Motor fan pump for vacuum cleaner

A technology of vacuum cleaners and air pumps, which is applied in the direction of vacuum cleaners, machines/engines, pumps, etc., which can solve the problems of high noise of vacuum cleaners and achieve the effect of ensuring quiet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

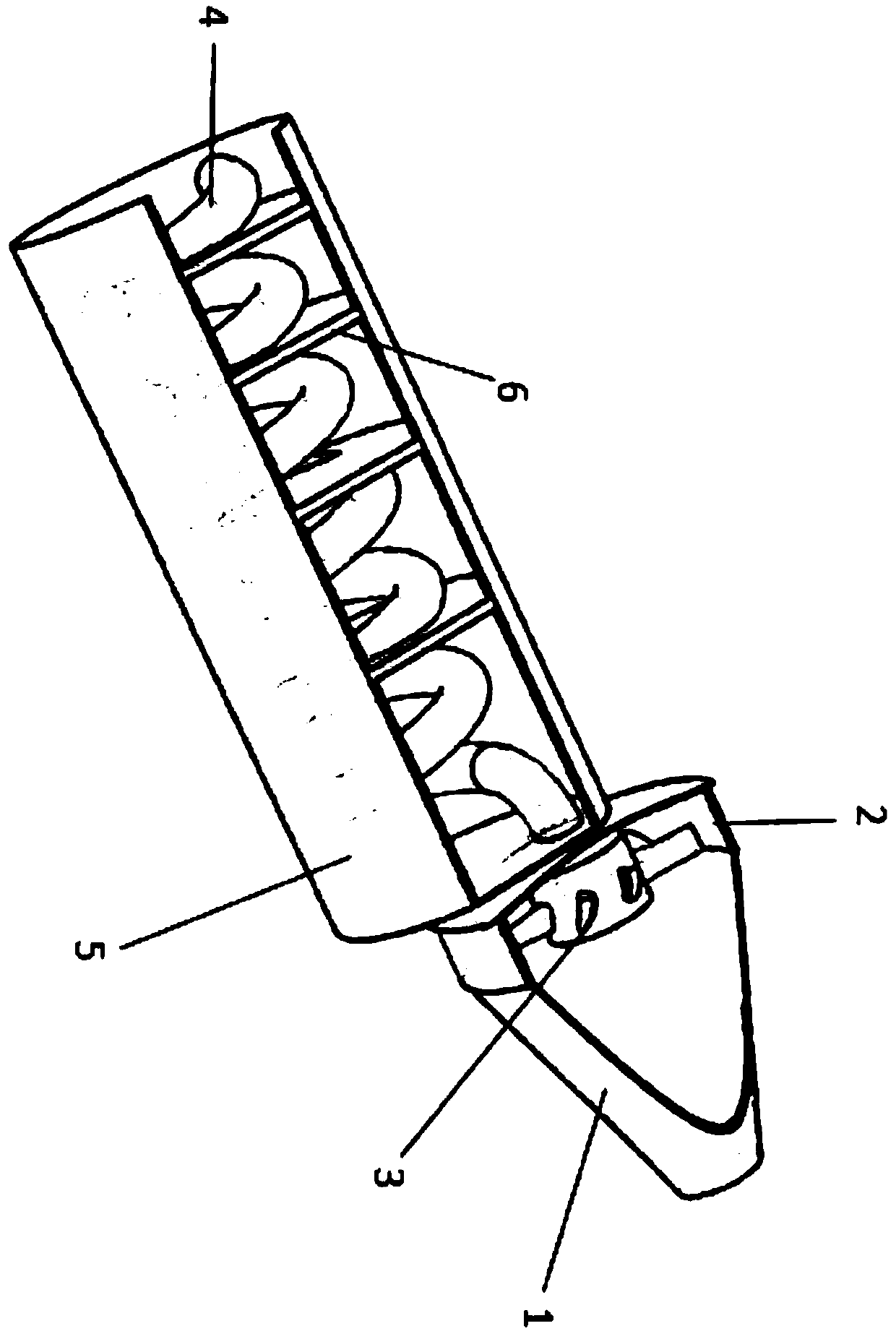

[0032] Such as figure 1 As shown, a motor air pump for a vacuum cleaner includes: an air intake pipe 1, which is a circular frustum shell structure, the top of the air intake pipe 1 is provided with a first opening, and the bottom of the air intake pipe 1 is provided with a second opening Fan housing 2, which is a cylindrical shell structure, the top opening of the fan housing 2 is airtightly connected with the second opening of the air intake duct 1, and the bottom of the fan housing 2 is provided with a third opening; the fan 3 is installed on In the blower cover 2, the blower fan 3 discharges air toward the third opening, and the blower fan 3 is connected with the inner wall of the blower blower cover 2 through a fixing frame; The air duct 4 is provided with a fully covered exhaust hood 5, the first end of the exhaust hood 5 is closed, the first end of the exhaust duct 4 runs through the first end of the exhaust hood 5 and is connected to the fan. The third opening of the ...

