Oil-electric hybrid continuously variable transmission device

A technology of infinitely variable speed and hybrid motion, which is applied to transmission devices, belts/chains/gears, mechanical equipment, etc. It can solve the problems of not being able to achieve speed change in time, and achieve the effect of smooth speed change and no sense of frustration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

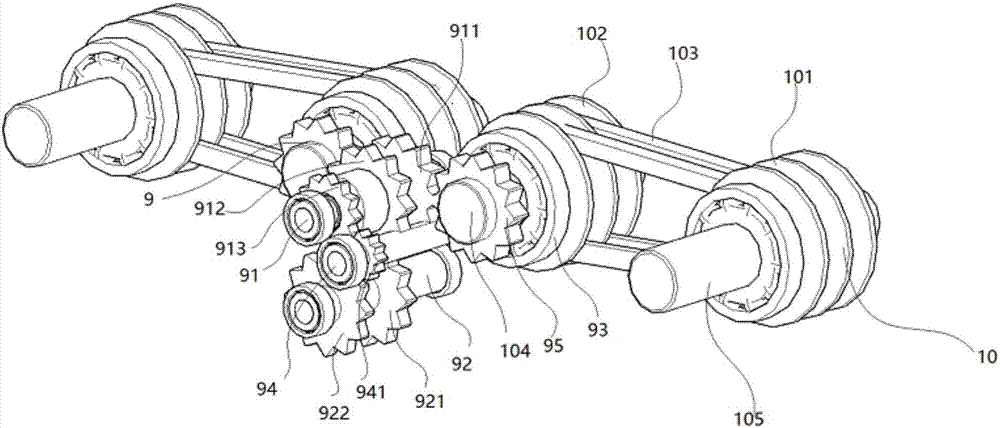

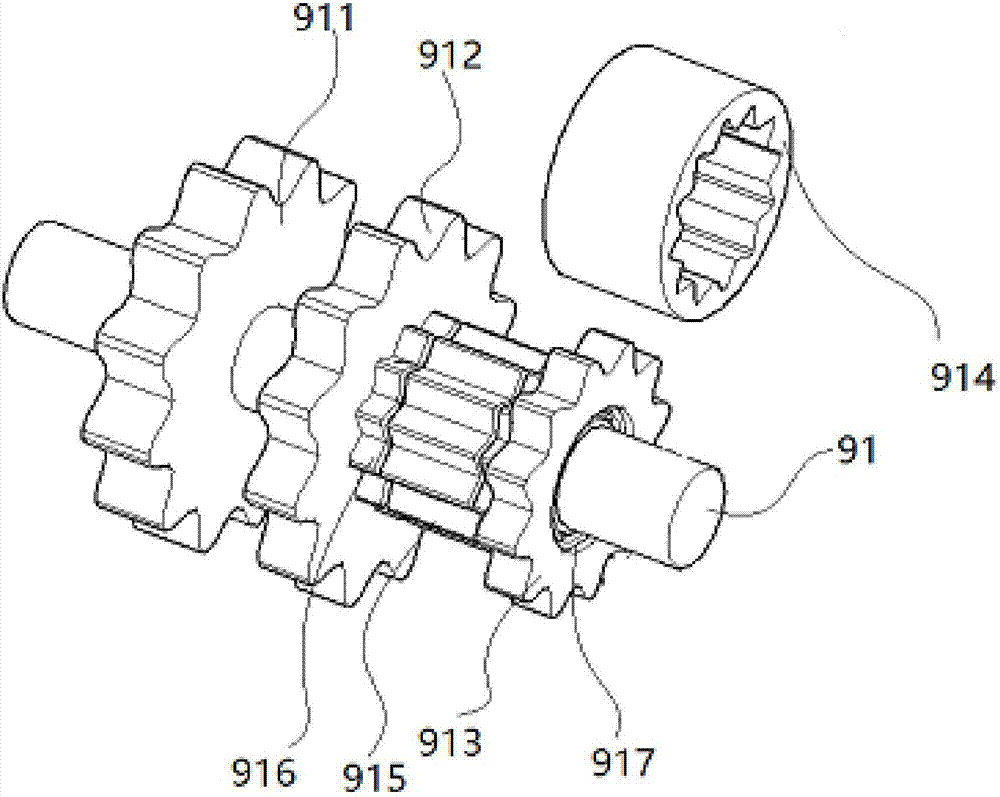

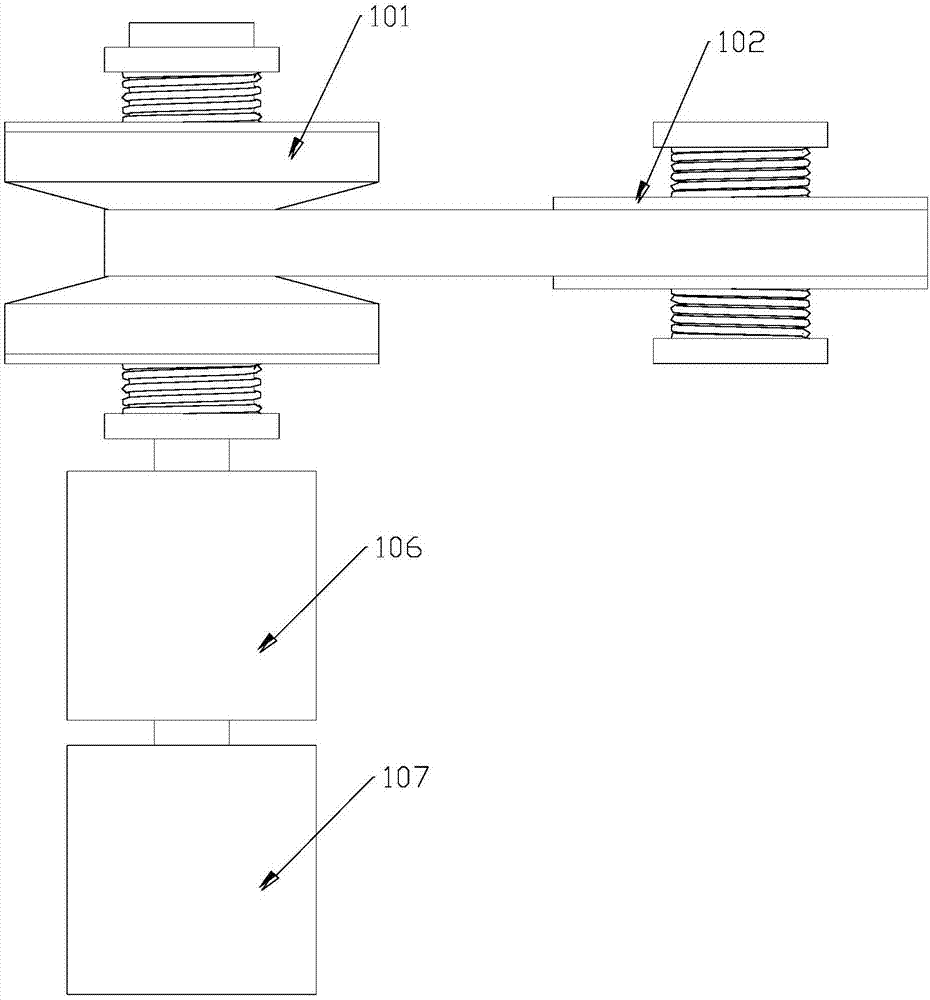

[0020] An oil-electric hybrid continuously variable transmission device, comprising a transmission mechanism 10 connected to an engine; a transmission mechanism 9 connected to an actuator, the transmission mechanism 9 and the transmission mechanism 10 are meshed through gears, and the transmission mechanism 10 includes A belt pulley with adjustable wheel groove size is installed on the driving wheel shaft 105 and the pulley shaft 104. , the output end of the driving wheel 101 is installed with a generator 106 and a motor 107 in sequence. In the present invention, by setting the combined pulley, the pulley can change the size of the pulley groove at different rotating speeds, and change the transmission ratio between the two pulleys to realize the purpose of adjusting the rotating speed of the output shaft.

[0021] Further, in ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com