Power system of cam rotor internal combustion engine

An internal combustion engine and power system technology, applied in the directions of internal combustion piston engine, combustion engine, rotary piston engine, etc., can solve the problems of limited scalability of triangular rotor internal combustion engine structure, difficult to improve rotor shaft torque, and high processing requirements for core parts , to achieve the effect of short motion transmission link, simple structure and large parameter range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

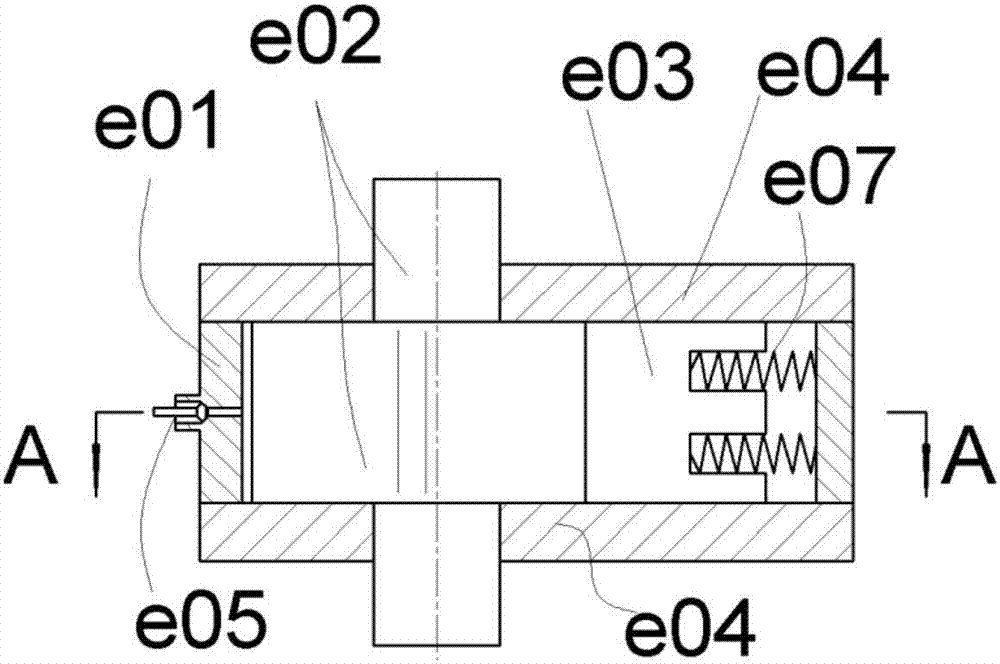

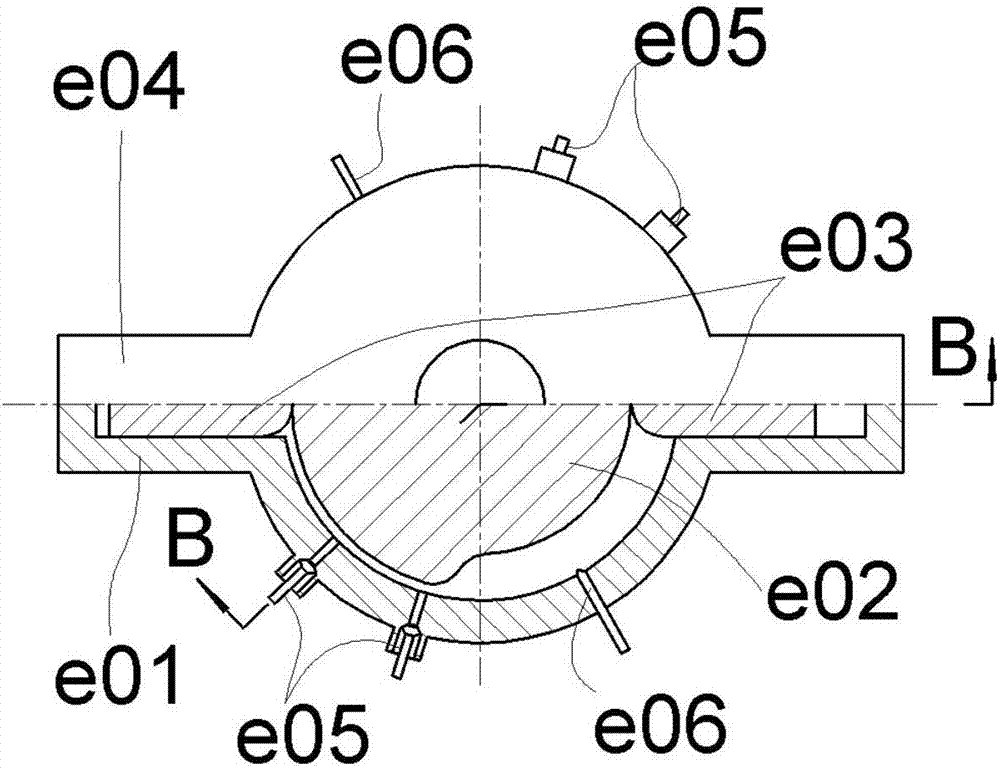

[0038] See figure 1 and figure 2 , figure 1 is the front view of a basic structure, and its top view corresponds to the attached figure 2 , and correspond to figure 2 The B-B profile, figure 2 correspond figure 1 The A-A profile. The rotor housing e01 has an inner cylindrical surface, and the cam is an outer contour disc cam with a section of far rest area and a section of near rest area, which is integrated with the rotary shaft to form the rotor e02. The far rest area and the near rest area are both close to 180°. The cam follower is the straight-moving slider e03, the number is 2, the slider e03 is installed in the sliding radial chute in the rotor chamber, and the spring e07 is used to realize force closure. Due to the small number of sliders, no slider escapement is added . The end member e04 is sealed and fixed with the rotor chamber and forms a dynamic seal with the end surface of the cam. There is a gap between the far resting area of the cam and the inner...

