Extrusion type bi-trunking milling tool absorber

A technology for milling tools and double-line grooves, which is applied to milling machine equipment, manufacturing tools, milling machine equipment details, etc., can solve problems such as practical difficulties, difficult realization, and fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

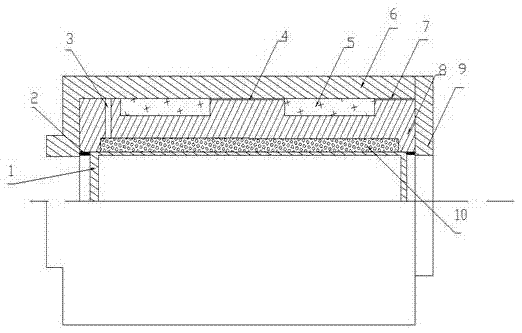

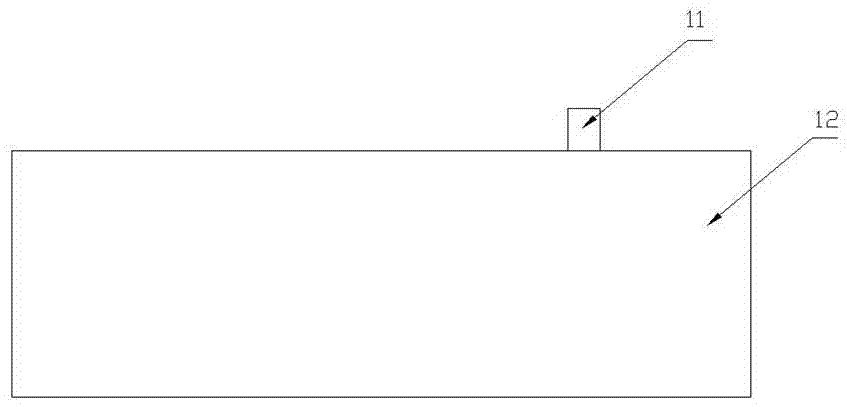

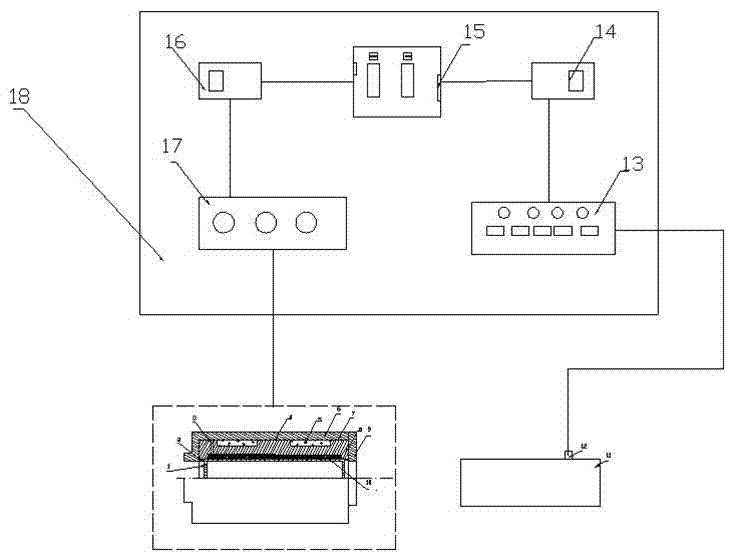

[0013] Such as figure 1 , figure 2 , image 3 As shown, the patent of the present invention includes 1 inner shaft sleeve, 2 mechanical seals, 3 liquid injection holes, 4, (7) wiring slots, 5 double coil slots, 6 clamping shaft sleeves, 8 core bodies, 9 end caps, 10 magnetorheological fluid, 11 displacement sensor, 12 milling tool, 13 signal conditioner, 14 analog-to-digital converter A / D, 15 control chip, 16 digital-to-analog converter D / A, 17 power amplifier.

[0014] Such as figure 1 As shown, the inner shaft sleeve 1 is installed into the core body 8 by a cold fitting method to form a through annular cavity. The magnetorheological fluid 10 is injected into the annular cavity through the injection hole 3 . In the two coil slots 5, 60 turns of enameled wire with a nominal diameter of 0.8 mm and a DC resistance of 34.8 ohms per kilometer are respectively wound to form an excitation coil. The lead-out wires of the excitation coil lead out of the shock absorber through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com