Engine upper cover

An engine and body technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of inability to ensure the correct installation angle of the camshaft, increase structural complexity, and complex cylinder head structure, so as to reduce the weight of the upper cover. Compact structure and the effect of reducing pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

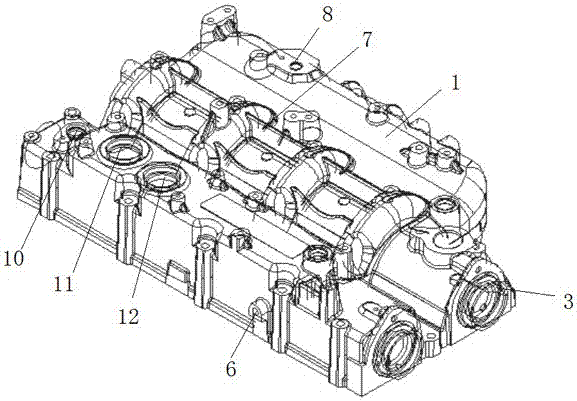

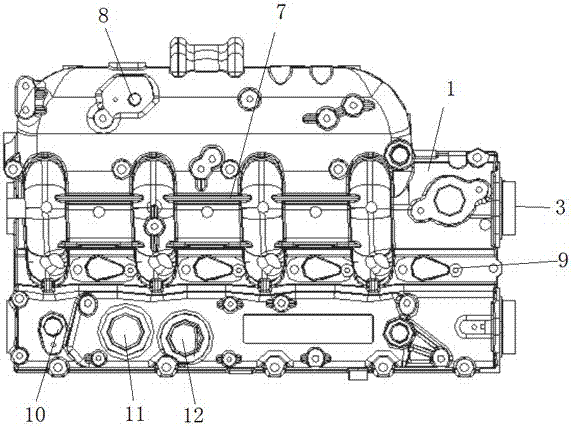

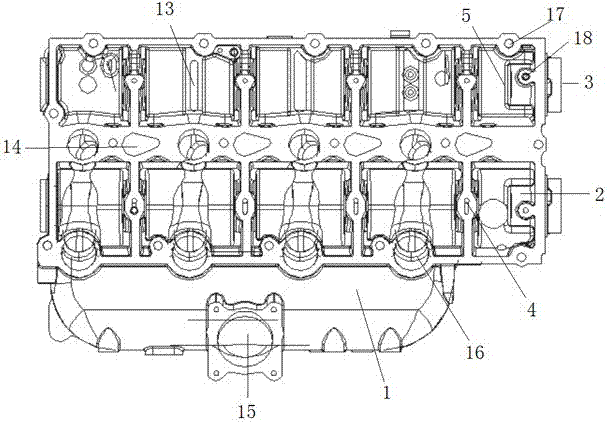

[0034] see Figure 1-Figure 9 , a kind of engine upper cover that the present invention relates to, it comprises upper cover main body 1, and upper cover main body 1 is provided with two transverse camshaft extension bosses 2, and the side of camshaft extension boss 2 close to pulley chamber is arranged There is a camshaft extension boss 3, and the camshaft extension boss 2 protrudes out of the upper cover body 1. When in use, the camshaft extension boss 3 is sealed and installed with the contact part of the pulley chamber, so as to effectively prevent the inflow of liquid, so as to achieve Safe and reliable purpose.

[0035] The bottom surface of the upper cover body 1 is provided with a plurality of oil supply holes 4 corresponding to the two camshaft extension bosses 2. As a preference, each camshaft extension boss 2 corresponds to four oil supply holes evenly arranged. 4. The chute on the surface of the oil supply hole 4 communicates with the cylinder block, so that when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com