Permanent magnetism motor rotor and motor

A permanent magnet motor and rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electrical components, etc., can solve the problem that the supporting force cannot resist centrifugal force, etc., to ensure the strength, solve the magnetic leakage, and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

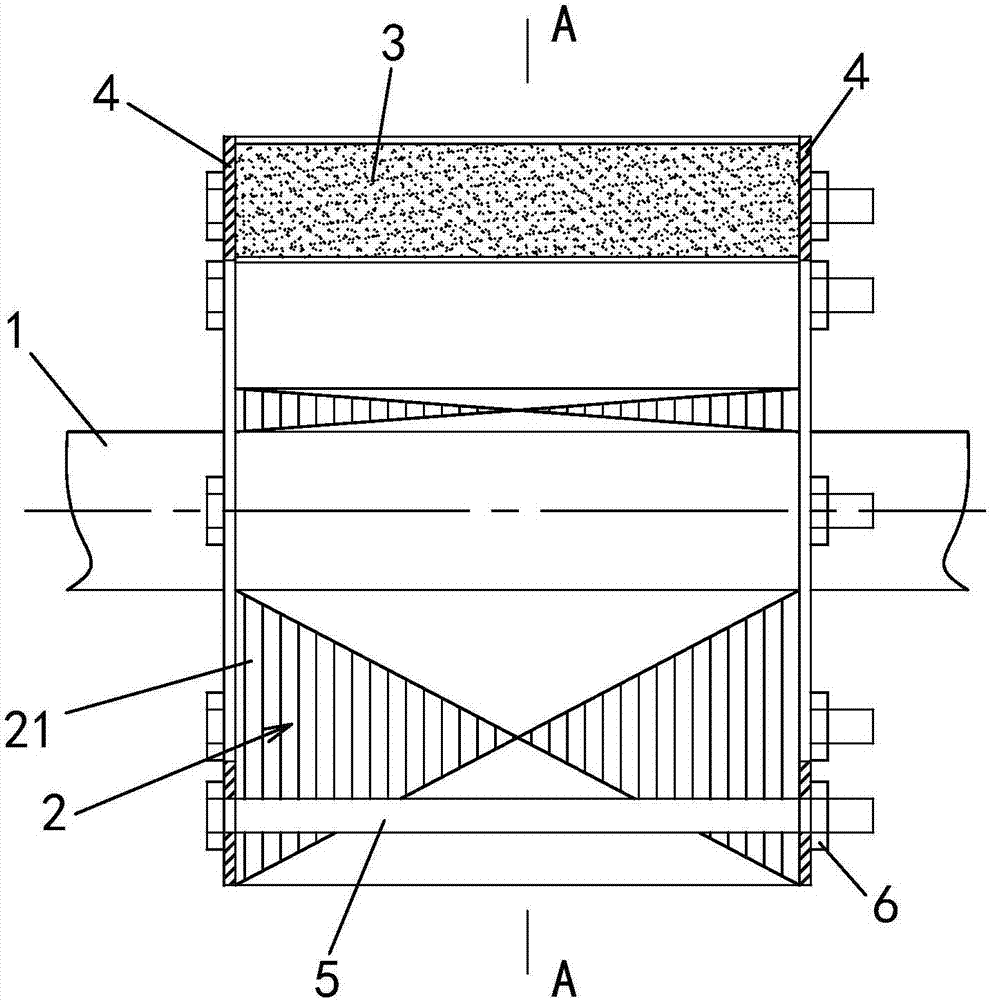

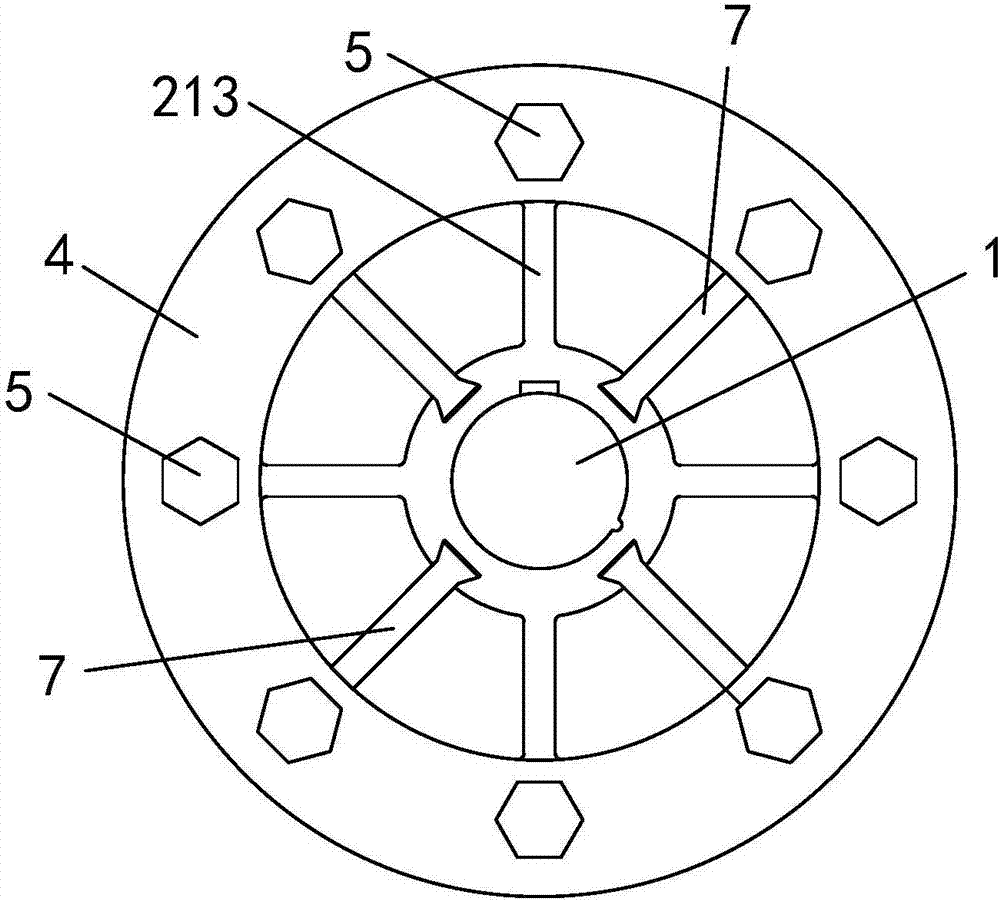

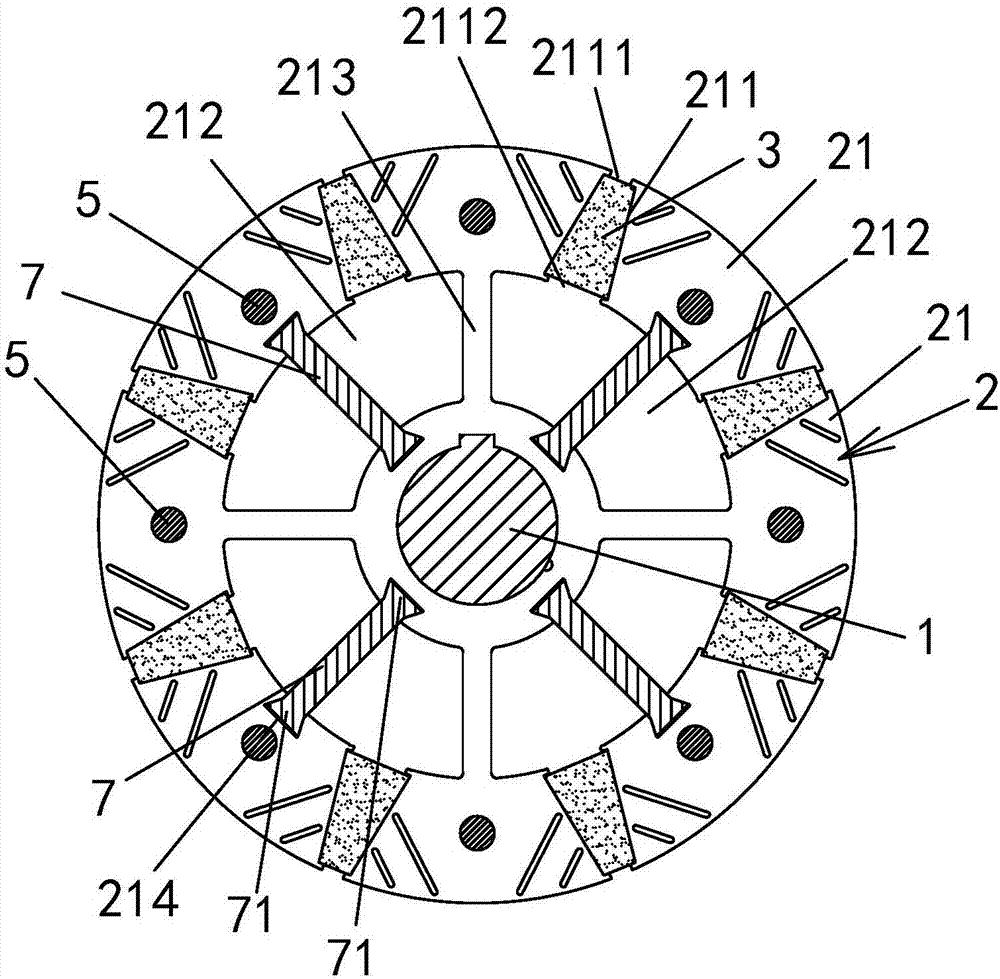

[0021] Embodiment one: see Figure 1 to Figure 3 :

[0022] A permanent magnet motor rotor, including a rotating shaft 1, a rotor core 2 and a permanent magnet 3, the rotor core 2 is stacked by punching sheets 21, see Figure 1 to Figure 3 As shown, the center of each punching piece 21 is provided with a central hole connected to the rotating shaft, and a plurality of magnetic steel slots 211 for accommodating the permanent magnet 3 are arranged on the outer periphery of the punching piece 21 in a rotational symmetry around the center of the rotating shaft 1, and the punching A plurality of air isolation slots 212 are provided on the sheet 21 between the central hole and the magnetic steel slots 211 .

[0023] see Figure 1 to Figure 3 As shown, the magnetic steel groove 211 breaks the fracture opening 2111 toward the air gap side, and the fracture opening 2112 is also interrupted on the side of the air magnetic isolation groove 212 to communicate with the air magnetic isola...

Embodiment 2

[0032] A permanent magnet motor rotor, the only difference from the embodiment is that the magnetic steel groove 211 is closed toward the side of the air gap without interruption, that is, there is no fracture 2111, and the other is the same as the first embodiment. Compared with the prior art, such a design also reduces magnetic flux leakage to a certain extent.

Embodiment 3

[0034] A permanent magnet motor includes a rotor and a stator. The specific structure of the rotor is the same as that described in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com