Metal detection apparatus, testing device and method for optimising a metal detection apparatus

A technology for testing devices and equipment, which is applied in the directions of measuring devices, utilization of re-radiation, and re-radiation of sound waves, which can solve the problems of optimizing metal detection equipment and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

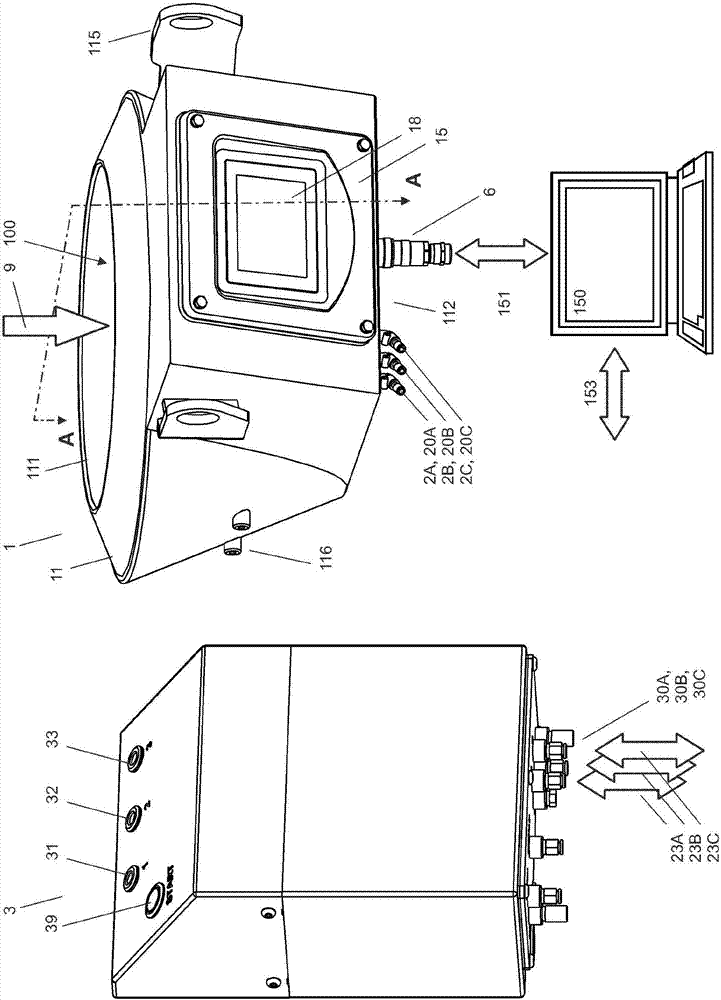

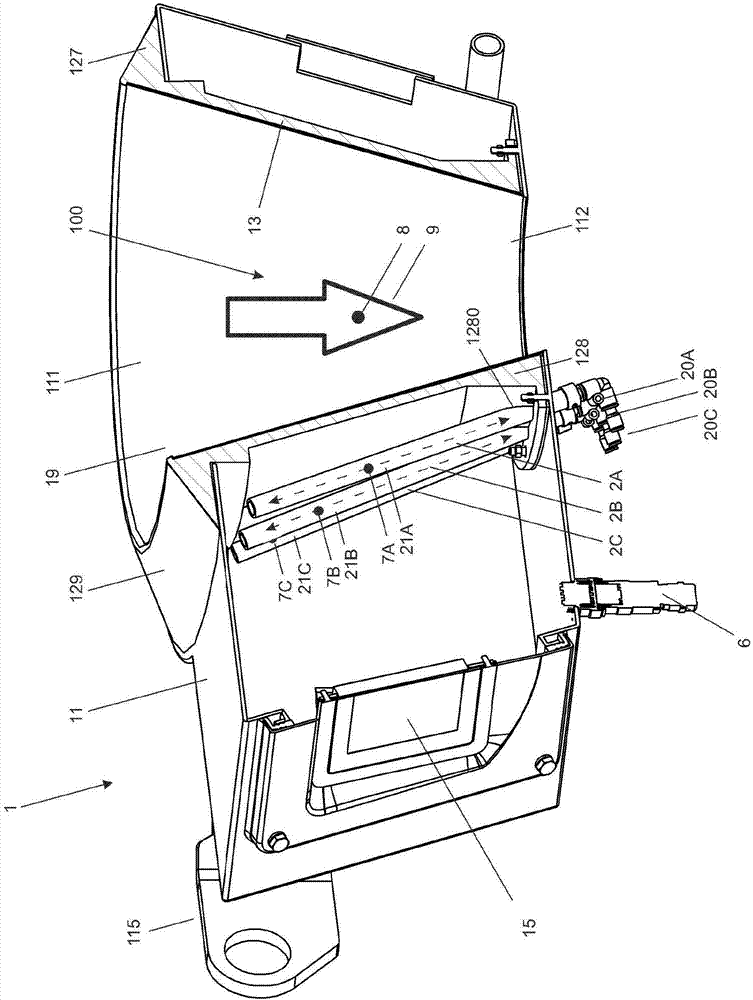

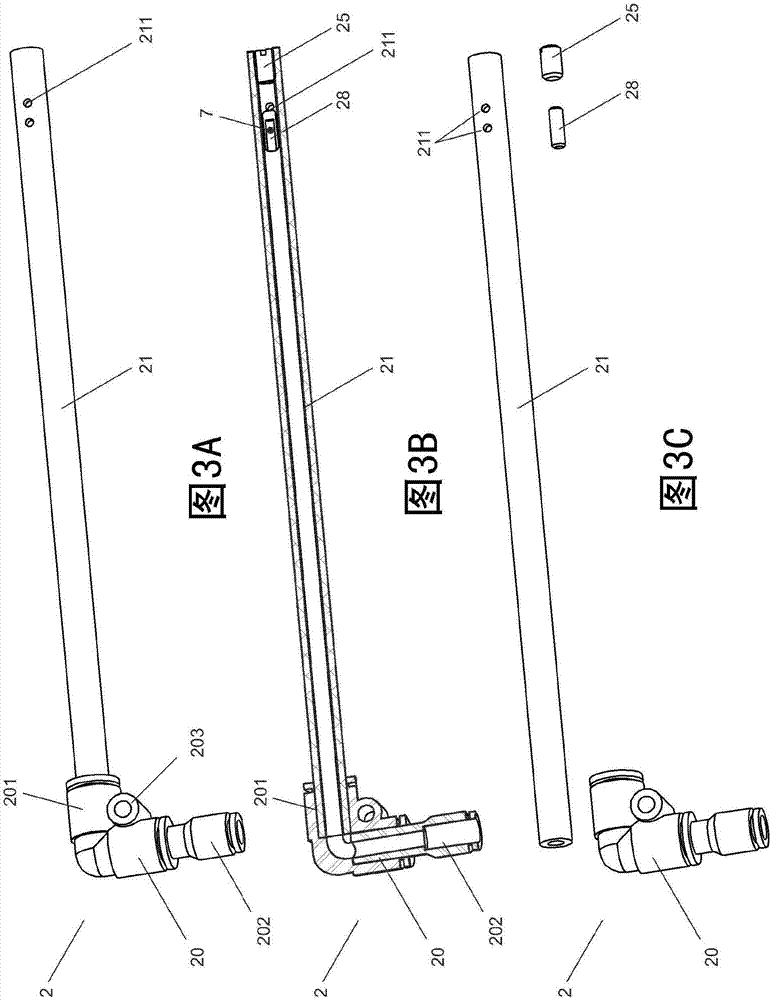

[0053] figure 1 The metal detection device 1 of the invention is shown equipped with three test devices 2A, 2B, 2C connected to the pneumatic control device 3 as symbolically indicated by the arrows.

[0054] The metal detection device 1 is designed to detect metal-contaminated products in vertical packaging applications, ie for inspecting products in flight before insertion into a sealed package. The device is designed with a minimum height to allow it to be installed, for example, in a confined space between the scale and the bag making machine.

[0055] The metal detection device 1 comprises a housing 11 having an inlet aperture 111 and an outlet aperture 112 which define inside the housing 11 a travel path along which the object 9 under inspection can move through the detection zone 100 . In order to mount the metal detection device 1 , the housing 11 is equipped with mounting means such as a mounting flange 115 and a mounting hole 116 .

[0056] The metal detection dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com