Carrying mechanical hand with rod type parallel series connection structure

A serial structure, manipulator technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as affecting the working efficiency and accuracy of handling manipulators, poor dynamic performance of robots, and increasing the load of drive motors, reducing the difficulty of control programming. , Improve the handling accuracy and speed, and improve the effect of dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

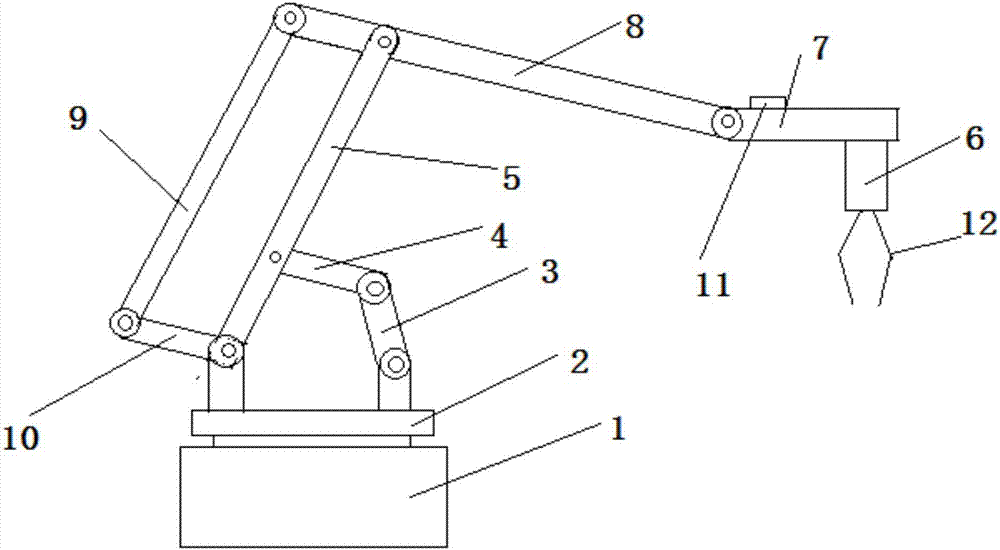

[0007] A rod-type parallel-series structure handling manipulator according to the present invention includes a base 1, a rotary platform 2, a first active rod 3, a second active rod 10, a large arm 5, a large arm connecting rod 4, and a middle arm connecting rod 9 , middle arm 8, forearm 7, wrist 6, hand claw 12, inclination detector 11 and driving device; One end of the first active rod 3 is connected with the rotary platform 2, and the other end of the first active rod 3 is connected with the big arm connecting rod 4 is connected at one end, the other end of the boom connecting rod 4 is connected with one end of the boom 5, one end of the second active rod 10 is connected with the rotary platform 2, the other end of the second active rod 10 is connected with the middle arm connecting rod 9, and the middle arm connecting rod 9 The other end is connected with one end of the middle arm 8, one end of the big arm 5 is connected with the rotary platform 2, the other end of the big ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com