Efficient flame retardant device

A fire-blocking and efficient technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of cutting off the gas source, difficult to detect, etc., to avoid back channeling, improve sensitivity, and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

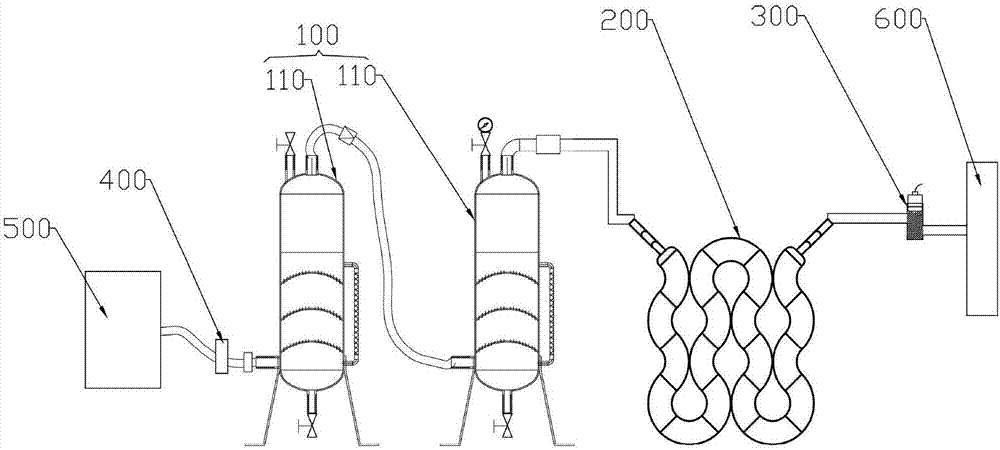

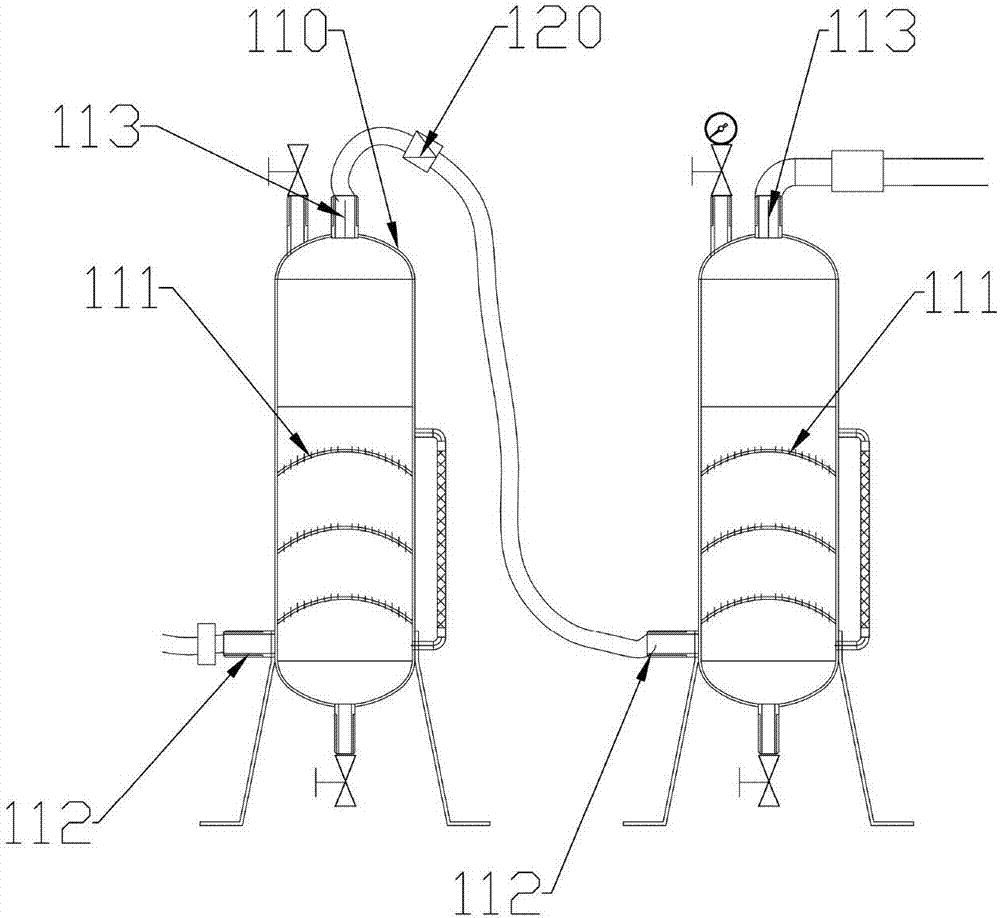

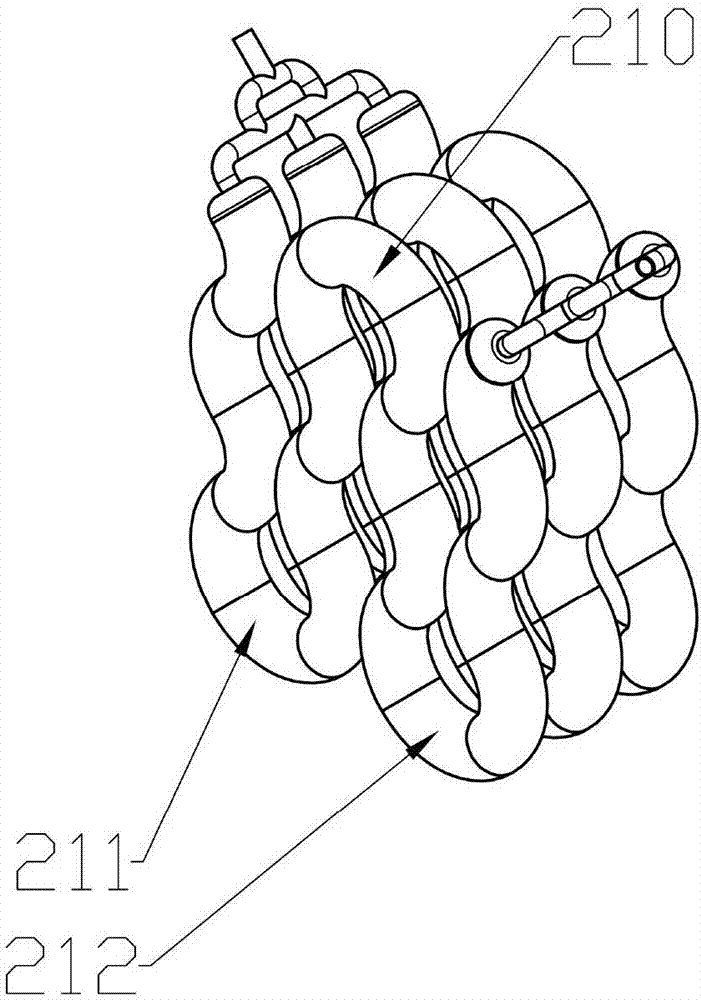

[0017] refer to figure 1 , a high-efficiency fire arresting device, the high-efficiency fire arresting device is installed between the gas supply end 500 and the use end 600, the gas supply end 500 supplies hydrogen-oxygen mixed gas, from the gas supply end 500 to the use end 600, the high-efficiency fire arresting device sequentially includes an electronic check valve 400, a water-type fire arresting mechanism 100, a dry-type fire arresting mechanism 200, and the free radical detection device 300, and the free radical detection device 300 is connected to the The electronic check valves 400 are respectively electrically connected to the controller, and the controller controls the opening and closing of the electronic check valves 400 according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com