Shocking discharge system of dump truck for bonding materials

A technology for bonding materials and dump trucks. It is applied in the direction of loading and unloading vehicles, motor vehicles, and transporting objects. It can solve the problems of labor cost, maximum lifting angle limitation, and low dumping efficiency, so as to improve efficiency, reduce impact, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

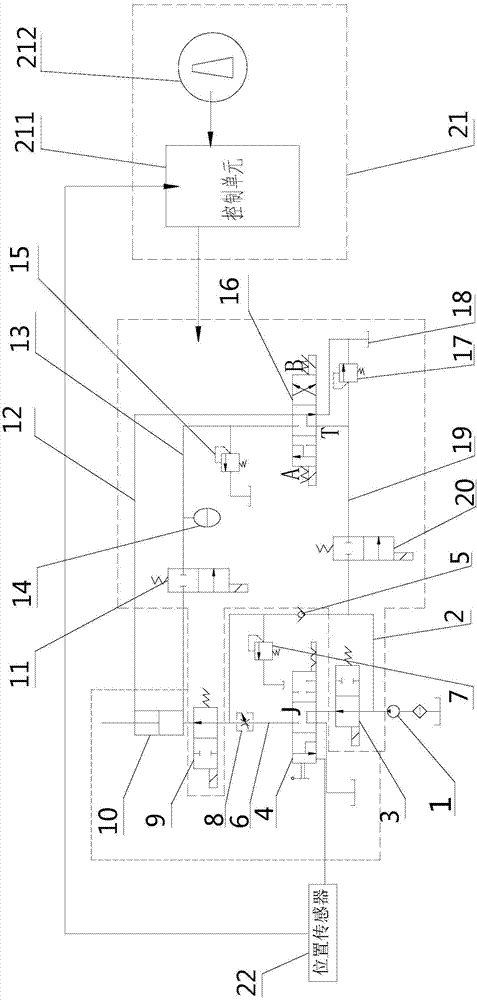

[0021] see figure 1 , this embodiment discloses a vibrating and unloading system for sticky materials of a dump truck. The vibrating unloading system is used in conjunction with a hydraulic lifting system. The hydraulic lifting system includes a fuel tank 18, a hydraulic pump 1, a hydraulic cylinder 10, and a hydraulic lifting system connected to the hydraulic pump 1. The hydraulic lifting pipeline 2 and the hydraulic descending pipeline 6 between the hydraulic cylinder 10, the hydraulic cylinder 10 includes a cylinder body and a piston rod, and the cylinder body is divided into an upper chamber and a lower chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com