Automatic secondary degassing fixed-length mechanism of ultrathin heat pipes

一种超薄热管、自动的技术,应用在间接换热器、照明和加热设备等方向,能够解决薄壁热管管身易出现局部凹陷、不适宜加工薄壁热管、不良品率增加等问题,达到生产稳定高效、合格率提高、企业的经济效益提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

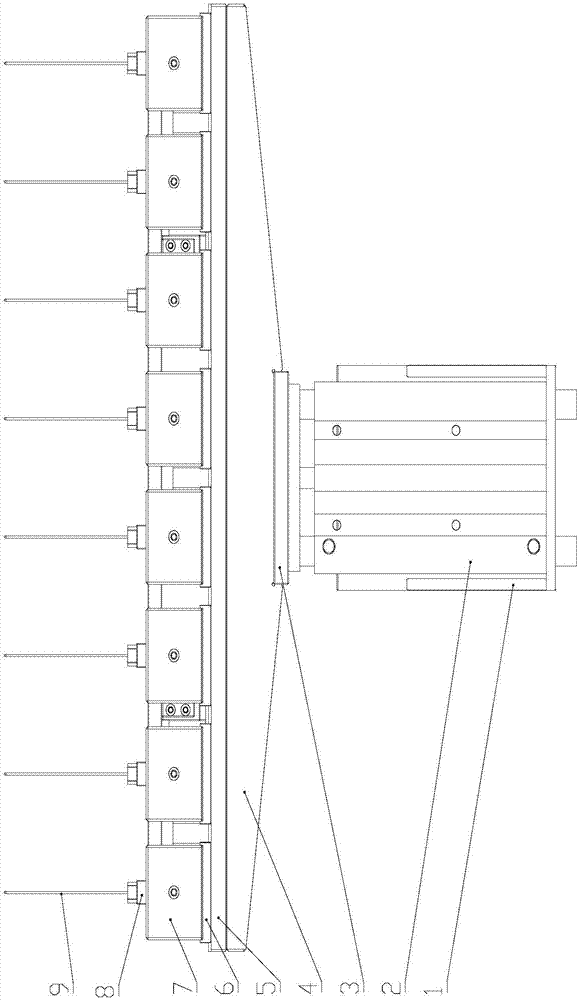

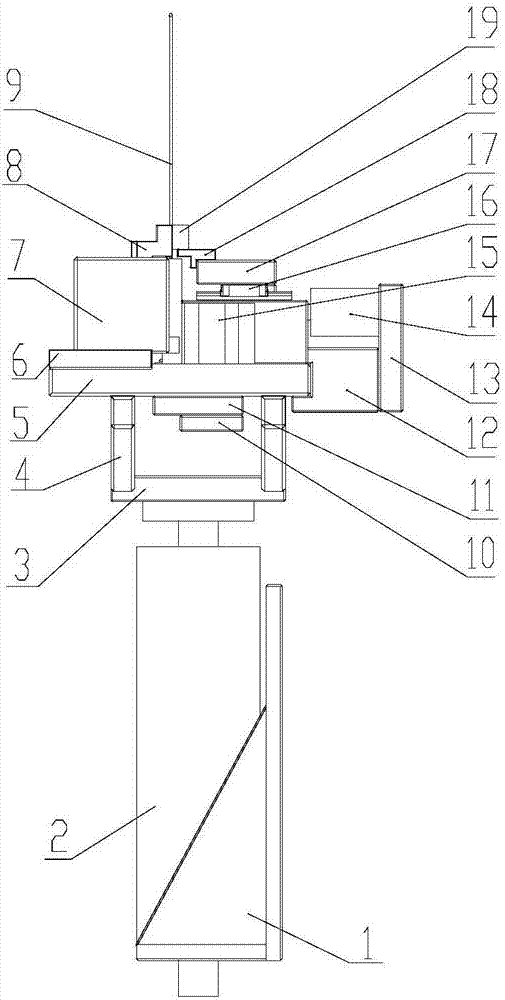

[0024] An ultra-thin heat pipe automatic secondary degassing and length fixing mechanism, such as figure 2 and image 3 As shown, it includes automatic lifting device A, automatic clamping device B, length positioning extension device C and PLC installed on the length adjustment slide table; automatic lifting device A consists of lifting cylinder base 1, lifting cylinder 2, and lifting cylinder connecting plate 3. The support plate 4 and the reference base plate 5 are composed of; the lift cylinder base 1 installed on the length adjustment slide table is locked with the inherent lift cylinder 2, and the piston push plate of the lift cylinder 2 passes through the lift cylinder connecting plate 3, and two supports are fixed vertically The plate 4 and the reference base plate 5 are installed and fixed above the two vertically installed support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com