Notebook computer shell polishing tool equipment based on industrial robot

A technology for industrial robots and notebook casings, applied in grinding/polishing equipment, metal processing equipment, grinding machine parts, etc., can solve problems such as low efficiency, poor polishing quality, and inability to meet the clamping of notebook casings, and achieve high efficiency High, good fit, polished surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention will be further described below in conjunction with the accompanying drawings. The examples given are only used to explain the present invention, not to limit the scope of application of the present invention.

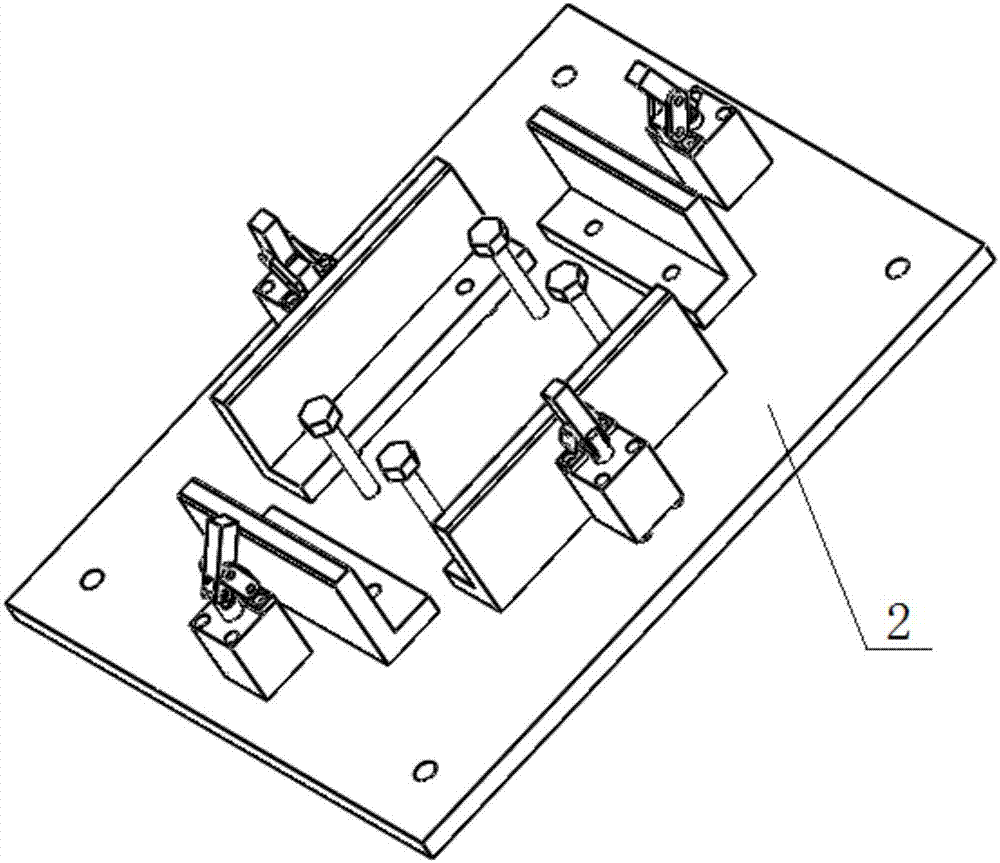

[0030] Such as Figure 1 ~ Figure 3 As shown, the notebook shell polishing tooling equipment based on the industrial robot described in the embodiment of the present invention includes at least three parts: the flexible polishing head 1, the pneumatic clamp 2 and the control unit 3, and the flexible polishing head 1 is installed on the end flange of the industrial robot 4 At the tray, the pneumatic clamp 2 is installed on a suitable workbench 6 relative to the industrial robot 4 , and the notebook case 5 is clamped on the pneumatic clamp 2 .

[0031] Such as Figure 4 As shown, the flexible polishing head 1 at least includes a connecting flange 11, two connecting plates 12, two clamping blocks 13, a compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com