Carbon steel pipeline CO2 solution corrosion rate prediction method based on computational fluid mechanics

A technology of computational fluid dynamics and corrosion rate, applied in calculation, computer-aided design, design optimization/simulation, etc., can solve problems such as incapable coupling analysis, save time, manpower and material costs, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

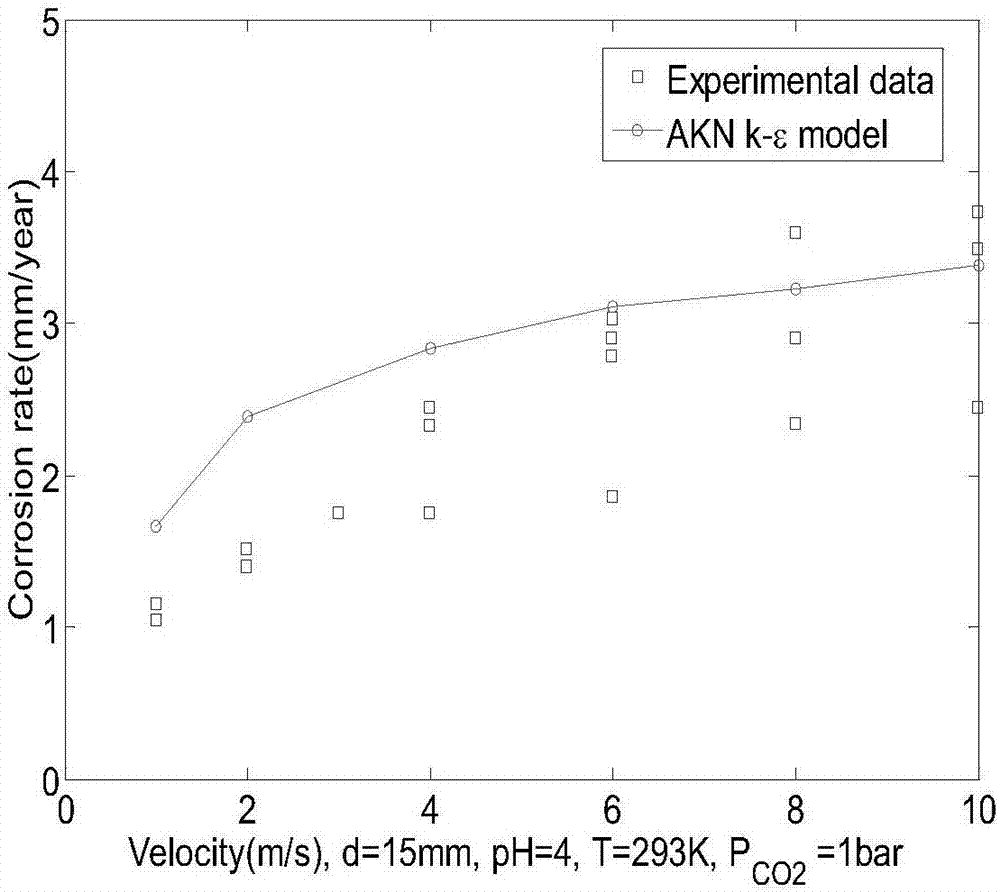

[0052] CO in a carbon steel straight pipe with a diameter of 15mm 2 The corrosion rate prediction of aqueous solution is taken as an example to illustrate the calculation process. The diameter of carbon steel pipe is 15mm, the water flow velocity changes within 1-10m / s, the flow in the pipe is fully developed, the pH of the solution is 4, the water temperature is 20℃, CO 2 Gas partial pressure is 1 standard atmospheric pressure, now utilize the method of the present invention to CO under flow condition 2 Aqueous solution corrosion rate prediction.

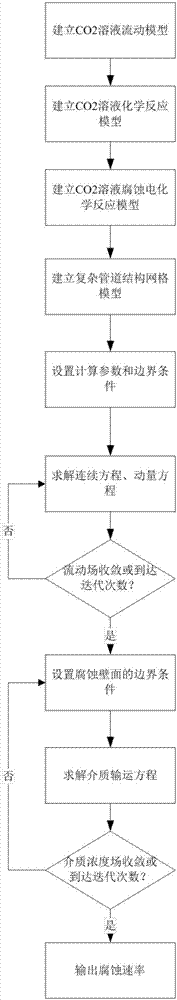

[0053] refer to figure 1 , based on computational fluid dynamics for carbon steel pipeline CO 2 Solution corrosion rate prediction method, comprising the following steps:

[0054] 1) CO 2 Aqueous solution flow model establishment:

[0055] will contain CO 2 The aqueous solution is regarded as an inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com