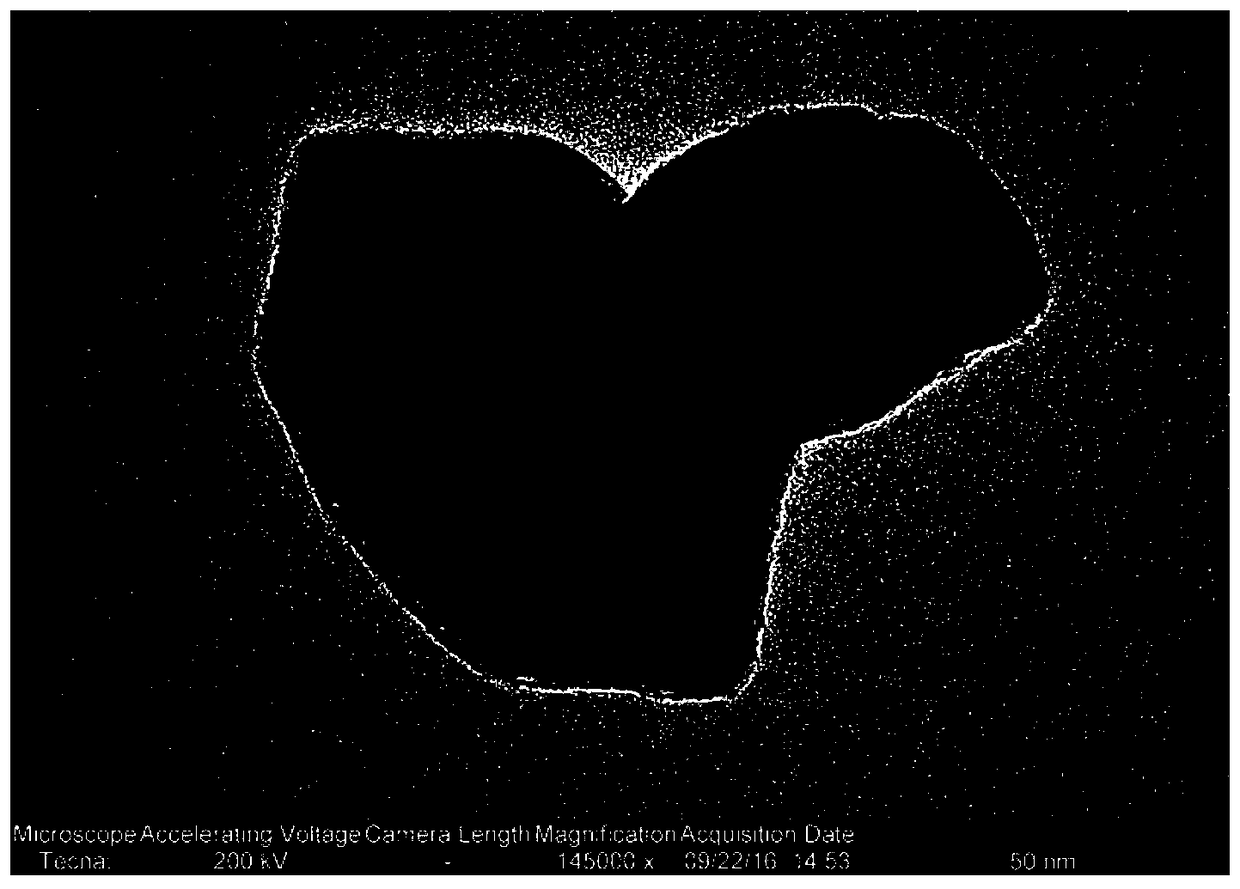

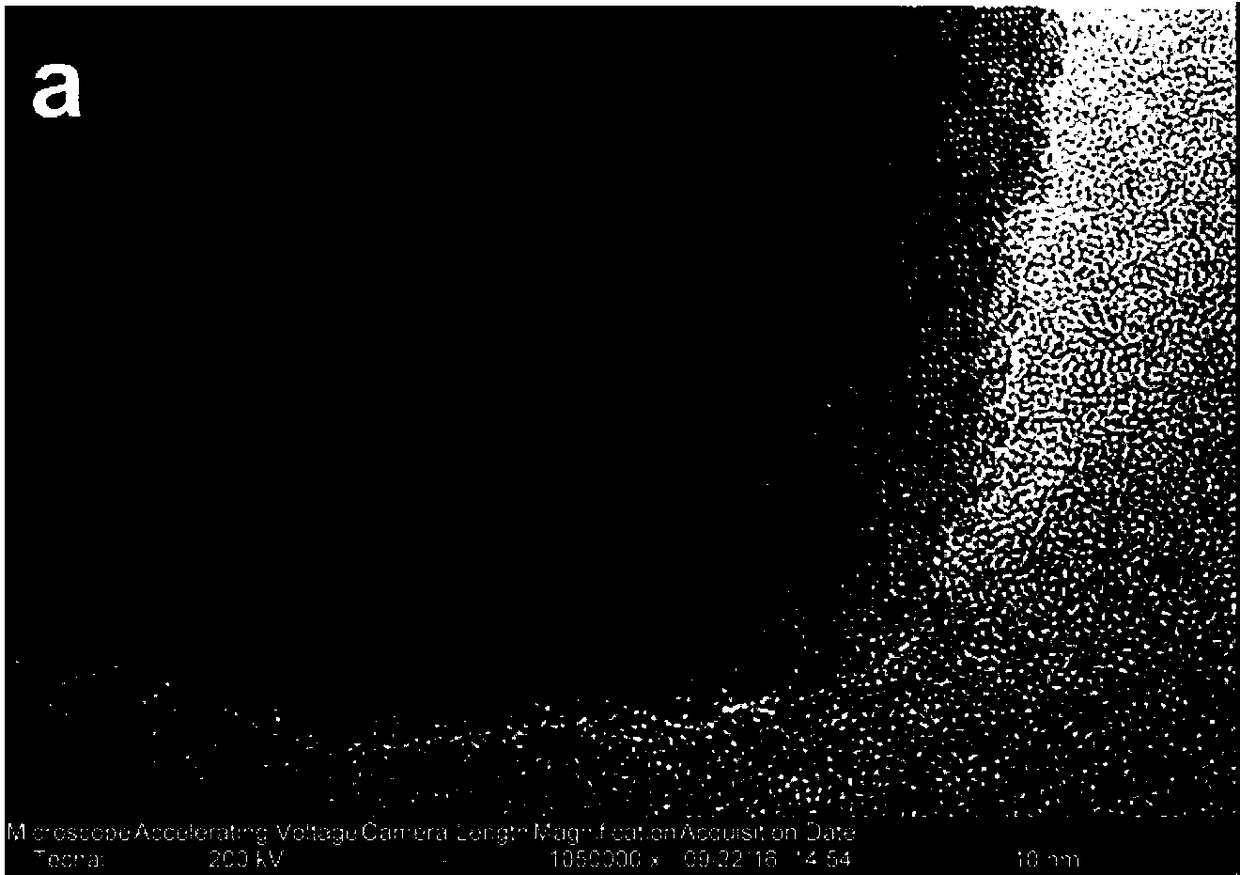

[0031] The invention provides a titanium oxide with a core-shell structure coated with an amorphous layer on the surface and a method for preparing the pure phase of the titanium oxide under low temperature conditions with low cost and controllable control. The reduction of titanium dioxide by an active metal enables the controllable preparation of titanium dioxide at a relatively low temperature (550°C). The TiO prepared under this low-temperature condition has a unique core-shell structure covered by an amorphous layer on the surface, and has excellent electrocatalytic oxygen reduction performance.

[0032] In the present invention, as long as titanium dioxide can be transformed into a rutile phase by a suitable method, the microscopic morphology of titanium dioxide (rutile titanium dioxide) includes but is not limited to various shapes such as balls, rods, strips, tubes and irregular polygons.

[0033] In the present invention, the particle diameter of titanium dioxide may ...

Embodiment 1

[0060] (1) Titanium dioxide is used as a precursor, and metal magnesium is used as a reducing agent, wherein, in terms of molar percentage, metal magnesium: TiO 2 =55% weighed and ground and mixed in a mortar;

[0061] (2) Add the uniformly mixed powder into a quartz tube with an open end, connect a vacuum pump to make the vacuum less than 1 Pa, and then use a hydrogen-oxygen flame gun to melt and seal the open end of the quartz tube;

