Graphite phase carbide nitride nanosheet/ZiF-67 lamellar structure composite material

A composite material, lamellar structure technology, applied in chemical/physical processes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low quantum dot efficiency, small specific surface area, and few active sites, etc. Achieve excellent photocatalytic performance, large specific surface area, and many sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Spread 2 g of melamine powder on the bottom of a 50 mL crucible, close the lid tightly, transfer to a muffle furnace, raise the temperature to 550 °C at a rate of 2.3 °C / min and keep it for 4 h, then increase the temperature at a rate of 2.3 °C / min Cool down to room temperature to get pale yellow g-C 3 N 4 powder;

[0028] 2) Take 0.3 g of g-C prepared above 3 N 4 powder, add 200 mL deionized water, 150 W ultrasonic stripping for 6 h, centrifuge the solution at 3000 rpm for 5 min, remove the unexfoliated solids in the lower layer, and freeze-dry the obtained supernatant to obtain g-C 3 N 4 Nanosheet solids.

Embodiment 2

[0030] 1) the obtained g-C of embodiment 1 3 N 4 The solid nanosheets were dissolved in a mixed solvent of methanol-ethanol (v:v=1:1), and dispersed by ultrasound to obtain g-C with a concentration of 1mg / mL 3 N 4 nanosheet dispersion;

[0031] 2) Add 150 mg Co(NO 3 ) 2 ·6H 2 O dissolved in 20 mL g-C 3 N 4 nanosheet dispersion to obtain solution A; take a 100 mL Erlenmeyer flask, and inject solution A into the bottom of the glass bottle;

[0032] 3) Dissolve 160 mg of 2-methylimidazole in 20 mL of methanol-ethanol mixed solvent with a volume ratio of 1:1 to obtain solution B;

[0033] 4) Rapidly inject solution B into solution A and stir vigorously for 30 s, then let it stand for 24 h;

[0034] 5) After the reaction is completed, the obtained purple powder is repeatedly washed with methanol and ethanol for 3-4 times, centrifuged at 8000 rpm for 5 minutes, and dried in vacuum at 100°C overnight to obtain g-C 3 N 4 Nanosheet / ZiF-67 composites.

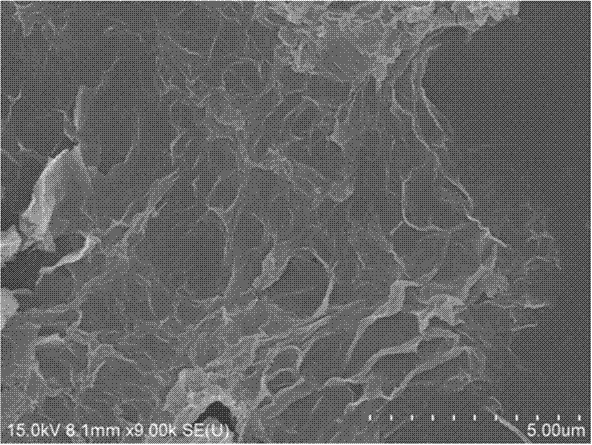

[0035] figure 1 , 2...

Embodiment 3

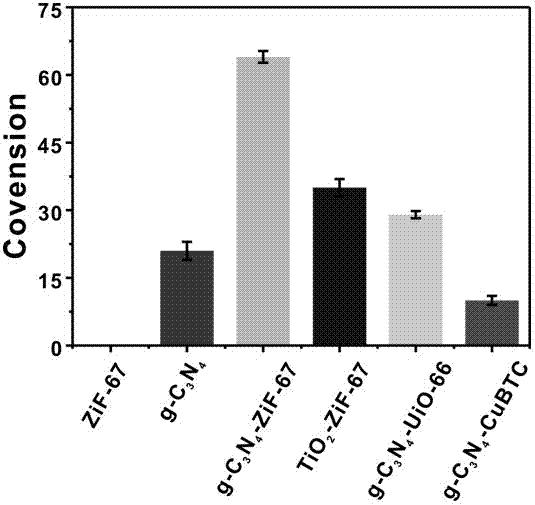

[0036] Example 3 Photocatalytic carbon dioxide reduction experiment

[0037] At room temperature, 1 atm CO 2 Under the condition of , add 150 mg g-C in 80 mL reaction kettle 3 N 4The nanosheet / ZiF-67 composite was used as the catalyst, and 10 mL of deionized water was added as the reaction raw material, and the reaction was performed under magnetic stirring for 1 h. A 500 W Xe light source was used as a light source during the reaction, and a filter was used to filter out light below 420 nm. Final gaseous products were detected using an Agilent 7820A gas chromatograph. Simultaneously with g-C 3 N 4 Nanosheets, commercially available ZiF-67 and TiO 2 / ZiF-67 composite material, g-C 3 N 4 / UiO-66 (Zr) composite material, g-C 3 N 4 / CuBTC composites for comparison. see results image 3 .

[0038] Depend on image 3 Visible, with g-C 3 N 4 Compared with nanosheets, commercially available ZiF-67 and other composite materials, g-C prepared by the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com