Rotary vane type viscous damper

A viscous damper and rotary vane technology, which is applied in the direction of protective buildings/shelters, building components, building types, etc., can solve problems such as insufficient spring stiffness, failure to reach, and vacuum generated by the oil cylinder, etc., to improve vibration The effect of controlling efficiency, improving anti-seismic effect, and flexible layout position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

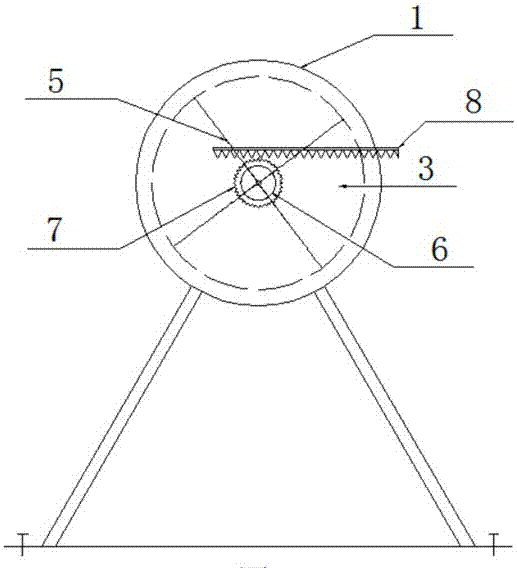

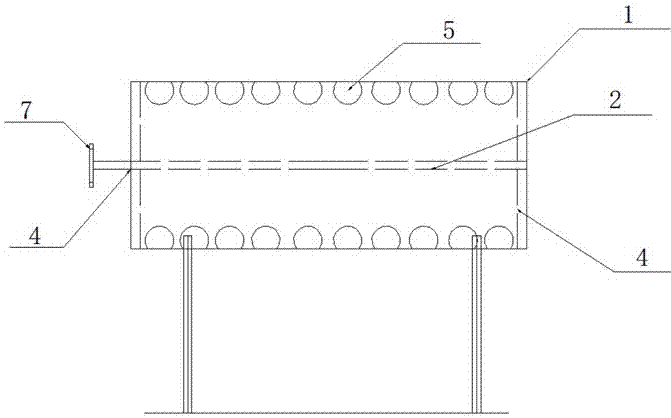

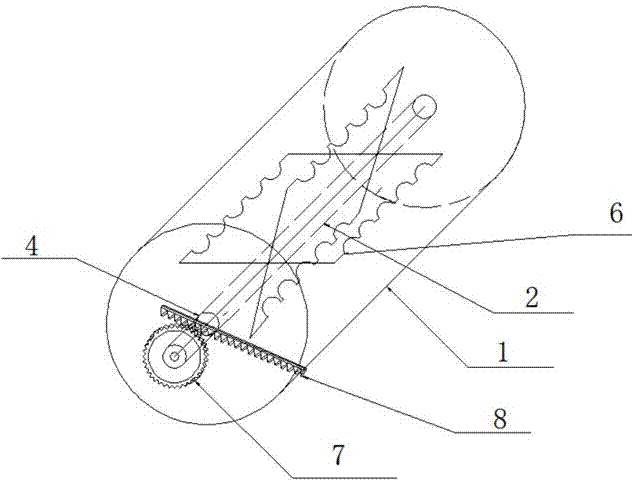

[0022] Embodiment 1: as figure 1 Shown is an embodiment of a rotary vane viscous damper of the present invention, which mainly includes a gear transmission amplifier and a rotary vane damper. The gear transmission amplification device consists of a rotating shaft 2, a damper connector 4, a transmission gear 7 and an input rod 8, and the rotary vane viscous damper is composed of a cylindrical box 1, a viscous liquid 3, a rotating blade 5, and a flow hole 6 .

[0023] Cylindrical box 1 has a radius of 200mm and a length of 800mm, and contains a viscous liquid 3 inside; the rotating shaft 2 has a radius of 25mm and a length of 900mm, and is installed on the box 1 through a leading port; the rotating shaft 2 is located in the box The part inside the body 1 can be installed with one or more rotating blades 5, the length of the rotating blade 5 is 800mm, the width is 200mm, and a circle of circular flow holes 6 is opened on the edge; Connect transmission gear 7, its radius is 500m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com