Assembly jig

A jig and fixture technology, applied in the jig field, can solve the problems of difficult adjustment, poor moving performance, low flexibility, etc., and achieve the effect of high degree of automation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

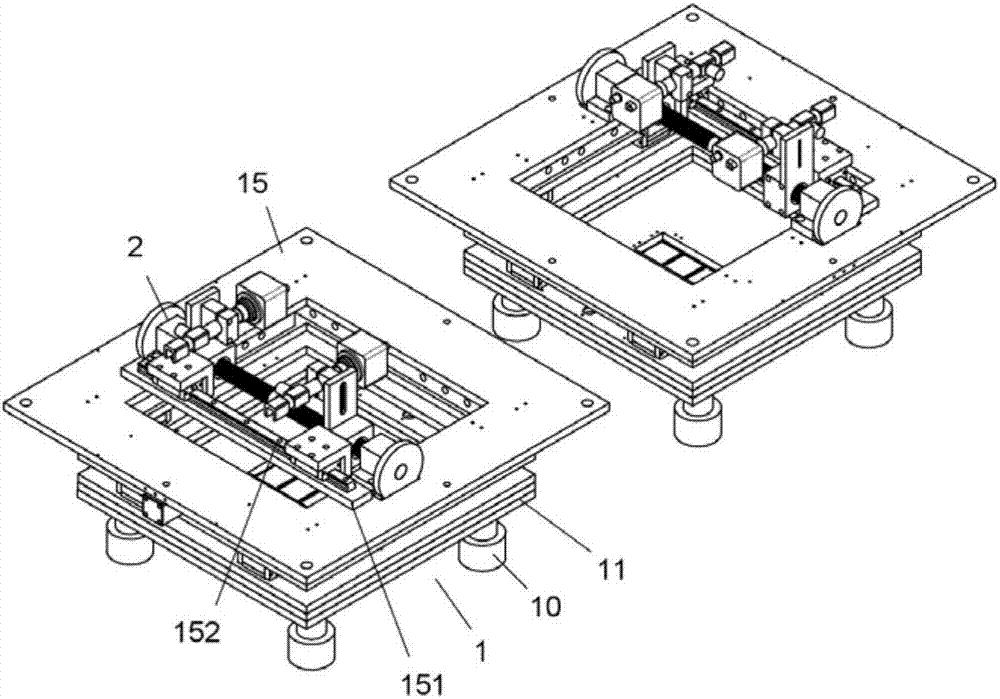

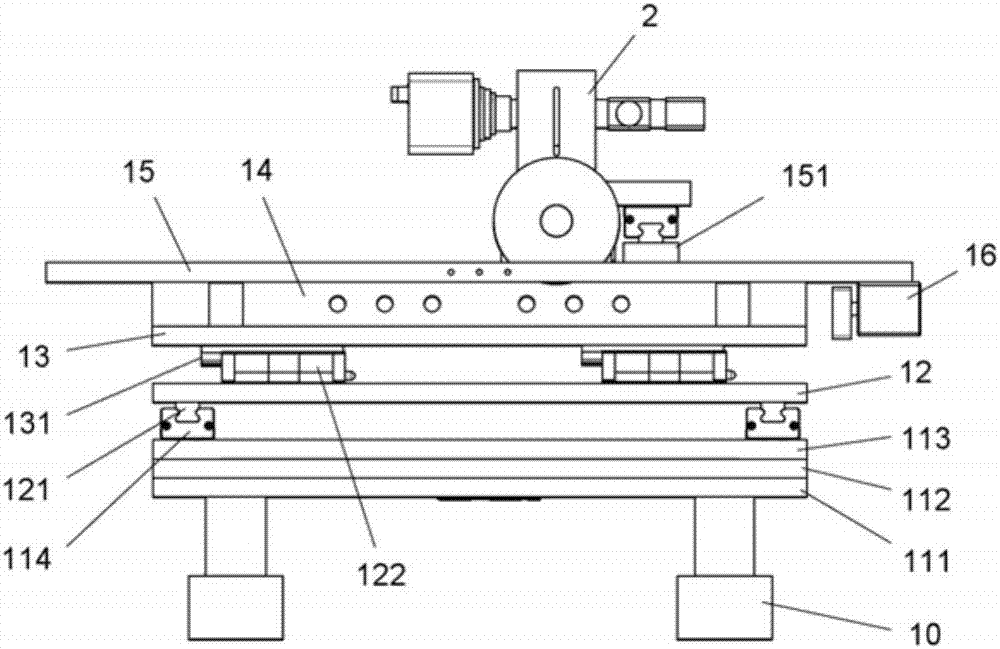

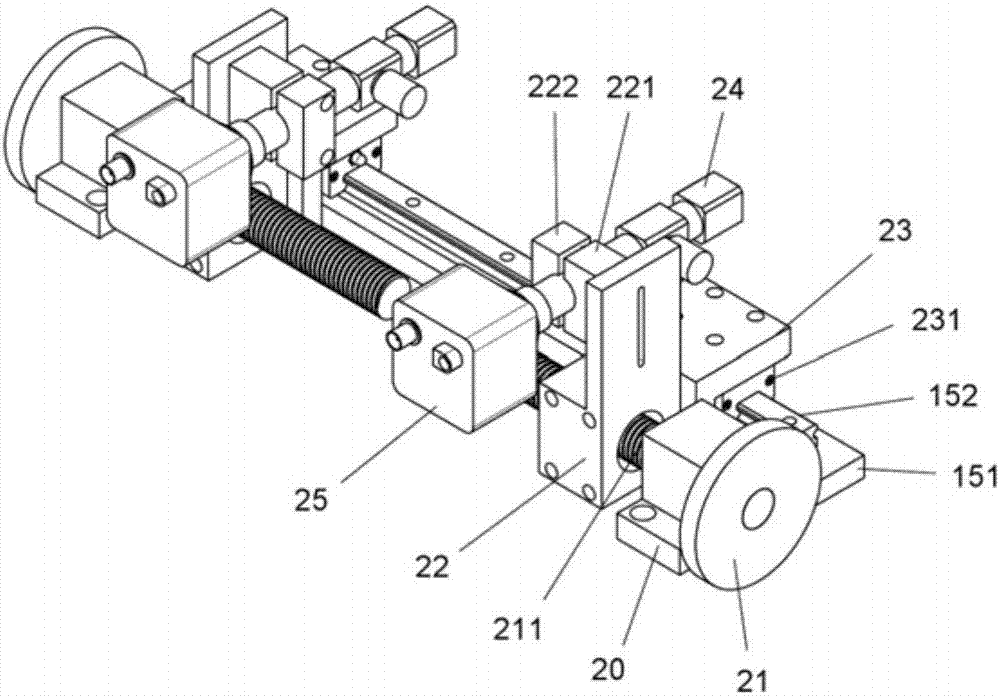

[0021] Such as Figure 1-3 As shown, an assembly jig includes two oppositely arranged fixture units 1. The two fixture units 1 have the same structure, and each includes four columns 10. A glass base 111 is fixed on the upper part of the column 10. The glass base 111 An upper base plate 112 is fixed above, and a longitudinal chute fixing plate 113 is fixed on the upper part of the upper base plate 112; 121 is fixedly connected with a lower support plate 12, and the lower support plate 12 is provided with a transverse chute 122, and a transverse slide block 131 is slidably arranged in the transverse chute 122, and a middle support plate 13 is fixed on the top of the transverse slide block 131, and the middle support plate The four uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com