Purification method of lithium bis(fluorosulfonyl)imide

A technology for the purification of lithium bisfluorosulfonyl imide, which is applied in the direction of nitrosyl chloride, nitrogen and non-metallic compounds, etc., can solve the problems of easy decomposition, difficulty, and poor thermal stability of substances, and achieve high purity and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 200 g of butyl acetate and 37.4 g (0.2 mol) of crude lithium bisfluorosulfonyl imide (purity 98.1%, moisture 0.5%) into 500 mL reaction flask A, stir to dissolve, and filter to remove insoluble matter.

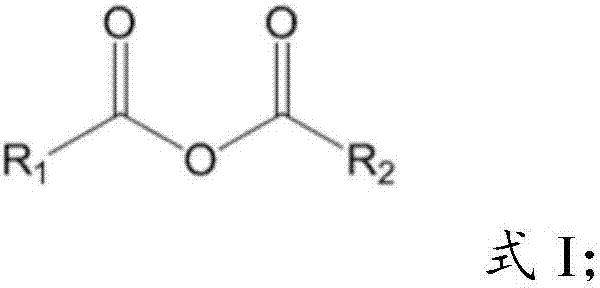

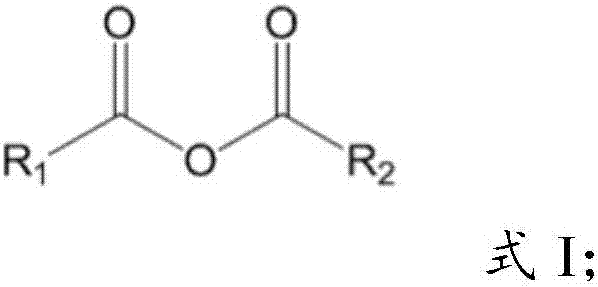

[0041] In the 500mL reaction flask B, add the filtered filtrate, add acetic anhydride 10g (R in formula I 1 and R 2 Both are -CH 3 compound) was passed through dry nitrogen, and stirred at 50°C for 3h. The treated solution was transferred and concentrated by evaporation under reduced pressure until the remaining 60 g of the solution was concentrated. The concentrated solution was transferred to an anhydrous glove box, 120 g of dichloromethane was added thereto, stirred for 0.5 h, left to stand for crystallization, and filtered after 12 h. The obtained crystal weighed 25.2 g after vacuum drying to obtain a pure product. The yield of the purification method provided by Example 1 of the present invention is 67.4%, the water content in the pure product is 52ppm, and ...

Embodiment 2

[0043] Add 200 g of dimethyl carbonate and 37.4 g (0.2 mol) of crude lithium bisfluorosulfonyl imide (purity 98.1%, moisture 0.5%) into 500 mL reaction flask A, stir to dissolve, and filter to remove insoluble matter.

[0044] In the 500mL reaction bottle B, add the filtered filtrate, add trifluoroacetic anhydride 10g (R in formula I 1 and R 2 Both - CF 3 compound) was passed through dry nitrogen, and stirred at 60°C for 3h. The treated solution was transferred and concentrated by evaporation under reduced pressure until the remaining 60 g of the solution was concentrated. The concentrated solution was transferred to an anhydrous glove box, 120 g of toluene was added thereto, stirred for 0.5 h, left to stand for crystallization, and filtered after 12 h. The obtained crystal weighed 26.3g after vacuum drying to obtain a pure product. The yield of the purification method provided by Example 2 of the present invention is 70.3%, the water content in the pure product is 37ppm, a...

Embodiment 3

[0046] Add 200 g of diethyl ether and 37.4 g (0.2 mol) of crude lithium bisfluorosulfonyl imide (98.1% purity, 0.5% moisture) into 500 mL reaction flask A, stir to dissolve, and remove insoluble matter by filtration.

[0047] In the 500mL reaction bottle B, add the filtered filtrate, add trifluoroacetic anhydride 50g (R in formula I 1 and R 2 Both - CF 3 compound), heated to about 34° C. and stirred for 3 h under dry nitrogen gas. The treated solution was transferred and concentrated by evaporation under reduced pressure until the remaining 45 g of the solution was stopped. The concentrated solution was transferred to an anhydrous glove box, 150 g of dichloromethane was added thereto, stirred for 0.5 h, left to stand for crystallization, and filtered after 12 h. The obtained crystal weighed 29.2g after vacuum drying to obtain a pure product. The yield of the purification method provided by Example 3 of the present invention is 78.1%, the water content in the pure product is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com