Method for preparing saffron crocus extract for cigarette from immobilized beta-glucosidase

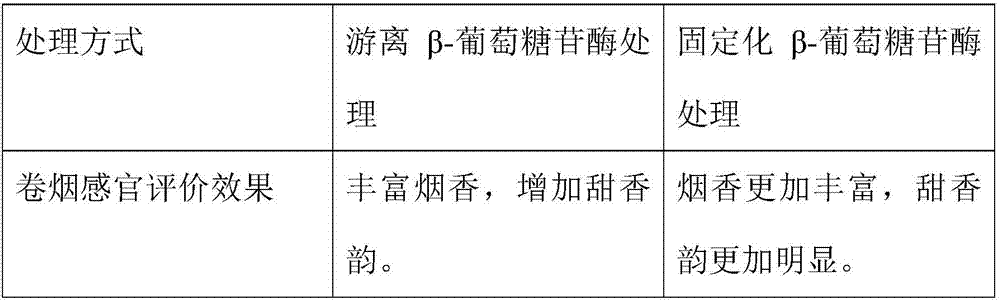

A technology of saffron extract and glucosidase, applied in biochemical equipment and methods, preparation of tobacco, immobilization on/in organic carriers, etc., can solve problems such as unreported saffron extract for tobacco, and achieve aroma Enrich, increase sweet aroma, increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Get dried saffron flowers, add water of 5 times its weight, microwave extraction twice, each time for 1 hour, filter the extract after cooling, collect the filtrate to obtain the saffron extract;

[0019] (2) Dissolve 0.2g of solid β-glucosidase in 1mL of citric acid buffer (0.1mol / L, pH4.5), add 18mL of sodium alginate solution with a mass concentration of 2%, stir well, and then add 26mL The mass concentration was 2% (W / V) calcium chloride solution, embedded at 4°C for 1.5 h, and washed with buffer solution to obtain sodium alginate-immobilized enzyme with a loading capacity of 15 U / g.

[0020] (3) Get the immobilized β-glucosidase to process the saffron extract, the solid dosage of the immobilized β-glucosidase is 0.5g / L, the pH value of the enzyme treatment is 3~4, the enzyme treatment temperature is 35°C, and the enzyme treatment time is 30h, After the treatment is completed, settle at 3°C for 36 hours;

[0021] (4) the extract after the enzyme treatment is ...

Embodiment 2

[0023] (1) Get dried saffron flowers, add water of 15 times its weight, microwave extraction twice, each time for 3 hours, filter the extract after cooling, collect the filtrate to obtain the saffron extract;

[0024] (2) Dissolve 0.1g of solid β-glucosidase in 1mL of citric acid buffer (0.1mol / L, pH4.5), add 15mL of sodium alginate solution with a mass concentration of 2%, stir well, and then add 20mL The mass concentration was 2% (W / V) calcium chloride solution, embedded at 4°C for 1 hour, and washed with buffer solution to obtain sodium alginate-immobilized enzyme with a loading capacity of 10 U / g.

[0025] (3) Get immobilized β-glucosidase to process saffron extract, immobilized β-glucosidase solid dosage 5g / L, the pH value of enzyme treatment 5~6, enzyme treatment temperature 30 ℃, enzyme treatment time 15h, process After completion, settle at 3°C for 40 hours;

[0026] (4) the extract after the enzyme treatment is filtered with filter paper to remove large particles o...

Embodiment 3

[0028] (1) Get dried saffron flowers, add water of 10 times its weight, microwave extraction twice, each 2 hours, filter the extract after cooling, collect the filtrate to obtain the saffron extract;

[0029] (2) Dissolve 0.3g of solid β-glucosidase in 1mL of citric acid buffer (0.1mol / L, pH4.5), add 20mL of sodium alginate solution with a mass concentration of 2%, stir well, and then add 30mL The mass concentration was 2% (W / V) calcium chloride solution, embedded at 4°C for 3 hours, and washed with buffer solution to obtain sodium alginate immobilized enzyme with a loading capacity of 20 U / g.

[0030] (3) Get the immobilized β-glucosidase to process the saffron extract, the solid dosage of the immobilized β-glucosidase is 2g / L, the pH value of the enzyme treatment is 6~7, the enzyme treatment temperature is 40°C, and the enzyme treatment time is 5h. After completion, settle at 3°C for 48 hours;

[0031] (4) the extract after the enzyme treatment is filtered with filter pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com