Local cooling device and method for mine

A local cooling and mine technology, applied in the direction of safety devices, mine/tunnel ventilation, mining equipment, etc., can solve the problems of large cooling energy loss, large energy consumption, and increased refrigeration system load, so as to reduce economic losses and accidents, The effect of reducing mining costs and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

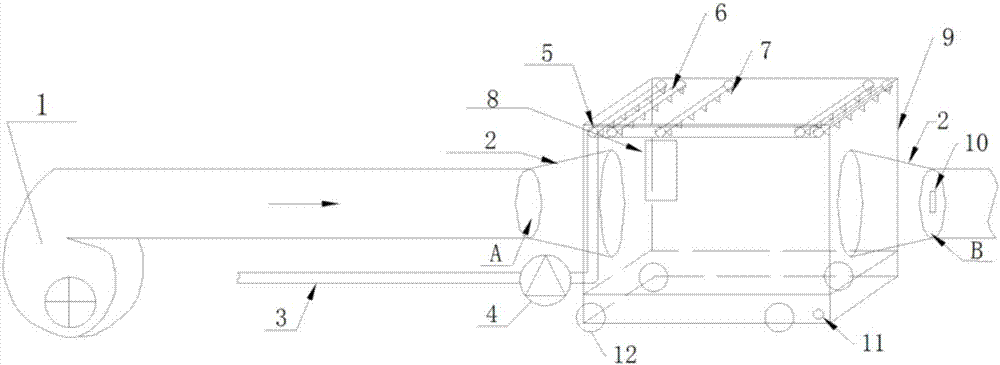

[0039] A mine local cooling device, the structure diagram is as follows figure 1 As shown, it includes a local fan 1, a detachable air cylinder 2, a water inlet pipe 3, a high-pressure water pump 4, and a cooling chamber 9. The top of the cooling chamber 9 is provided with a spray device, and the cooling chamber 9 is provided with an air inlet A and an air outlet B. :

[0040] The spraying device includes a water guide pipe 6 and an atomizing nozzle 7, and the atomizing nozzle 7 is arranged on the water guide pipe 6;

[0041] The local fan 1 is connected to the air inlet A through the detachable air cylinder 2, and the air outlet B is connected to the excavation working face through the detachable air cylinder 2. A temperature tester 10 is installed at the air outlet B to measure the cooling temperature at the air outlet B. Air flow temperature; wherein, the detachable air duct 2 connected to the excavation face has a length of 90m and a diameter of 1m;

[0042] The water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com