Environment-friendly plant oil-based ink used for offset printing

A vegetable oil-based, environmentally friendly technology, applied in the field of ink printing, can solve the problem of irritating odor of ink, and achieve the effects of good ink adhesion, uniform ink color, and good friction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

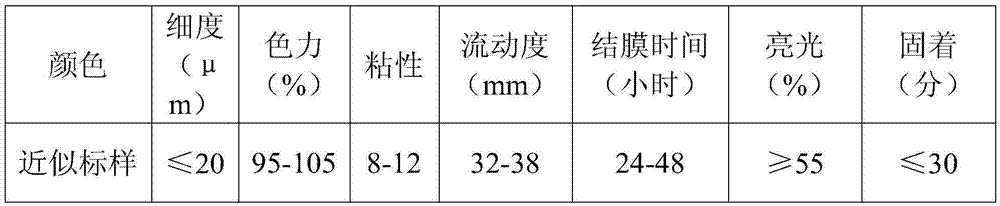

Examples

Embodiment 1

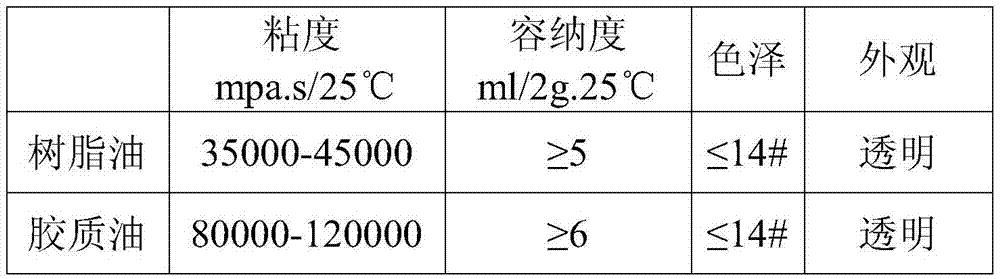

[0066] In the present invention, the various material components and weight percentages of the colloidal oil are: TN-21 resin 40, soybean oil 59, liquid aluminum 1.

Embodiment 2

[0068] In the present invention, the components and weight percentages of the resin oil are: TN-20 resin 40, soybean oil 60.

Embodiment 3

[0070] Each material component and weight percentage of the present invention are: colloidal oil 30, resin oil 39, soybean oil solvent 14.8, 12-6 benzidine yellow 14, wax powder 1, 4# anti-water additive 0.4, 4% cobalt 0.2 , 3% Manganese 0.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com