Control system and method for container discharging and cleaning production line

A technology of a control system and a total control system, applied in cleaning methods and appliances, loading/unloading, chemical instruments and methods, etc., can solve the problems of many steps, low production efficiency, and labor-intensive, etc., and achieve rapid data exchange and improve Production efficiency and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

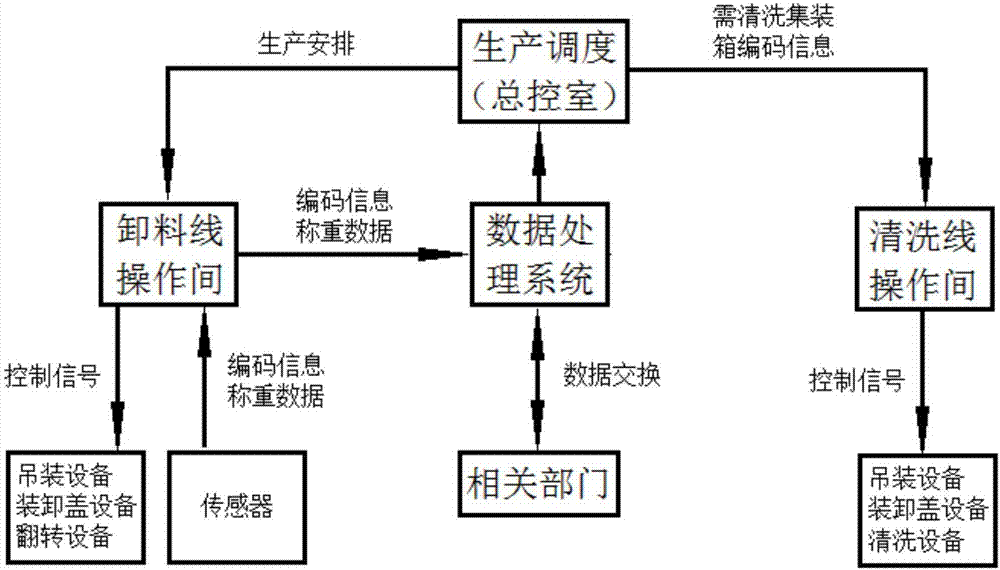

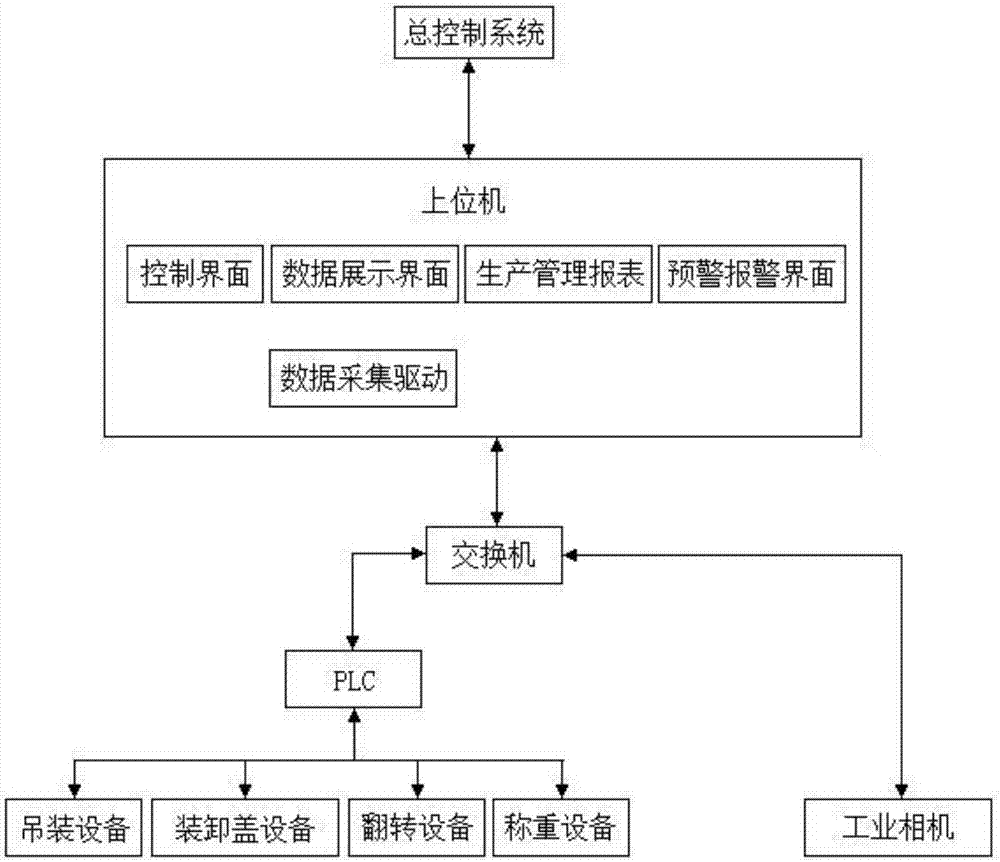

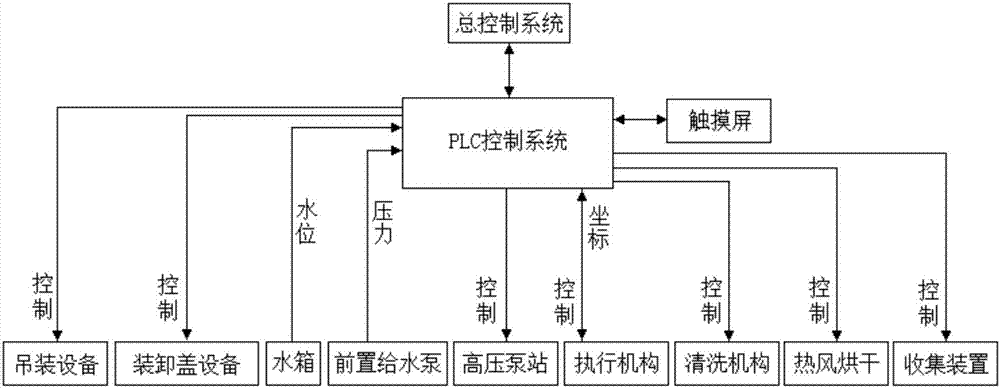

[0039] In order to solve the problem of low efficiency and high cost of manual control at the current construction site for unloading bulk granular mineral powder, it is necessary to build a reliable automatic control system for the entire unloading and cleaning workflow. The system should have the following functions:

[0040] 1. Centralized control of container hoisting equipment, loading and unloading cover equipment, turning equipment and cleaning equipment.

[0041] 2. Container identification function: number each container in advance, and realize automatic identification of the container by reading the code information on the container.

[0042] 3. Automatic weighing: record the weighing data of heavy and empty containers, and process the data to judge whether the container needs to be cleaned.

[0043] 4. Data storage, query, and transmission functions to realize data exchange with other departments.

[0044] 5. Display function: Dynamically display the operating stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com