Overturn clearing-up type tartarian buckwheat conveying mechanism

A technology of tartary buckwheat and transport box, which is applied in the field of flipping and cleaning tartary buckwheat transport mechanism, which can solve the problems of iron filings residue and influence on product purity, and achieve the effects of preventing jamming, improving product purity and quality, and good synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

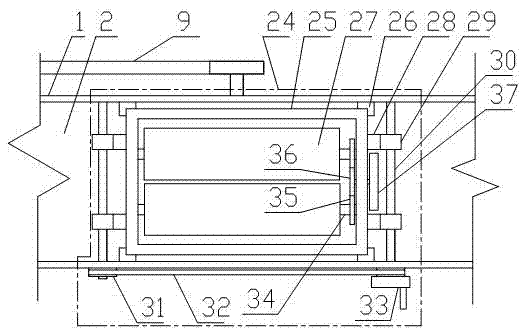

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0012] Example. A kind of turning and cleaning type tartary buckwheat transportation mechanism, constituted as Figure 1-3 As shown, the transport box 1 is included, the transport box 1 is provided with a transport plate 2, the two ends of the transport plate 2 are respectively provided with a material inlet 3 and a discharge port 4, and the transport box 1 is connected to the base frame 6 through the elastic arm 5; Described pedestal 6 is provided with two support bases 7, is provided with transmission shaft 8 between two support bases 7, and one end of transmission shaft 8 is connected with driving motor 10 through transmission belt 9, and the transmission shaft 8 between two support bases 7 It is also eccentrically connected with the vibrating sleeve 12 via the bearing 11, and the vibrating slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com