Flame-retardant polyester

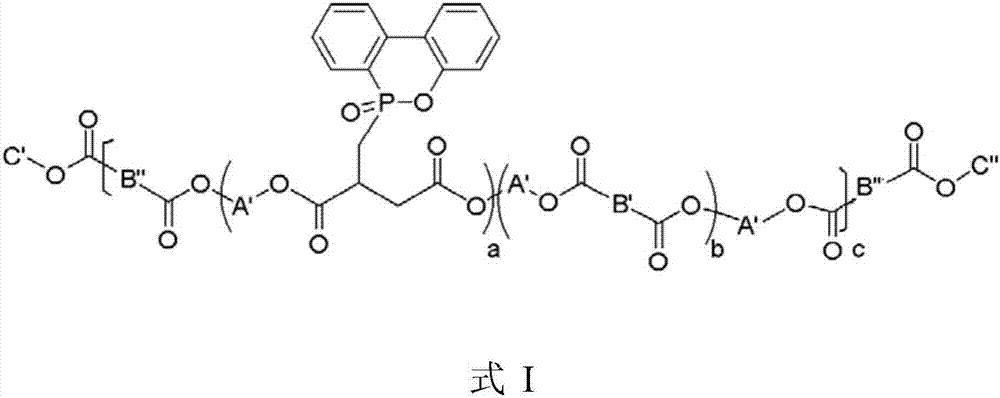

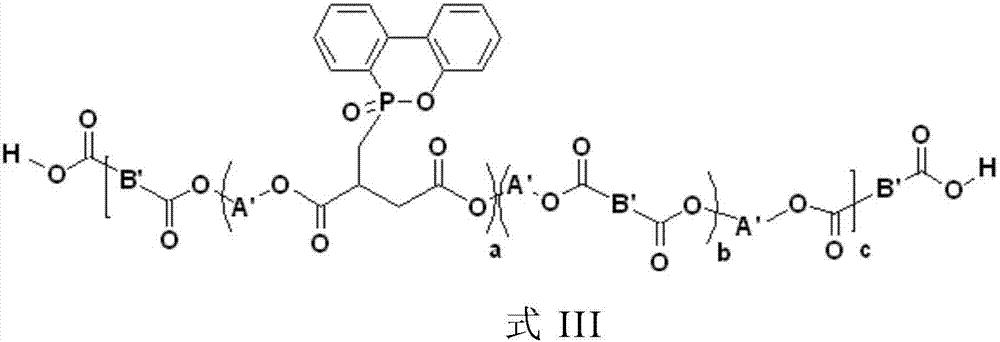

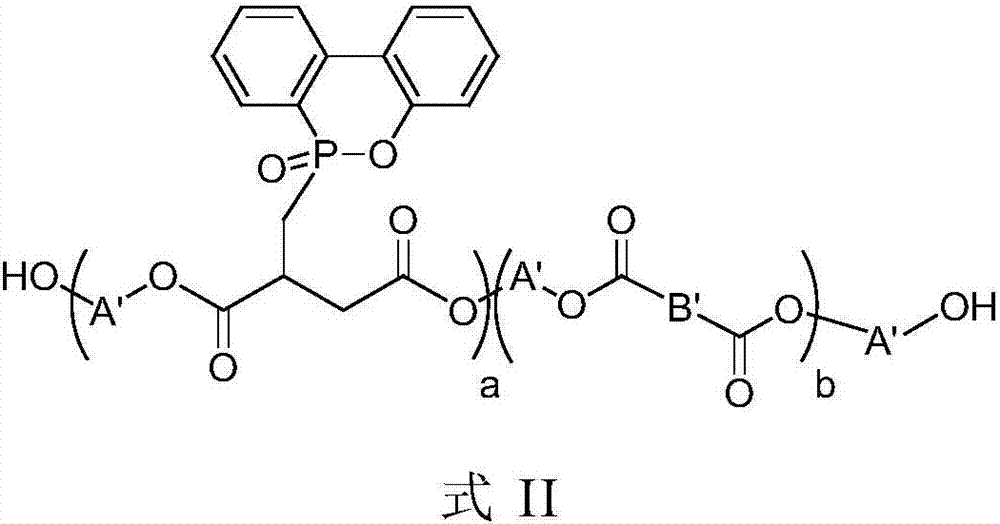

A technology of flame retardancy and polyester, which is applied in the field of phosphorus-containing unsaturated polyester, can solve compatibility problems, flame-retardant material precipitation, and limited use range, etc., and achieve the effect of high phosphorus content and stable flame-retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of the flame-retardant polyester of the present invention uses the monomer (D) as a reactant. Compared with the process using DOPO as a reactant, a flame-retardant polyester with a higher phosphorus content can be obtained, so the flame resistance is higher. good.

[0059] In the method of the present invention, the temperature range of the polymerization reaction can be determined by the selected reaction raw materials; and the time point for terminating the polymerization reaction is determined according to whether the viscosity and acid value of the obtained product reach the desired range. In terms of viscosity, the viscosity range of the obtained phosphorus-containing unsaturated polyester is preferably G-Z (tested with a GARDNER viscometer), such as G-H, I-J, K-L, M-N, O-P, Q-R, R-S, T-U, V-W, W-X or X-Y: In terms of acid value, the range of acid value of the flame retardant polyester of the present invention is not more than 40. If the acid...

Embodiment 1

[0067] Example 1: Preparation of Flame Retardant Polyester (Silicon Free) of Formula IV-1

[0068] First, 627 grams of diethylene glycol and 122 grams of dipropylene glycol were added into a 3-liter round bottom reaction flask, and stirred at 70° C. for 30 minutes. Afterwards, 276 grams of maleic anhydride (ie monomer (B2)) and 1809 grams of 10-(2,5-dicarboxypropyl)-9,10-dihydro-9-oxa-10- Put phosphaphenanthrene-10-oxide into the reaction bottle, and react at 200°C until the acid value is 65 to 75 and the viscosity is 550 to 650 (tested by high temperature viscometer, #3, 150°C, 750 rpm) . Next, add 0.165 grams of 1,4-dihydroxybenzene to the reaction flask, and drop in 323 grams of glycidyl methacrylate at 70°C, then raise the temperature to 95°C and maintain a constant temperature for 3 hours to allow the reaction Until the acid value is 25 to 30, the viscosity is 750 to 850 (tested with a high temperature viscometer, #3, 150°C, 750 rpm) and the viscosity in 35% styrene is ...

Embodiment 2

[0069] Embodiment 2: the preparation of the flame-retardant polyester composition of tool formula IV-1, IV-2 structure

[0070]First, 627 grams of diethylene glycol and 122 grams of propylene glycol were added into a 3-liter round-bottom reaction flask, and stirred at 70° C. for 30 minutes. Afterwards, 276 grams of maleic anhydride (ie monomer (B2)) and 1809 grams of 10-(2,5-dicarboxypropyl)-9,10-dihydro-9-oxa-10- Put phosphaphenanthrene-10-oxide into the reaction bottle, and react at 200°C until the acid value is 65 to 75 and the viscosity is 550 to 650 (tested by high temperature viscometer, #3, 150°C, 750 rpm) . Next, add 0.165 grams of 1,4-dihydroxybenzene to the reaction flask, and drop in 323 grams of glycidyl methacrylate at 70°C, then raise the temperature to 95°C and maintain a constant temperature for 3 hours to allow the reaction Until the acid value is 25 to 30, the viscosity is 750 to 850 (tested with a high temperature viscometer, #3, 150°C, 750 rpm) and the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com