Rotary pressurizing fixation steel plate for posterior cruciate ligament avulsion fracture

A technique for avulsing fractures and fixing steel plates, which is applied in the direction of fixers, outer plates, and internal bone synthesis. It can solve the problems of no medical devices and methods for loose knots, reduced tension, and difficulty in fully tensioning, etc., to meet Requirements for precision medicine and minimally invasive surgery, prevention of tension reduction, good self-locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

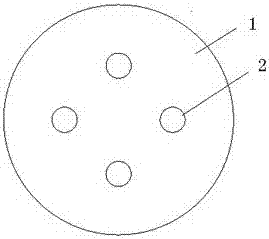

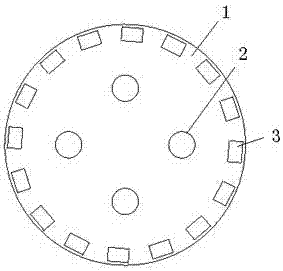

[0017] Shown in the figure, the present invention is a circular steel plate 1, the diameter of the steel plate 1 is 10-12mm, and the thickness is 1-2mm. The steel plate 1 in one embodiment of the present invention has a diameter of 10 mm and a thickness of 1.5 mm.

[0018] The figure shows that there are four circular holes 2 on the surface of the circular steel plate 1, the four circular holes 2 are evenly distributed on the surface of the steel plate 1, and the centers of the four circular holes 2 are equal to the center of the circular steel plate 1. The line connecting the centers of the two circular holes 2 is perpendicular to the connecting line between the centers of the other two circular holes 2 . The two diagonal round holes 2 are used to pass the pulling wire, and the other two diagonal round holes 2 are used to rotate the steel plate 1 with a tool.

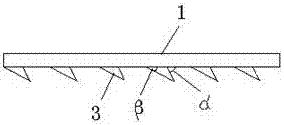

[0019] As shown in the figure, there is a circle of ratchets 3 along the edge of the steel plate 1 on one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com