Non-fluidity rapid-hardening strong-cohesive-force phosphate cement repairing material and preparation method thereof

A technology of phosphate cement and repair materials, which is applied in the field of non-fluid quick-setting strong cohesion phosphate cement repair materials and its preparation, which can solve the problems of short setting time and achieve convenient transportation, significant economic benefits and social benefits , the effect of increasing the overall stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Phosphate cement-based rapid repair material, firstly mix 5% ammonium dihydrogen phosphate, 20% magnesium oxide, 2% fly ash, 30% rubber powder, 6% silica fume, 0.4% polycarboxylic acid Put water reducer, 1.6% sodium silicate, and 0.5% retarder into the mixer and stir evenly, then put 25% of sand into the mixer and mix evenly, then add 8% of water into the mixing drum, add the required Slowly, after all the water is added, keep stirring for 1-2 minutes until a uniform paste with good fluidity is formed, then add 1.5% polypropylene fiber and stir for 30 seconds, then it can be prepared into phosphate cement-based quick repair Material.

[0016] The fly ash test results are shown in Table 1.

[0017] Table 1 Fly ash test results.

[0018]

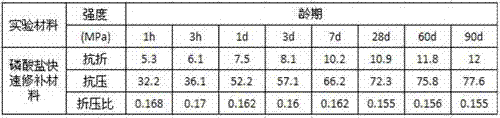

[0019] 1. Performance test results of phosphate cement-based rapid repair materials.

[0020] 1. Setting time.

[0021] The experimental equipment adopts the instruments and appliances specified in GB1346 "Cement Standard Consist...

Embodiment 2

[0029] Phosphate cement-based rapid repair material, sand 20%, ammonium dihydrogen phosphate 6%, magnesium oxide 18%, fly ash 3%, rubber powder 32%, silica fume 7%, polycarboxylate superplasticizer 0.5%, Sodium silicate 1.5%, polypropylene fiber 2%, retarder 1%, water 9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com