[0062] (3) Place the vacuum-tight quartz tube in a muffle furnace, raise the temperature from 30°C to 450°C at a rate of 1°C / min, keep it warm for 6 hours, and then rise from 450°C to 550°C at a rate of 1°C / min ℃, keep warm for 6 hours and then cool with the furnace;

[0063] (4) Open the vacuum-tight quartz tube, mix the gained black powder with water and stir for 6 hours, remove part of the incompletely reacted metal;

[0064](5) Suction filter the stirred solution, add 1M dilute hydrochloric acid, mix and stir for 6 hours, add deionized wa...

Embodiment 2

[0066] (1) Titanium dioxide is used as a precursor, and metal magnesium is used as a reducing agent, wherein, in terms of molar percentage, metal magnesium: TiO 2 =105% weighed and ground in a mortar and mixed evenly;

[0067] (2) Add the uniformly mixed powder into a quartz tube with an open end, connect a vacuum pump to make the vacuum less than 1 Pa, and then use a hydrogen-oxygen flame gun to melt and seal the open end of the quartz tube;

[0068] (3) Place the vacuum-tight quartz tube in a muffle furnace, raise the temperature from 30°C to 450°C at a rate of 1°C / min, keep it warm for 6 hours, and then rise from 450°C to 550°C at a rate of 1°C / min ℃, keep warm for 6 hours and then cool with the furnace;

[0069] (4) Open the vacuum-tight quartz tube, mix the gained black powder with water and stir for 6 hours, remove part of the incompletely reacted metal;

[0070] (5) Suction filter the stirred solution, add 1M dilute hydrochloric acid, mix and stir for 6 hours, add dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com