Automatic separator for autoclaved aerated concrete building blocks

A concrete block and automatic separation technology, which is applied in the direction of conveyors, object stacking, object destacking, etc., can solve the problems of single mechanical function and inability to separate concrete blocks, etc., achieve high separation efficiency and eliminate accidents Possibility, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

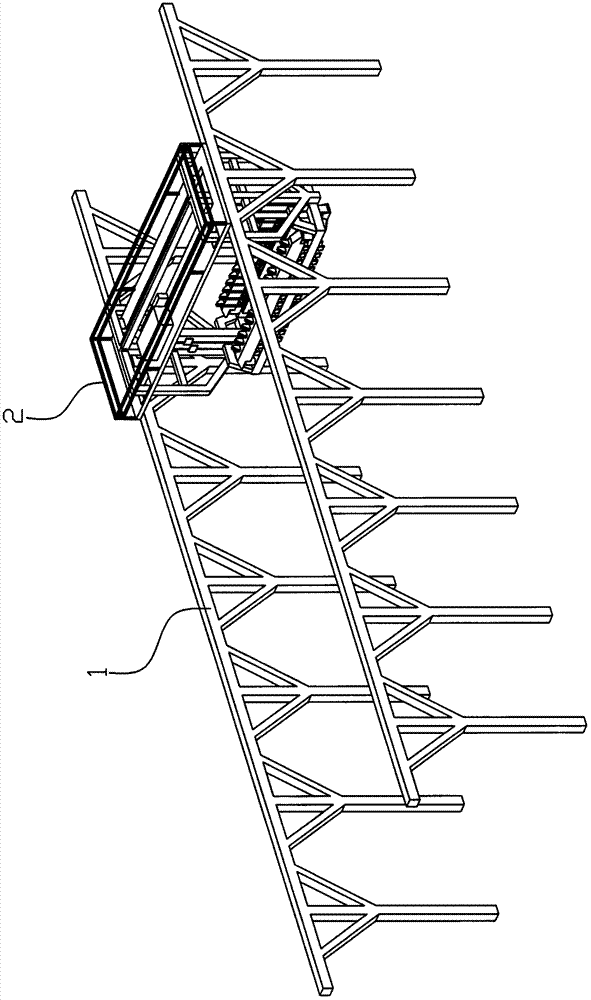

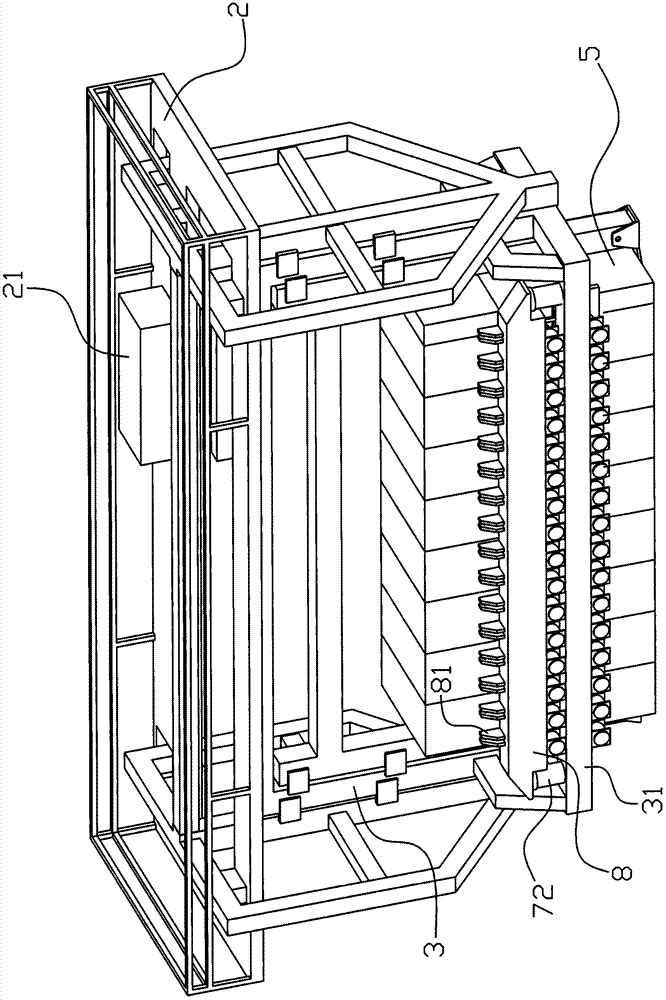

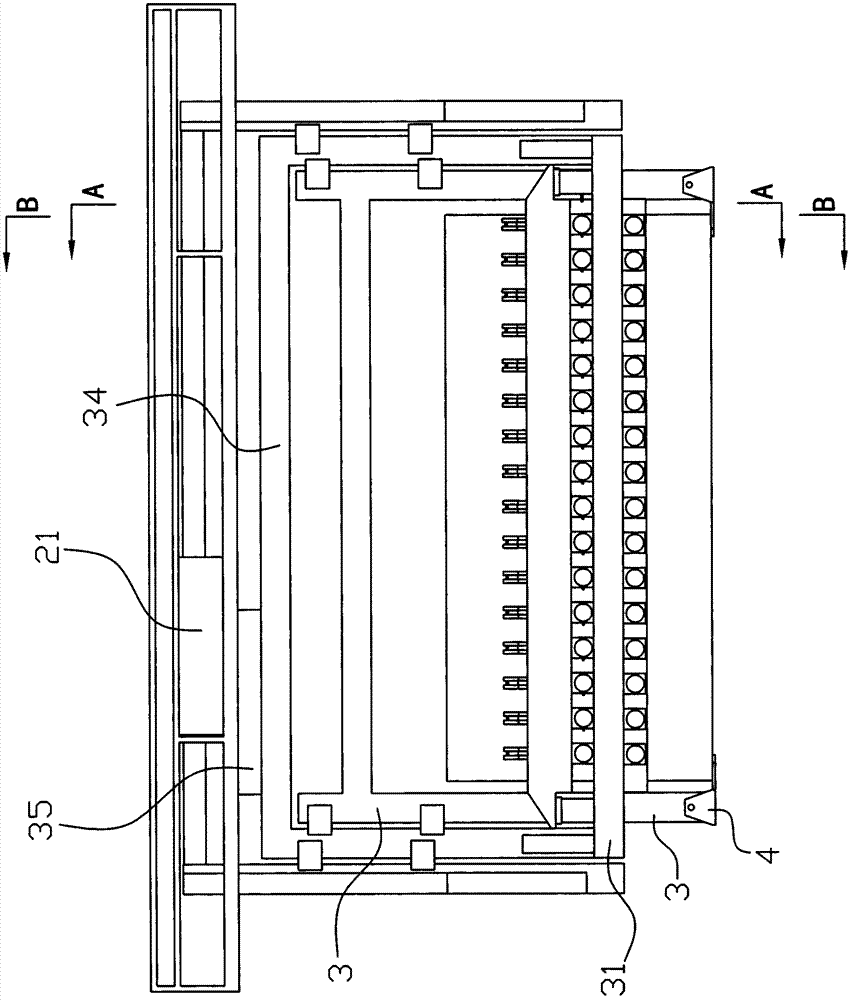

[0028] Such as Figure 1 to Figure 12As shown, the automatic separator of autoclaved aerated concrete blocks in this embodiment includes a body that can move left and right along the guide rail 1 through a driving device. The body includes a frame 2 that can be clamped left and right when placed in the frame 2 The clamping device of the concrete block is placed in the frame 2 and can vertically move the concrete block 5 up and down to the position of the clamping device. The clamping device includes an upper clamping part and a lower clamping part. The upper clamping part can move upwards through the upper driving part, and the up and down moving device and the clamping device are respectively connected with the control circuit through lines; when the concrete block 5 is moved between the upper clamping part and the lower clamping part , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com