Integrated constant temperature heating plate

A heating plate and constant temperature heating technology, which is applied in the field of home heating, can solve the problems of failure to meet the constant temperature standard, shorten the service life of the heating plate, and unstable temperature, so as to achieve the effect of enhancing uniform heat dissipation and reducing the barrier and heating effect of heat energy fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

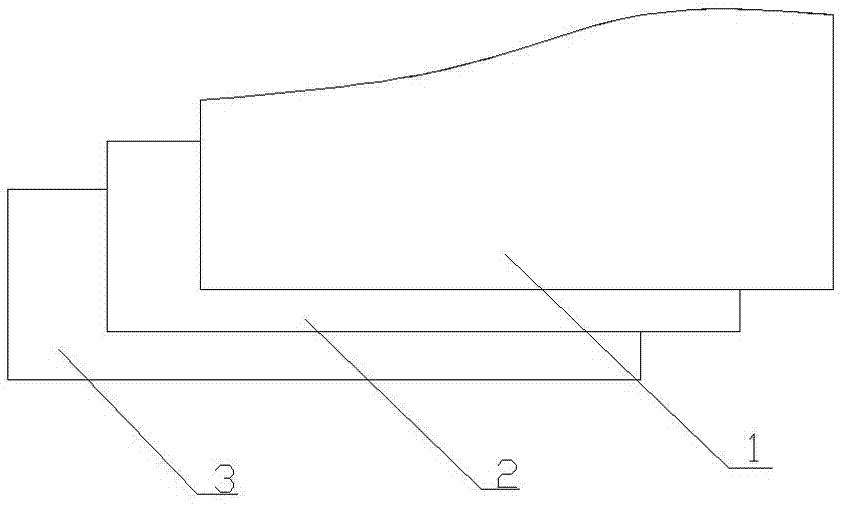

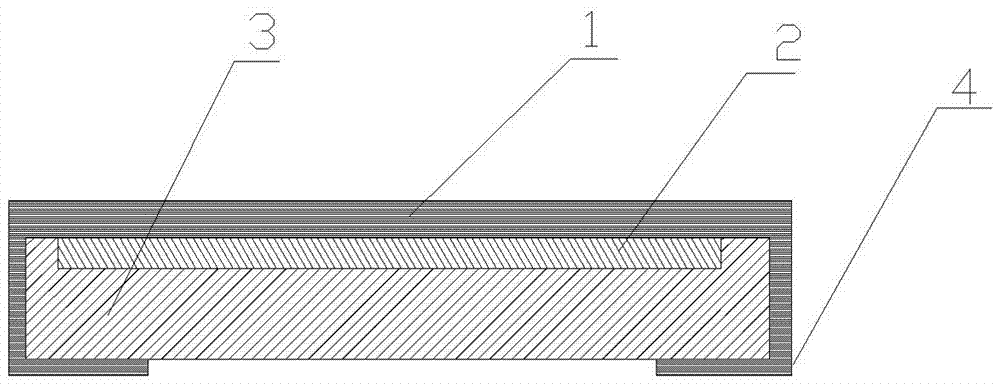

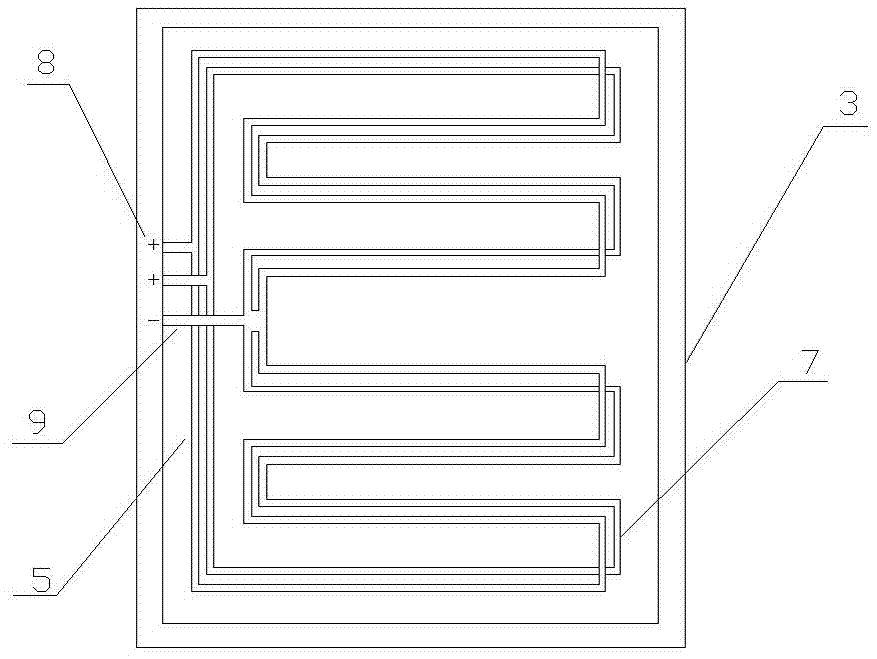

[0023] As shown in the figure, an integrated constant temperature heating plate includes a heat conducting plate 1, a heating layer 2 arranged on the back of the heat conducting plate 1, and an insulation layer 3 covering the back of the heating layer 2 and both ends. The heat conducting plate is made of stainless steel, aluminum or galvanized Metal, the three adjacent sides of the heat conduction plate 1 are bent toward the back to form a bend plate 4, the cross section of the bend plate 4 is "L" shaped, and the heating layer 2 and the heat preservation layer 3 are installed on the back of the bend plate 4 and the heat conduction plate 1 In the enclosed space, that is, the plane of the bending plate 4 and the heat conducting plate 1 is arranged in a "U" shape, and there is no need to worry about deformation and collapse due to improper support and installation of the heating plate or the excessive gravity of the heating plate itself. Its mechanical strength is improved, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com