A kind of environment-friendly rust-removing phosphating agent and its preparation and use method

A kind of derusting and phosphating agent, an environmentally friendly technology, applied in the coating process of metal materials, etc., can solve problems such as unevenness and loose phosphating film, achieve enhanced adhesion, prevent over-corrosion and hydrogen embrittlement, and uniform film formation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

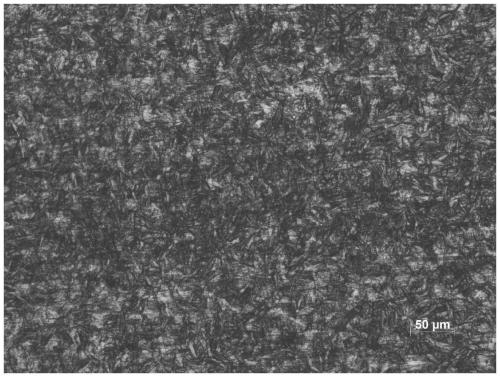

Image

Examples

Embodiment 1

[0038] An environmentally friendly rust removing and phosphating agent whose chemical composition is composed of the following mass percentages:

[0039] Phosphoric acid: 55%;

[0040] Aluminum dihydrogen phosphate: 3%;

[0043] Thiourea: 0.5%;

[0044] Cetylamine: 1.5%

[0045] Sodium secondary alkyl sulfonate: 0.2%;

[0046] Block polyether F68: 0.3%;

[0047] Water: 33.5%.

[0048] The preparation method of the above environmentally friendly rust removing phosphating agent is specifically as follows:

[0049] Take the material according to the chemical composition ratio of the above-mentioned environmentally friendly derusting and phosphating agent, add nitrate, dihydrogen phosphate, compound corrosion inhibitor thiourea and cetylamine into water, stir at room temperature until completely dissolved, and then add phosphoric acid With the surface active agent sodium secondary alkyl sulfonate and block polyether F68, the environment-f...

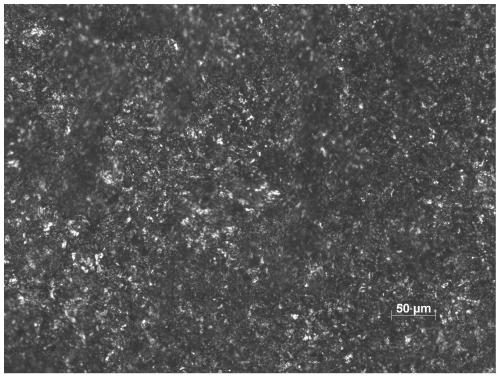

Embodiment 2

[0054] An environmentally friendly rust removing and phosphating agent whose chemical composition is composed of the following mass percentages:

[0055] Phosphoric acid: 45%;

[0056] Manganese dihydrogen phosphate: 2%;

[0057] Zinc dihydrogen phosphate: 4%;

[0058] Zinc nitrate: 0.2%;

[0059] Potassium nitrate: 0.8%;

[0060] Thiourea: 0.3%;

[0061] Cetylamine: 0.3%;

[0062] Urotropine: 0.4%;

[0063] Sodium secondary alkyl sulfonate: 1.5%;

[0064] Block polyether L64: 1.5%;

[0065] Water: 44%.

[0066] The application method of the above environmentally friendly rust removing and phosphating agent in the rust removing and phosphating of steel surface is as follows:

[0067] Treat the steel products to be cleaned with a treatment solution containing 150Kg of environmentally friendly rust removing and phosphating agent per ton of solution. The treatment methods include soaking, brushing and spraying. The treatment temperature is 30°C and the treatment time is 15 minutes.

[0068] After t...

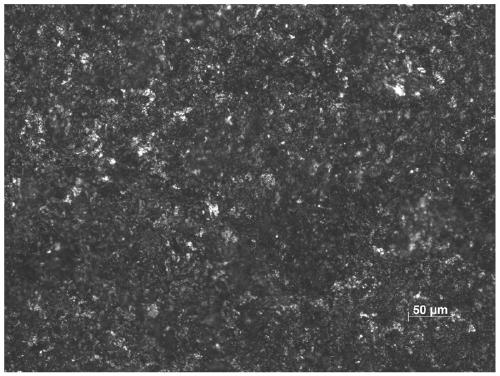

Embodiment 3

[0147] The chemical composition of an environmentally friendly rust removing and phosphating agent is composed of the following mass percentages:

[0148] Phosphoric acid: 35%;

[0149] Potassium dihydrogen phosphate: 10%;

[0150] Potassium nitrate: 10%;

[0151] Cetylamine: 0.1%;

[0152] Urotropine: 0.1%;

[0153] Sodium secondary alkyl sulfonate: 0.5%;

[0154] Block polyether L61: 0.5%;

[0155] Block polyether F38: 0.5%;

[0156] Water: 43.3%.

[0157] The application method of the above environmentally friendly rust removing and phosphating agent in the rust removing and phosphating of steel surface is as follows:

[0158] Treat the steel products to be cleaned with a treatment solution containing 150Kg of environmentally friendly rust removing and phosphating agent per ton of solution. The treatment methods include immersion, brushing and spraying. The treatment temperature is 10°C and the treatment time is 40 minutes.

[0159] After testing, the above-mentioned derusting and phosphati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com