Rotary type hydraulic valve

A hydraulic valve, rotary technology, applied in the field of rotary hydraulic valves, can solve the problems of large volume, uneconomical, enlarged diameter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to further understand the structure, features and functions of the present invention, preferred embodiments are attached herewith and detailed descriptions are as follows in conjunction with the accompanying drawings.

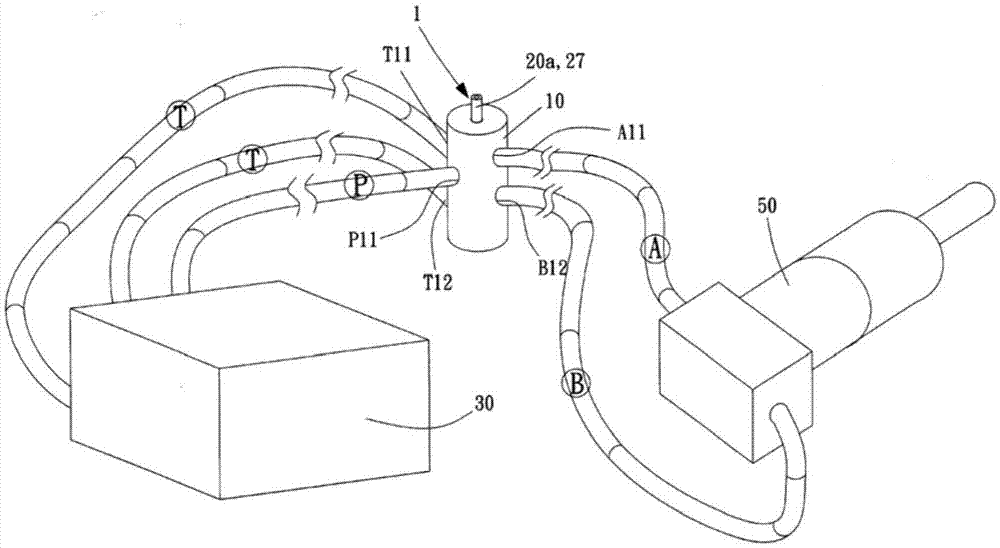

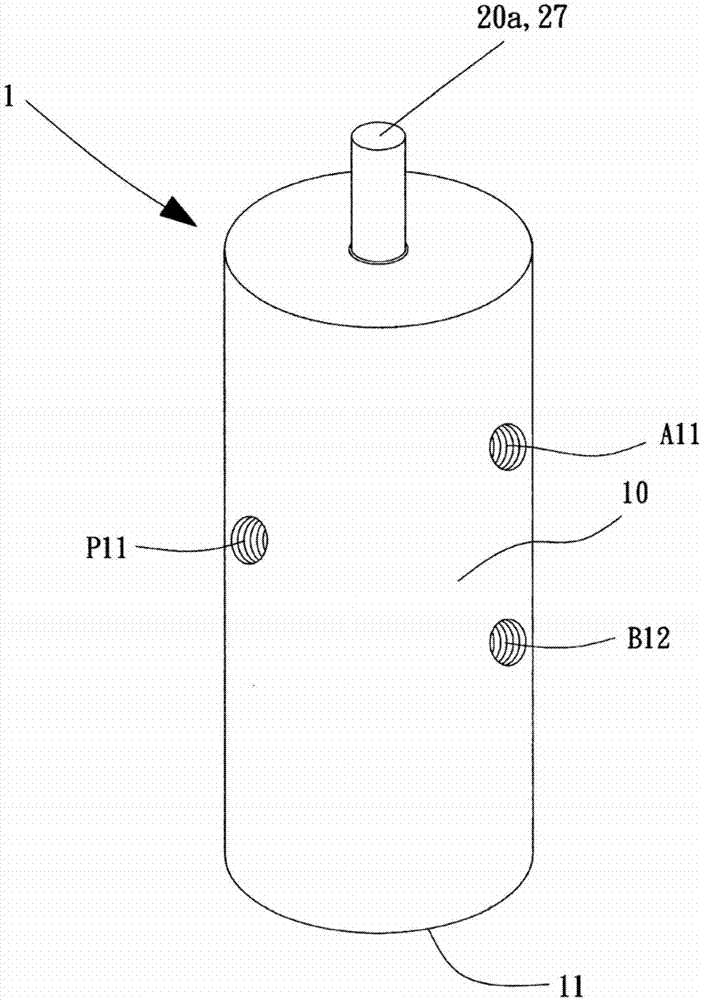

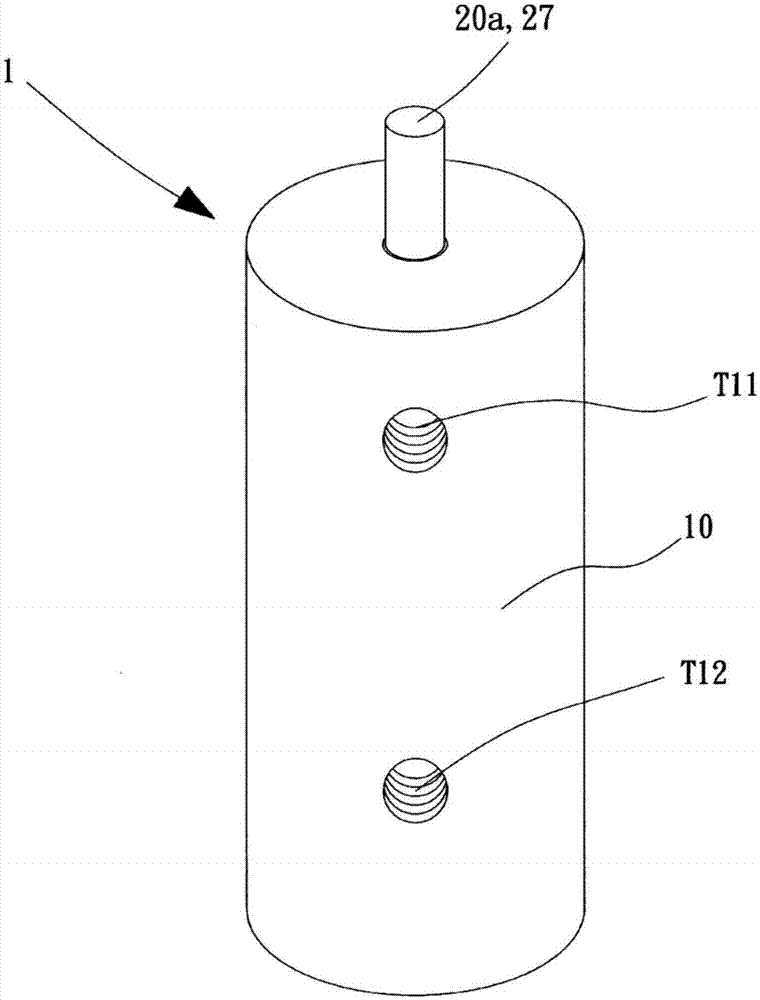

[0056] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 as well as Figure 7 As shown, the rotary hydraulic valve 1 of the present invention mainly includes a valve body 10 with a rotating space 100 inside and a sealed upper part and a valve core 20a with a shaft 20; The oil inlet outer hole P11, the first working outer hole A11, the second working outer hole B12, the first oil return outer hole T11, and the second oil return outer hole T12 of the rotating space 100; wherein, the oil inlet outer hole P11, the second oil return outer hole The first oil return outer hole T11 and the second oil return outer hole T12 are connected to the oil pressure source 30, the first working outer hole A11 and the second working oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com