Method for preparing titanium dioxide slurry

A titanium dioxide slurry, titanium dioxide technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment and other directions, can solve the serious thixotropy of titanium dioxide filter cake, the solid-liquid separation method needs to be improved, and the sodium chloride cannot be separated. and other problems, to achieve the effect of improving efficiency and desalination effect, promoting removal, and thorough solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

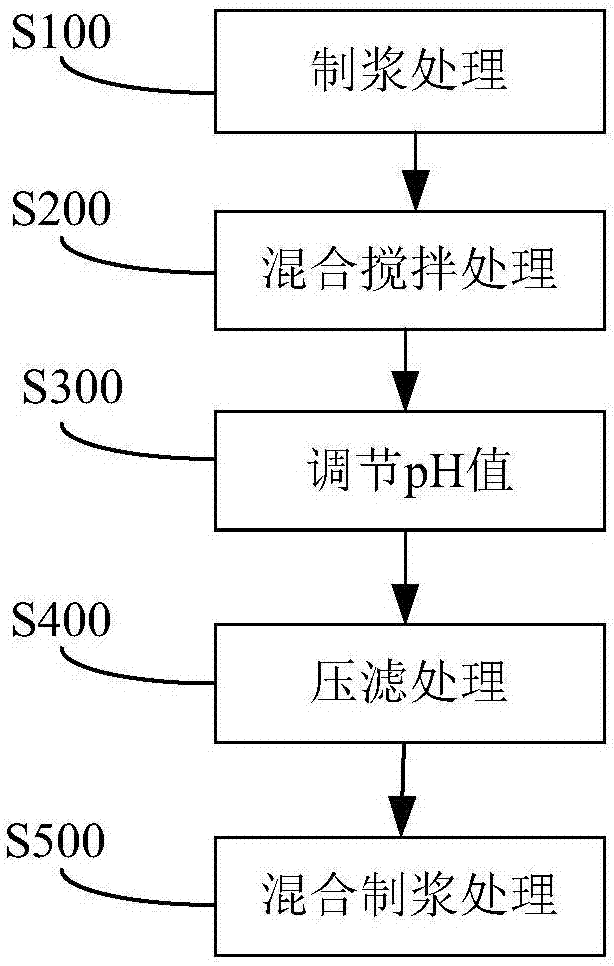

Method used

Image

Examples

Embodiment 1

[0064] Utilize the method for the embodiment of the invention to TiCl 4 The titanium dioxide particles obtained by oxidation reaction are processed to prepare titanium dioxide slurry, the specific method is as follows:

[0065] (1) TiCl 4 The titanium dioxide particles obtained by the oxidation reaction were added to desalted water to prepare a slurry with a concentration of 450g / L. The pH value of the slurry was 3.08 and the viscosity was 47.2mPa·s;

[0066] (2) get 2L and add the aluminum sulfate solution that mass fraction is 0.2% of titanium dioxide content (its solution concentration is with Al 2 o 3 Calculated as 100g / L), the pH value of the slurry after adding is 2.41, and the viscosity is 45.3mPa·s;

[0067] (3) Add sodium hydroxide to the slurry obtained in step (2) to adjust the pH to 4.50, and the adjusted viscosity is 80.6mPa·s;

[0068] (4) The slurry obtained in step (3) is washed and filtered by a diaphragm filter press, and a complete filter cake is formed ...

Embodiment 2

[0071] Utilize the method for the embodiment of the invention to TiCl 4 The titanium dioxide particles obtained by oxidation reaction are processed to prepare titanium dioxide slurry, the specific method is as follows:

[0072] (1) TiCl 4 The titanium dioxide particles obtained by the oxidation reaction were added to desalted water to prepare a slurry with a concentration of 600g / L. The pH value of the slurry was 3.35 and the viscosity was 70.6mPa·s;

[0073] (2) get 2L and add the aluminum sulfate solution that mass fraction is 0.2% of titanium dioxide content (its solution concentration is with Al 2 o 3 Calculated as 100g / L), the pH value of the slurry after adding is 2.36, and the viscosity is 56.3mPa·s;

[0074] (3) Add sodium hydroxide to the slurry obtained in step (2) to adjust the pH to 4.50, and the adjusted viscosity is 160.8mPa·s;

[0075] (4) The slurry obtained in step (3) is washed and filtered by a diaphragm filter press, and a complete filter cake is formed...

Embodiment 3

[0078] Utilize the method for the embodiment of the invention to TiCl 4 The titanium dioxide particles obtained by oxidation reaction are processed to prepare titanium dioxide slurry, the specific method is as follows:

[0079] (1) TiCl 4 The titanium dioxide particles obtained by the oxidation reaction were added with desalted water to prepare a slurry with a concentration of 450g / L. The pH value of the slurry was 3.37 and the viscosity was 48.2mPa·s;

[0080] (2) get 2L and add the sodium metaaluminate solution (its solution concentration is expressed as Al 2 o 3 Calculated as 100g / L), the pH value of the slurry after adding is 4.08, and the viscosity is 120.3mPa·s;

[0081] (3) adding sulfuric acid to the slurry obtained in step (2) to adjust the pH to 4.50, and the adjusted viscosity is 180.6mPa·s;

[0082] (4) The slurry obtained in step (3) is washed and filtered by a diaphragm filter press, and a complete filter cake is formed on the filter cloth without thixotropy;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com