Silver oxide nano particle/molybdenum sulfide nanosheet heterostructure ultrasonic near infrared catalyst and preparation method thereof

A nanoparticle and heterostructure technology is applied in the field of silver oxide nanoparticle/molybdenum sulfide nanosheet heterostructure and its preparation, and achieves the effects of short reaction period, high efficiency and excellent near-infrared photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] First, measure 0.5 mole of silver nitrate solution, weigh 1.0 mole of molybdenum sulfide nanosheets, add the silver nitrate solution and molybdenum sulfide nanosheets into deionized water and fully dissolve to prepare the first mixed solution. Then measure 0.25 moles of sodium hydroxide solution, drop the sodium hydroxide solution into the first mixed solution, then add the first mixed solution with sodium hydroxide solution dropwise for 0.5 hours by magnetic stirring, and prepare the second mixed solution liquid. Immediately after filtering the second mixed solution to obtain a precipitate, the obtained precipitate was washed with deionized water, and then the washed precipitate was vacuum-dried at 60° C. for 12 hours, and finally the prepared silver oxide nanoparticles were taken out / Molybdenum sulfide nanosheet heterostructure.

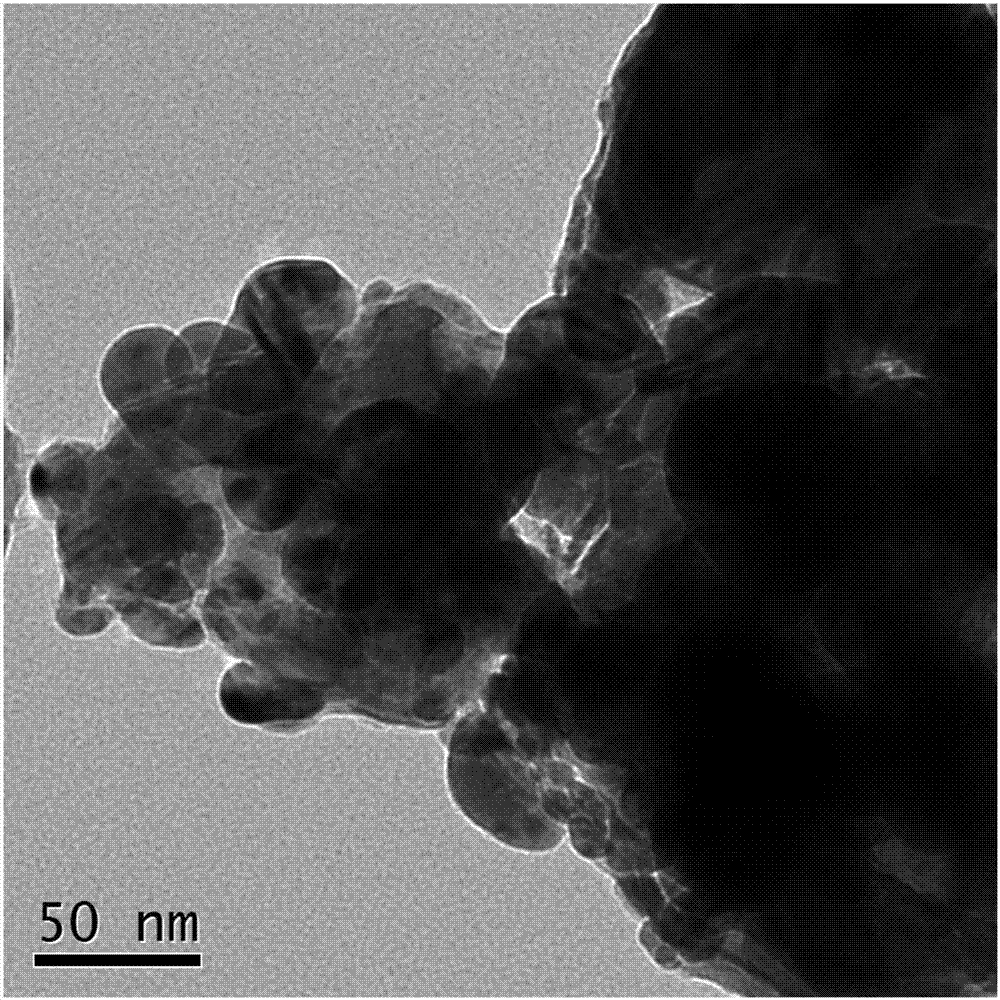

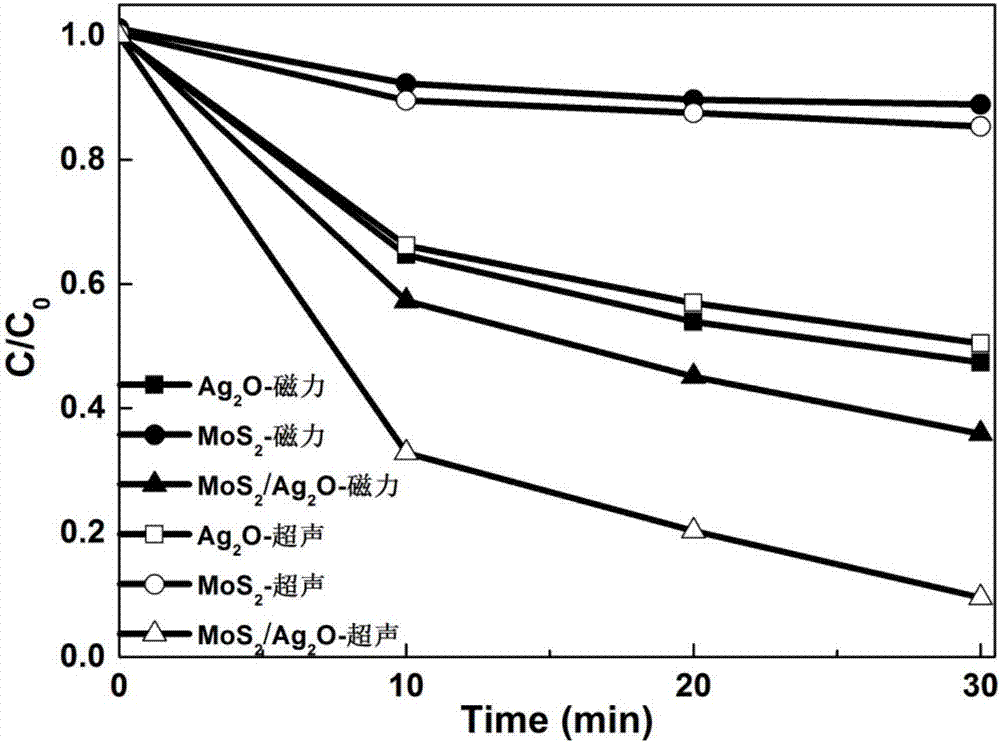

[0040] In the silver oxide nanoparticle / molybdenum sulfide nanosheet heterostructure prepared in Example 1 above, the silver oxide nanopa...

Embodiment 2