Embodiment 2

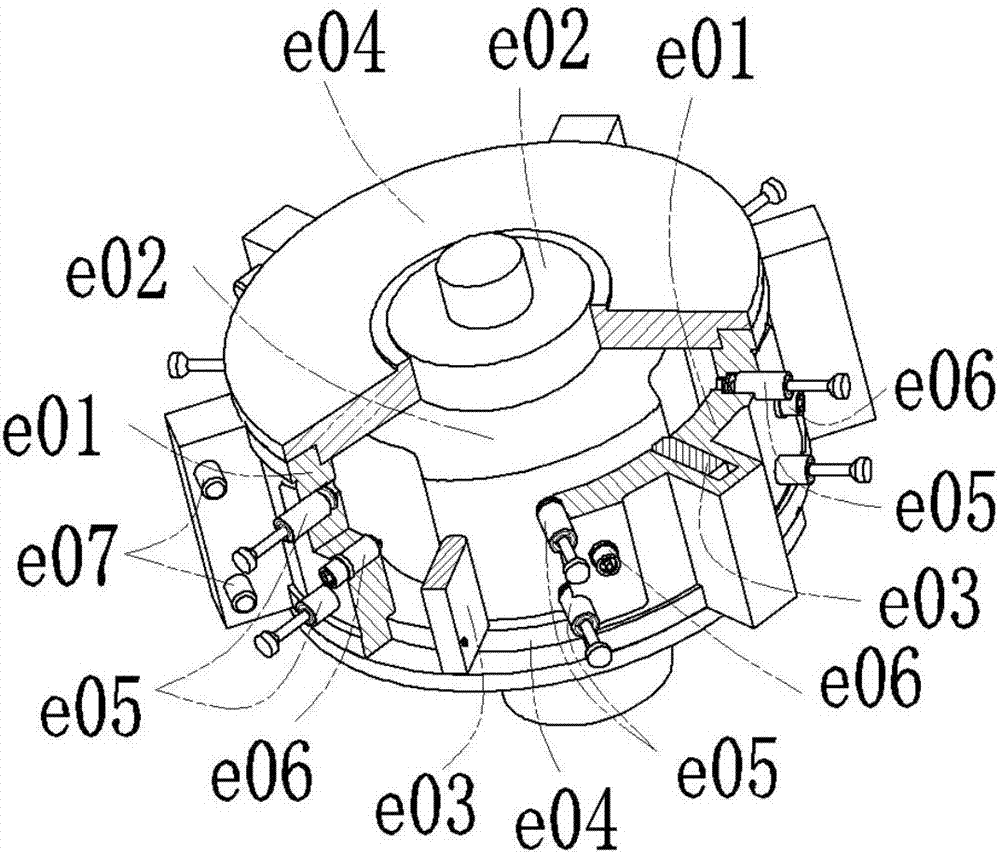

[0041] See image 3 In this example, on the basis of the structure of Embodiment 1, the number of cam follower sliders e03 is increased to 6, uniformly distributed in the circumferential direction, and a slider escapement is set; the cam profile on the rotor e02 is far from the rest area and near The rest area is increased into two sections, which are arranged symmetrically in the circumferential direction. The arc length and centripetal angle of the far rest section are about 70°, slightly larger than the corresponding centripetal angles of the two adjacent sliders, and the centripetal angles of the near rest area are about 90°. . Sealing structure relation is the same as previous example, no longer repeats. The sliding block groove and the end member e04 also form an independent sealing chamber, which can be fed with compressed air or hydraulic oil to realize force sealing between the sliding block and the cam profile; the intake and exhaust ports e05 with valves and the ig...

Embodiment 3

[0058] See Figure 5 , the inner profile cam and the inner cylindrical surface shell are combined to form the inner profile cam rotor e01. The inner profile cam is a straight generatrix disc shape, with two sections of near rest area and two sections of far rest area, symmetrically arranged in the circumferential direction, and the arc length of the near rest section The centripetal angle is about 70°, and the centripetal angle of the far rest zone is about 90°. The cam follower pendulum e03 is installed on the center fixing frame e02 of the outer cylindrical surface, and the number of pendulum pieces is 6 evenly distributed, that is, the arc length of the near-rest segment and the centripetal angle are slightly larger than the centripetal angles between adjacent pendulum pieces. There is a gap between the near-rest section of the inner contour cam and the outer cylindrical surface of the central fixed frame e02, and the upper and lower end members e04 are sealed and fixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com