Cryogenic liquid storage tank with porous medium

A porous medium, low temperature liquid technology, used in gas/liquid distribution and storage, fixed-capacity gas storage tanks, outer walls of container structures, etc. problem, to achieve the effect of large contact thermal resistance, simple implementation method and slowing down the formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

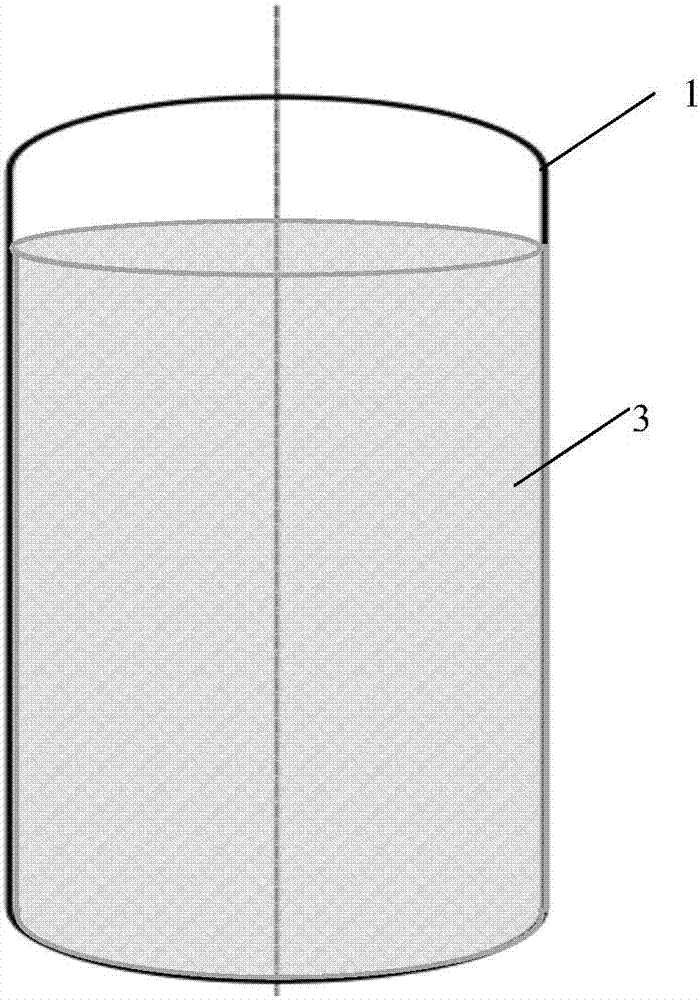

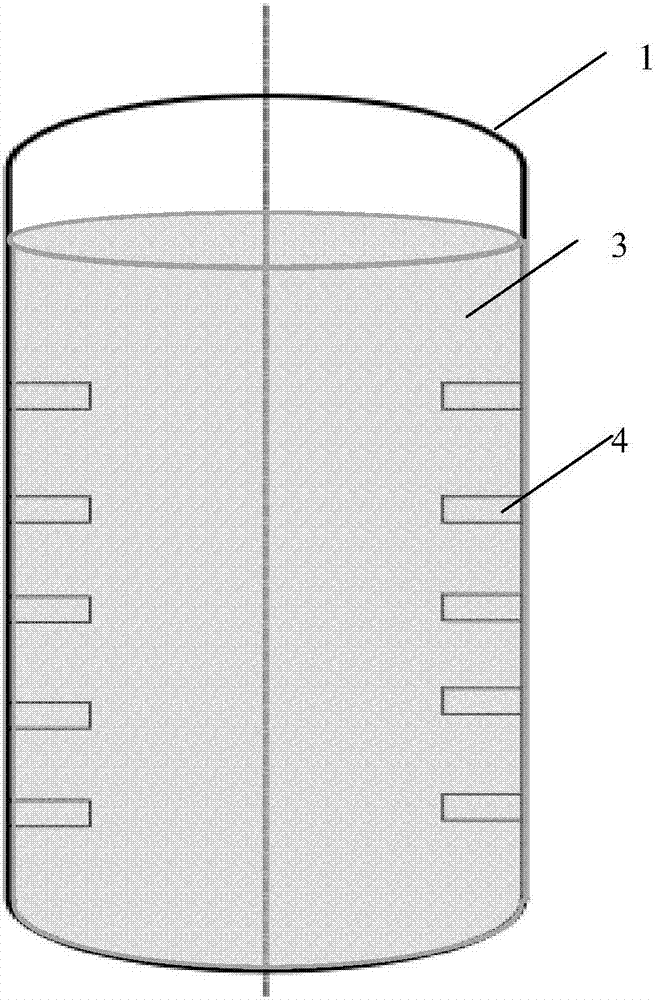

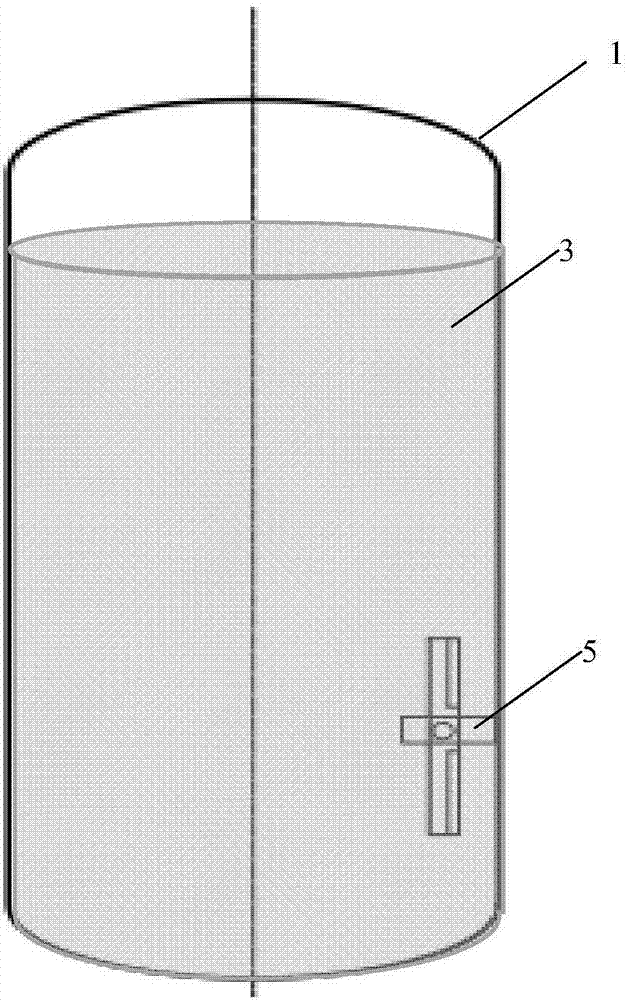

[0030] Such as Figure 1~3 As shown, the prior art cryogenic liquid storage tank has a ribbed structure and a structure with a built-in rotating stirrer to reduce the cryogenic liquid storage tank and eliminate the thermal stratification of the cryogenic liquid.

[0031] figure 1 The cryogenic liquid storage tank includes a cryogenic storage tank body 1 and a filled cryogenic liquid 3. figure 2 In the low-temperature storage tank body 1 is provided with fins 4. image 3 In the low-temperature storage tank body 1 is provided with a rotary agitator 5.

[0032] Such as Figure 4 As shown, the cryogenic liquid storage tank of this embodiment includes: a cryogenic storage tank body 1, a filled cryogenic liquid 3, and a porous medium filler 2.

[0033] In this embodiment, the low-temperature storage tank body 1 is composed of upper and lower elliptical heads and cylindrical cylinders, and the porous medium filler 2 is only arranged in the cryogenic liquid 3, regardless of the head part and...

Embodiment 2

[0037] This embodiment is the same as Embodiment 1 except for the structure of the porous medium filler 2.

[0038] Such as Figure 5 with 6 As shown, the porous medium filler 2 of this embodiment adopts a metal copper wire mesh with a diameter of 0.1 mm, a 20 mesh, and a porosity of 0.94, which is arranged on the inner wall of the low-temperature storage tank 1 in a ring shape.

[0039] The number of porous media filler 2 attached to the wall of the annular structure is 100 pieces, and the ratio of the total thickness of the wire mesh to the diameter of the low temperature storage tank is 1:25.

Embodiment 3

[0041] This embodiment is the same as Embodiment 1 except for the structure of the porous medium filler 2.

[0042] Such as Figure 7 As shown, the porous medium filler 2 of this embodiment uses a common commercially available copper wire mesh with a diameter of 0.1 mm, 20 mesh, and a porosity of 0.94. Metal copper wire mesh is evenly filled with cryogenic liquid 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com