[0042] First, measure 1.0 mole of silver nitrate solution, weigh 1.0 mole of molybdenum sulfide nanosheets, add the silver nitrate solution and molybdenum sulfide nanosheets into deionized water and fully dissolve to prepare the first mixed solution. Then measure 0.5 mole of sodium hydroxide solution, drop the sodium hydroxide solution into the first mixed solution, and then add the first mixed solution with sodium hydroxide solution dropwise for 0.25 hours by magnetic stirring to prepare the second mixed solution liquid. Immediately after filtering the second mixed solution to obtain a precipitate, the obtained precipitate was washed with deionized water, and then the washed precipitate was vacuum-dried at 60° C. for 12 hours, and finally the prepared silver oxide nanoparticles were taken out / Molybdenum sulfide nanosheet heterostructure.

[0043] In the silver oxide nanoparticle / molybdenum sulfide nanosheet heterostructure prepared in Example 2 above, the silver oxide nanop...

Embodiment 3

[0045] First, measure 1.0 mole of silver nitrate solution, weigh 1.0 mole of molybdenum sulfide nanosheets, add the silver nitrate solution and molybdenum sulfide nanosheets into deionized water and fully dissolve to prepare the first mixed solution. Then measure 0.5 mole of sodium hydroxide solution, drop the sodium hydroxide solution into the first mixed solution, then add the first mixed solution with sodium hydroxide solution dropwise for 0.5 hours by magnetic stirring, and prepare the second mixed solution liquid. Immediately after filtering the second mixed solution to obtain a precipitate, the obtained precipitate was washed with deionized water, and then the washed precipitate was vacuum-dried at 60° C. for 12 hours, and finally the prepared silver oxide nanoparticles were taken out / Molybdenum sulfide nanosheet heterostructure.

[0046] The silver oxide nanoparticle / molybdenum sulfide nanosheet heterostructure obtained in the above-mentioned Example 3 is grown in liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com