Method for co-processing arsenic-containing sludge and lake sediment

A co-processing and bottom sludge technology, which is applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of secondary pollution of arsenic-containing sludge environment, solve the solidification problem, realize Effect of secondary utilization and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The method for the co-processing of arsenic-containing sludge in the lake sediment, the specific steps are as follows:

[0019] (1) Pretreatment: First, control the moisture content of the arsenic-containing sludge (composition shown in Table 1) obtained after the arsenic-acid-containing wastewater lime-iron-salt treatment to 2 and Al 2 o 3 For lake sediments with a total content >50% (the composition is shown in Table 2), control the water content >50%;

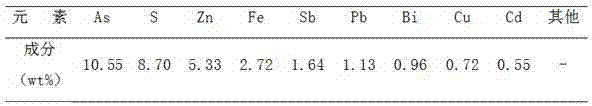

[0020] Table 1 Composition of arsenic-containing sludge

[0021]

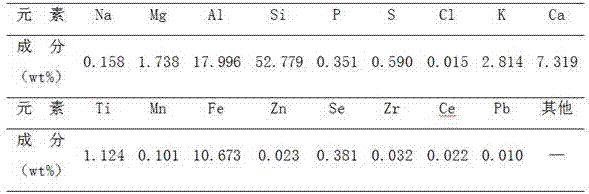

[0022] Table 2 The composition of lake sediment

[0023]

[0024] (2) Synergistic treatment: First, the arsenic-containing sludge, lake sediment, cement, lime, activator and admixture obtained through the pretreatment of step (1) are ball milled according to the mass ratio of 49:30:8:8:3:2 Mix evenly to obtain a dry basis, and the sum of the content percentages of the above components is equal to 100%; wherein the activator is water glass, and...

Embodiment 2

[0028] The method for the co-processing of arsenic-containing sludge in the lake sediment, the specific steps are as follows:

[0029] (1) Pretreatment: First, control the moisture content of the arsenic-containing sludge (composition shown in Table 1) obtained after the arsenic-acid-containing wastewater lime-iron-salt treatment to 2 and Al 2 o 3 For lake sediments with a total content >50% (the composition is shown in Table 2), control the water content >50%;

[0030] (2) Synergistic treatment: First, the arsenic-containing sludge, lake sediment, cement, lime, activator and admixture obtained through the pretreatment of step (1) are ball milled according to the mass ratio of 40:35:9:10:4:2 Mix evenly to obtain a dry basis, and the sum of the content percentages of the above components is equal to 100%; wherein the activator is water glass, and the admixture is silica fume;

[0031] (3) Curing: Add 8% water to the dry base obtained in step (2) and stir evenly, and then pres...

Embodiment 3

[0034] The method for the co-processing of arsenic-containing sludge in the lake sediment, the specific steps are as follows:

[0035] (1) Pretreatment: First, control the moisture content of the arsenic-containing sludge (composition shown in Table 1) obtained after the arsenic-acid-containing wastewater lime-iron-salt treatment to 2 and Al 2 o 3 For lake sediments with a total content >50% (the composition is shown in Table 2), control the water content >50%;

[0036] (2) Synergistic treatment: First, the arsenic-containing sludge, lake sediment, cement, lime, activator and admixture obtained through the pretreatment of step (1) are ball milled according to the mass ratio of 60:20:5:12:2:1 Mix evenly to obtain a dry basis, and the sum of the content percentages of the above components is equal to 100%; wherein the activator is water glass, and the admixture is silica fume;

[0037] (3) Curing: Add 16% water to the dry base obtained in step (2) and stir evenly, and then pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com