Commodity bar code with hidden variable data and formation method of commodity bar code

A commodity barcode and data technology, which is applied in the field of commodity barcodes with implicit variable data and its formation, can solve the problems of being unable to scan and recognize two-dimensional codes through upgraded software, and unable to recognize variable data of two-dimensional codes of commodity serial numbers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

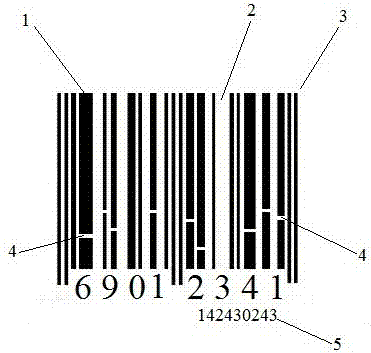

[0081] figure 1 , Figure 15 As shown, the standard size of the current commodity barcode, that is, the one-dimensional barcode (3) is 37.29mm×26.26mm, and the magnification ratio is 0.9-2.0. When the printing area allows, you can choose a one-dimensional barcode ⑶ with a ratio of 1.0 or more.

[0082] In order to make the commodity barcode described in the national standard GB12904-2003, that is, a one-dimensional barcode shared by tens of thousands of products (3)—fixed information, it can also imply logistics codes, lottery codes, traceability codes, etc. that are unique, Variable data unique to each product (5)——variable information. like figure 1 As shown, some breakpoints (4) representing variable data (5) can be printed on some bars (1) or bar spaces (2) in the one-dimensional barcode (3) according to some custom rules.

[0083] like figure 1 As shown, the bar (1) of the one-dimensional barcode (3) is divided into 14 equal parts along the height direction, arrang...

Embodiment 2

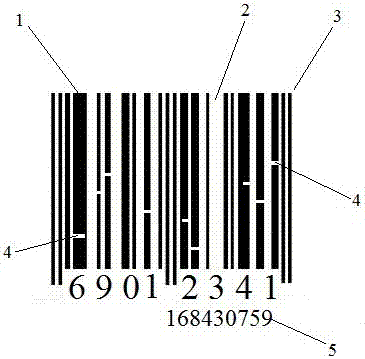

[0092] like figure 2 As shown, all the breakpoints (4) are printed in the lower area of the one-dimensional barcode (3), accounting for less than 67% of the area of the one-dimensional barcode (3). The shortcoming of designing like this is: more than 67% of the one-dimensional barcode (3) area has been damaged, which is unfavorable for reducing the misjudgment rate of one-dimensional barcode (3) identification.

[0093] like figure 2 As shown, some of the bars (1) in the one-dimensional barcode (3) look thicker and some seem thinner. The thick bar ⑴ is actually formed by multiple thin bars ⑴ together, and a single thin bar ⑴ is a standard bar ⑴ module. When a narrow breakpoint (4) is printed on the thick bar (1), the breakpoint (4) looks like a gap.

[0094] The remaining steps of this embodiment are the same as those in Embodiment 1.

Embodiment 3

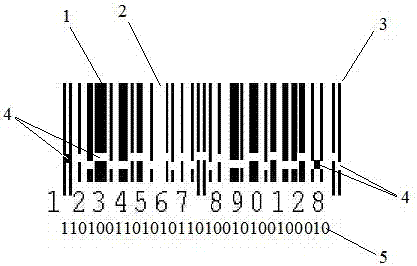

[0096] like image 3 As shown, all breakpoints (4) are all printed on a very narrow area on the one-dimensional barcode (3), accounting for less than 15% of the area of the one-dimensional barcode (3). The advantage of designing like this is: more than 85% of the one-dimensional barcode (3) area is intact, helps to reduce the misjudgment rate of one-dimensional barcode (3) recognition. The disadvantage of this design is: the variable data (5) contained in the breakpoint (4) is slow and difficult to identify.

[0097] In this embodiment image 3 In the above, the bars ⑴ and bar space ⑵ of the one-dimensional barcode ⑶ are divided into 14 equal parts along the height direction, arranged from bottom to top, the 1st-2nd equal parts are used as the start symbol, and the 13th-14th equal parts are used as the end character, the 3rd and 4th equal parts represent the 0th position and the 1st position respectively.

[0098] like image 3 As shown, all 30 bars (1) and bars (2) of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com