Built-in superfine dry powder fire-extinguishing device

A technology of ultra-fine dry powder and fire extinguishing device, which is applied in fire rescue and other directions, can solve the problems of limited installation position, increased work difficulty, large appearance and volume, etc., and achieve the effect of convenient tripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

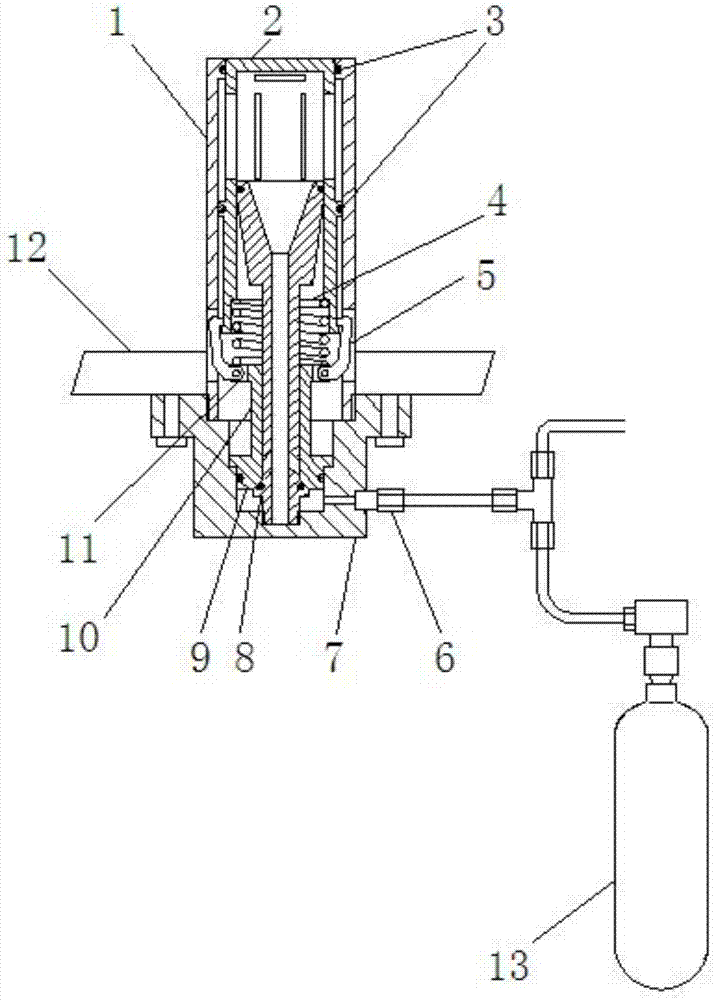

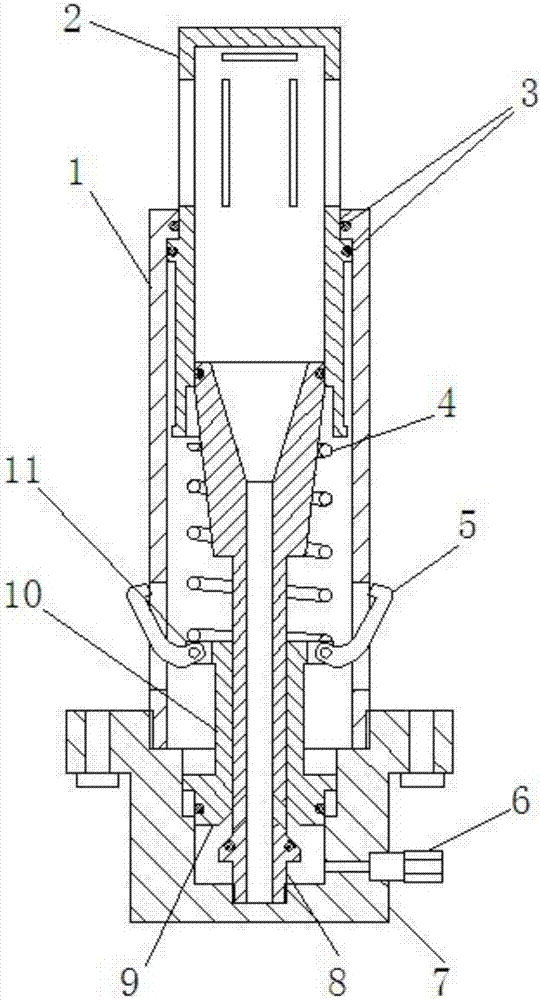

[0024] Such as Figure 1 to Figure 3 As shown, an embodiment of a built-in ultrafine dry powder fire extinguishing device of the present invention includes a fixed seat 7, an outer cylinder 1, an inner barrel 2, a nozzle 8 and a piston member 10, and the fixed seat 7 is a barrel-shaped structure with an open end , the side wall of the fixed seat 7 is provided with an air inlet; The opening of the inner barrel 2 is filled with ultra-fine dry powder, and the inner barrel 2 is slidably assembled on the inner side of the outer barrel 1, and a plurality of injection holes are arranged on the side wall of the inner barrel 2 near its blind end; one end of the nozzle 8 is a connecting end , the other end is the injection end, the connection end of the nozzle pipe 8 is fixedly connected to the bottom end of the inner side of the fixed seat 7, the injection end of the nozzle pipe 8 stretches into the inner barrel 2, and the injection end of the nozzle pipe 8 is provided with a bell mout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com