Method for preparing nitrogen-doped porous biochar by employing molten salt-assisted high-temperature carbonization method

A high-temperature carbonization, molten salt technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of long-residue pesticide detection rate, difficult degradation of pesticides, etc., to enhance Lewis alkalinity, promote specific adsorption, large The effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

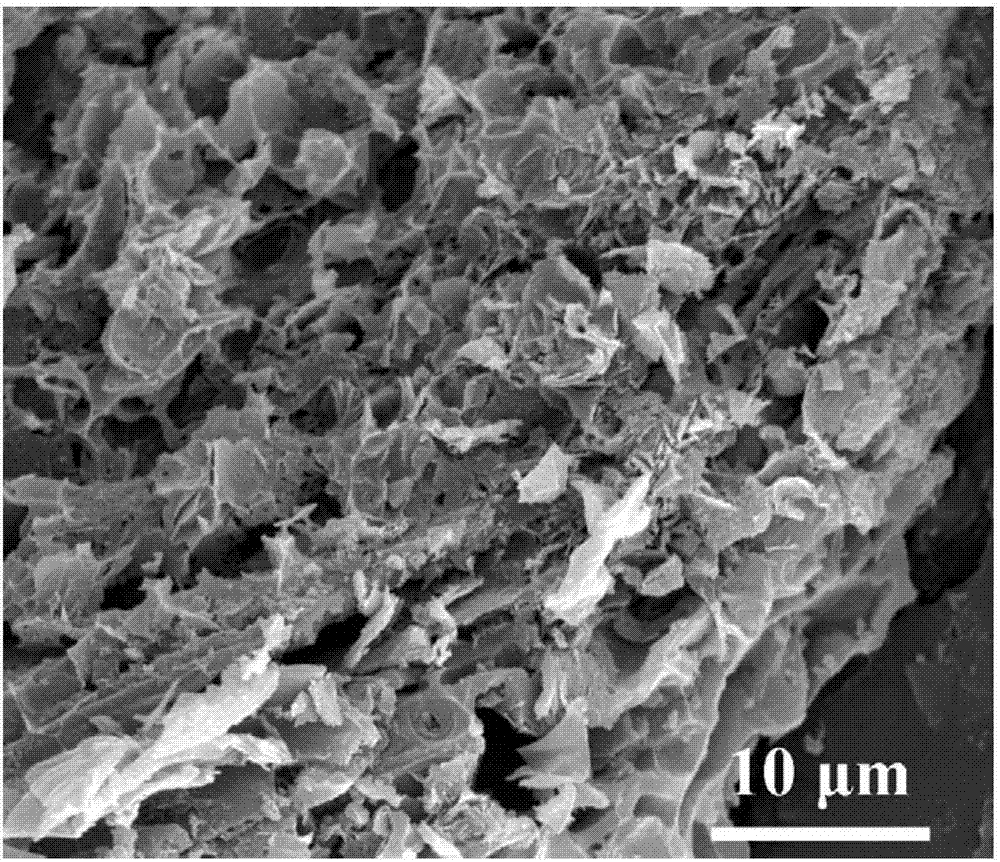

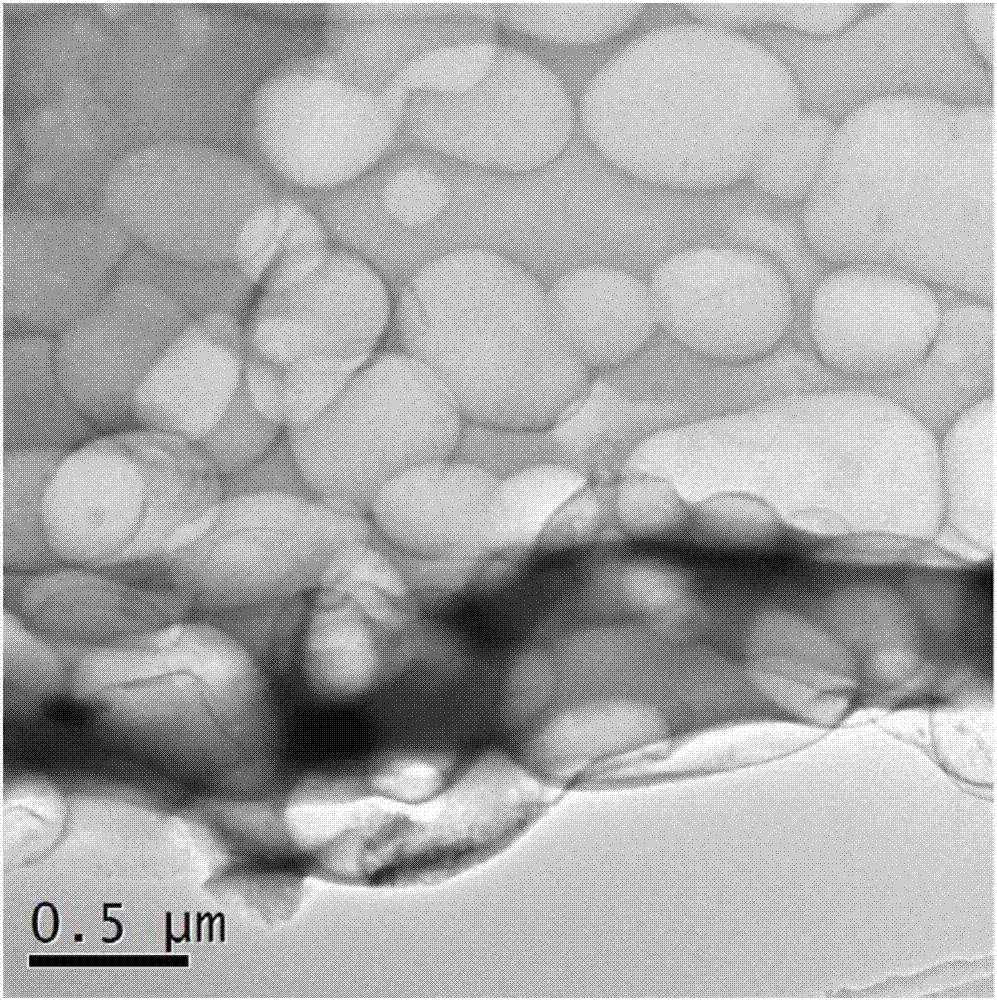

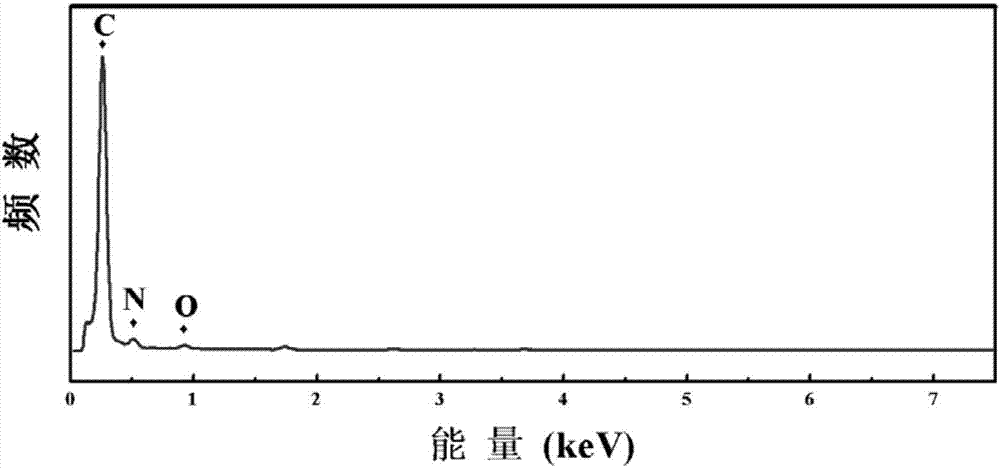

[0030] Embodiment 1: This embodiment is a method for preparing nitrogen-doped porous biochar by molten salt-assisted high-temperature carbonization, which is completed according to the following steps:

[0031] 1. Cleaning:

[0032] Use distilled water to wash the waste biomass 3 to 5 times, then dry it in a constant temperature drying oven at a temperature of 60°C to 100°C for 2h to 8h, then crush the waste biomass and sieve to obtain biomass powder;

[0033] 2. Preparation of biochar:

[0034] Mix the biomass powder with the low-melting-point molten salt containing nitrogen atoms evenly to obtain a mixture; then put the mixture into a vacuum tube furnace under the protection of an inert gas, and then set the vacuum tube furnace at a temperature of 5°C / min to 15°C / min The heating rate is raised to 650°C-1000°C, and then heated at a temperature of 650°C-1000°C for 2h-6h, and finally the vacuum tube furnace is naturally cooled to room temperature to obtain the reaction product...

specific Embodiment approach 2

[0045] Embodiment 2: This embodiment differs from Embodiment 1 in that the waste biomass described in step 1 is straw, rice husk or livestock manure. Others are the same as the first embodiment.

specific Embodiment approach 3

[0046] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the particle size of the biomass powder in step 1 is 100 mesh to 300 mesh. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com