Embodiment 2

[0042] The wall of the exhaust pipe 4 in the buffer chamber where the second end of the exhaust cover 5 is located does not have the through hole.

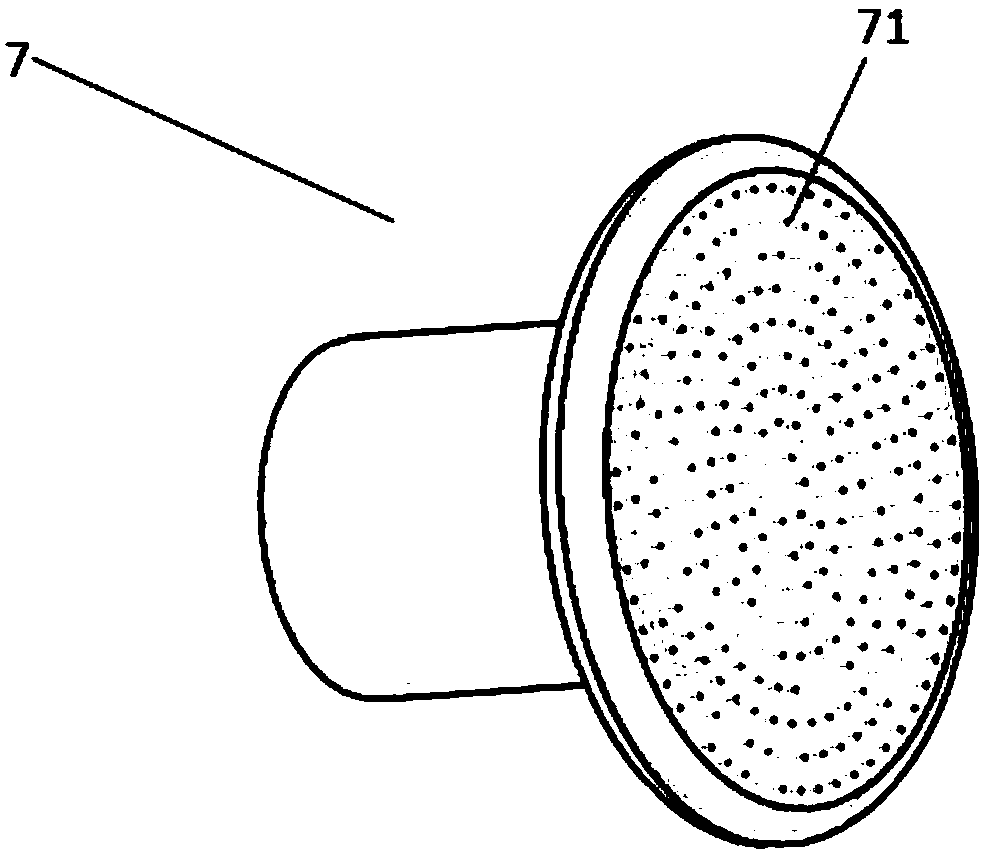

[0043] Such as figure 2 As shown, the exhaust pipe 4 also includes a small hole muffler 7, the air inlet of the small hole muffler 7 is connected through the tail of the exhaust pipe 4, and the center distance between adjacent small holes 71 on the small hole muffler It is more than 5 times the diameter of the small hole 71. The buffer cavity where the second end of the exhaust cover 5 is located is the tail end buffer cavity through which the airflow finally flows. Will be completely discharged from the tail of the exhaust pipe 4. By connecting a small hole muffler 7 at the tail of the exhaust pipe 4, the mid-low frequency noise retained in the airflow is converted into a high-frequency sound inaudible to the human ear, thereby achieving the purpose of noise reduction. When the distance between the small holes 71 is large eno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com