Atmospheric plasma system used for tubular material surface continuous modification

A normal-pressure plasma, tubular technology, applied in the direction of plasma, electrical components, etc., can solve the problems of low energy utilization rate, poor treatment uniformity, high price, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

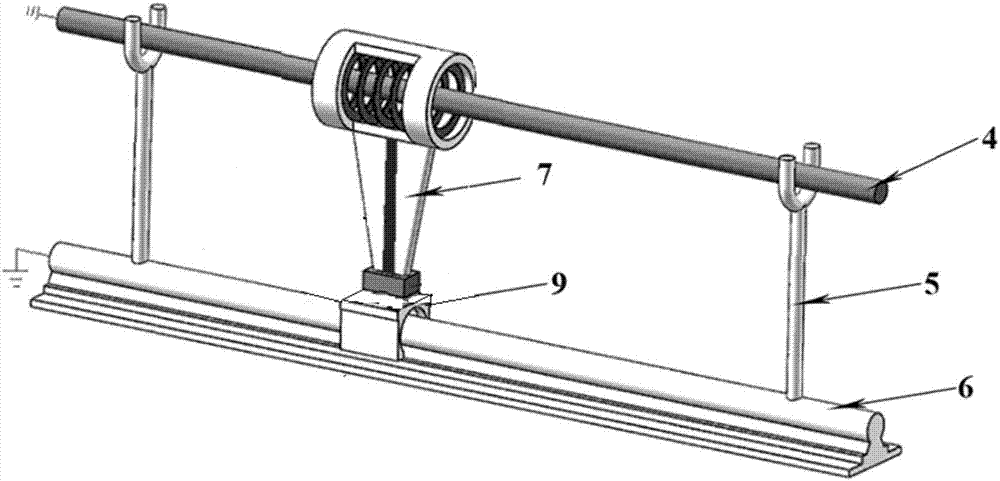

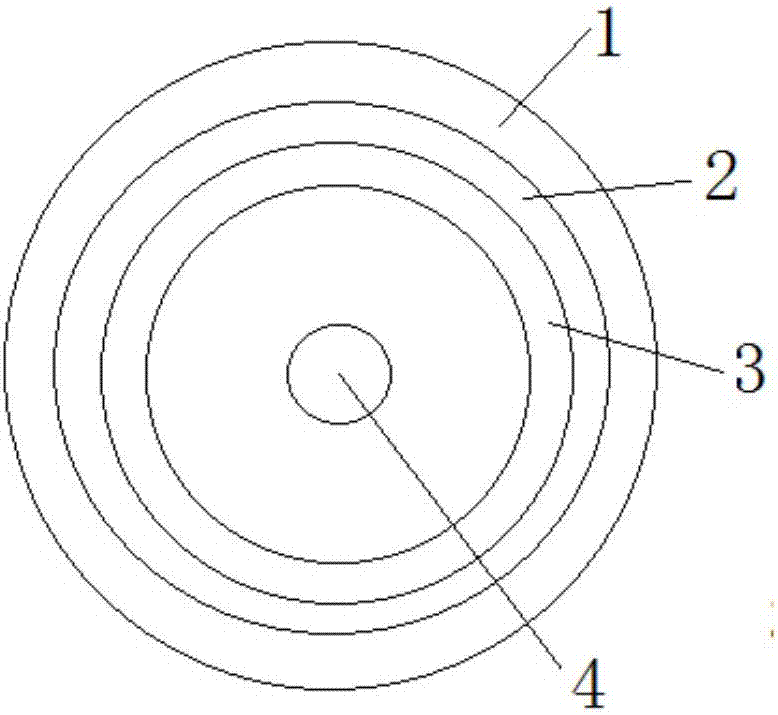

[0010] Such as figure 1 As shown, an atmospheric pressure plasma system for continuous surface modification of tubular materials includes a cylindrical electrode, a high-voltage power supply, a guide rail 6, two insulating support frames 5 installed at both ends of the guide rail, and a Guide rail slider 9, a motor installed inside the guide rail slider, and a support plate 7 installed above the guide rail slider; the cylindrical electrode is horizontally installed on the top of the support plate 7 and connected to a high-voltage power supply; the cylinder The shape electrode consists of a ceramic layer 3, a metal layer 2 and a polytetrafluoroethylene layer 1 sequentially from the inside to the outside. Under the action of the motor, the cylindrical electrode moves horizontally on the guide rail 6 to continuously modify the tubular material 4 (connected to the ground wire) to be processed inside it.

[0011] Place the two ends of the polished stainless steel tube for the flus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com