Bidirectional water stop side check seal

A technology of water stop and water stop board, which is applied in water conservancy projects, sea area projects, coastline protection, etc. It can solve the problems of no two-way water stop effect, difficulty in ensuring leakage rate, strict error control, etc., and achieve the effect of two-way water sealing , Guaranteed service life, maintenance-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

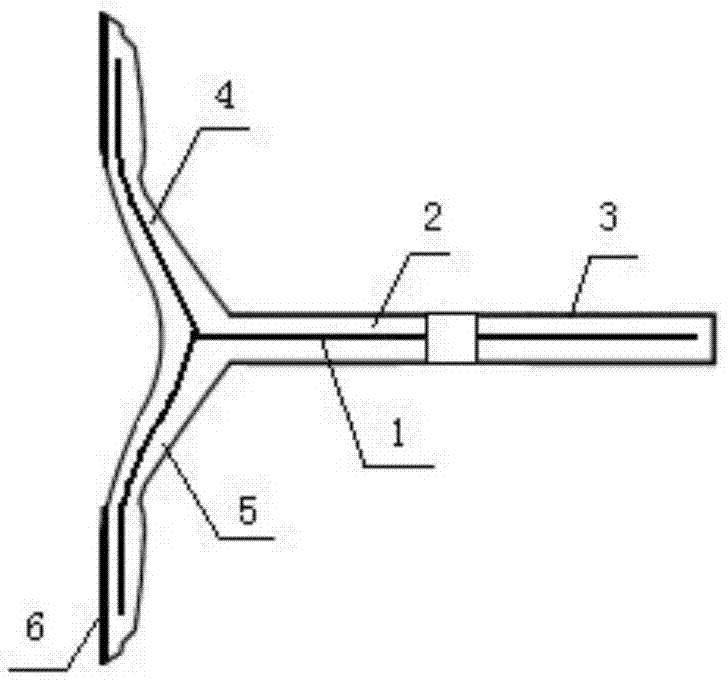

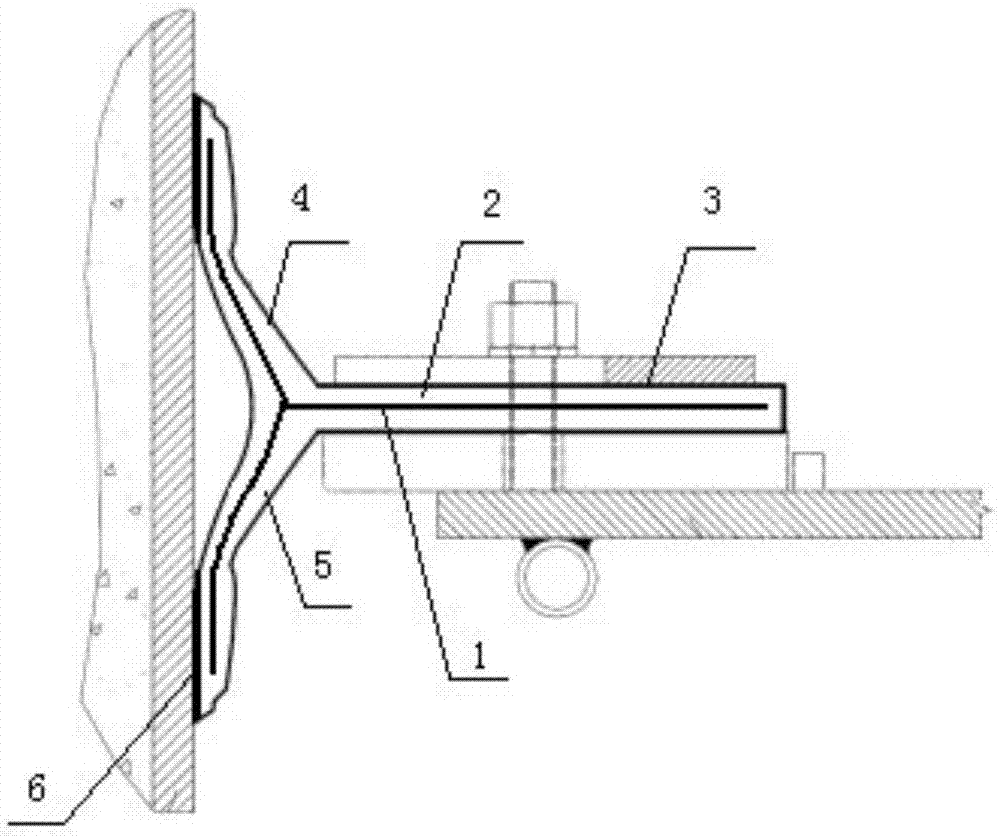

[0009] Example: see attached figure 1 , 2 , two-way water-stop side seal, with a "Y"-shaped side seal body, the "Y"-shaped side seal body is provided with a fixed plate part 3 in contact with the steel gate, and the fixed plate part is reserved There are fixed holes separated by a certain standard distance, and the "Y" type side seal body is provided with an inner water-stop plate 4 and an outer water-stop plate 5, and the inner water-stop plate and the outer water-stop plate are at the top A self-sealing rubber soft layer 6 is provided on the outer surface of the body, and a steel inner skeleton 1 is arranged inside the "Y" type side seal body, and a rubber sealing layer 2 is wrapped outside the steel inner skeleton. The outside of the inner frame is bonded together with the rubber sealing layer by Lechner adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com