Preparation method of lithium iron phosphate cathode material

A lithium iron phosphate, cathode material technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of uncontrollable distribution, reduce the specific capacity of the electrode and the tap density of the material, and improve the capacity and cycle. performance, improved electrical conductivity, and the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

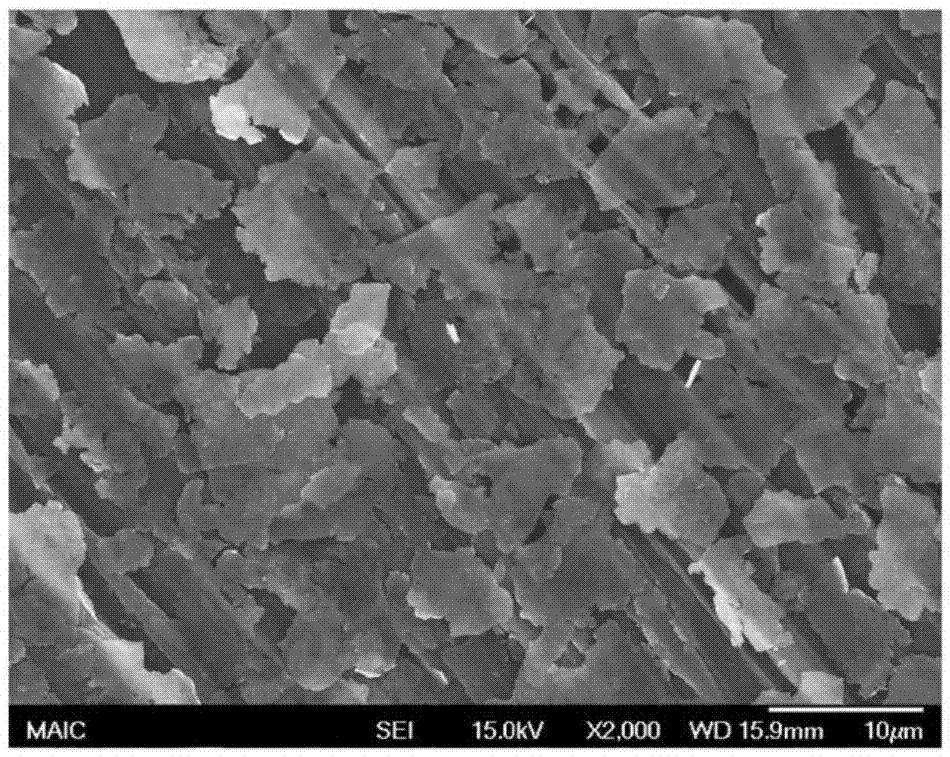

[0020] A method for preparing a lithium iron phosphate cathode material, comprising the steps of:

[0021] Step 1, weigh lithium carbonate, ammonium dihydrogen phosphate, ferrous oxalate respectively according to the ratio of stoichiometric ratio 1:1:1, add dehydrated alcohol (dehydrated alcohol and lithium carbonate, ammonium dihydrogen phosphate, ferrous oxalate raw material The volume ratio is 1.5:1~2.2:1), after mixing evenly, perform ball milling at 350~450rpm for 6~10 hours, and then vacuum dry at 60~100°C for 10~20 hours to obtain lithium iron phosphate precursor powder;

[0022] Step 2. Keep the lithium iron phosphate precursor prepared in step 1 in a tube furnace protected by a pure nitrogen atmosphere at 350-450°C for 4-6 hours, continue to heat up to 600-800°C for 6-10 hours, and then cool naturally to Obtain lithium iron phosphate cathode material at room temperature;

[0023] Step 3. Weigh 1wt.% to 3wt.% copper flakes of the lithium iron phosphate mass obtained i...

Embodiment 1

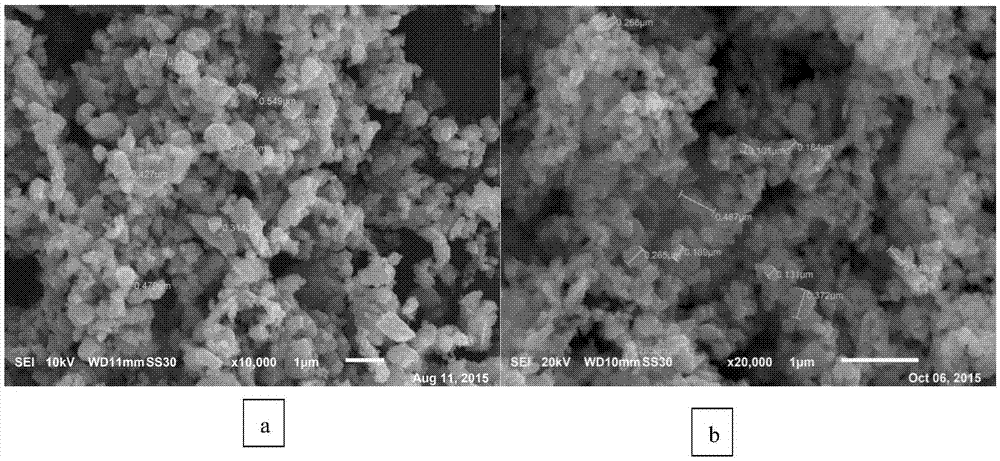

[0025] Step 1. Weigh 0.05mol of lithium carbonate, ammonium dihydrogen phosphate, and ferrous oxalate, add 30mL of absolute ethanol and mix evenly, then ball mill at 400rpm / min for 6h, and dry in a vacuum oven at 80°C for 12h after ball milling to obtain lithium iron phosphate Precursor powder;

[0026] Step 2. Place the lithium iron phosphate precursor powder in a tube furnace protected by a pure nitrogen atmosphere, raise the temperature to 350°C at a heating rate of 5°C / min, keep it for 4 hours, and then raise the temperature to 650°C at a rate of 5°C / min. Keeping the temperature for 10 hours, and cooling naturally to room temperature to obtain the lithium iron phosphate positive electrode material.

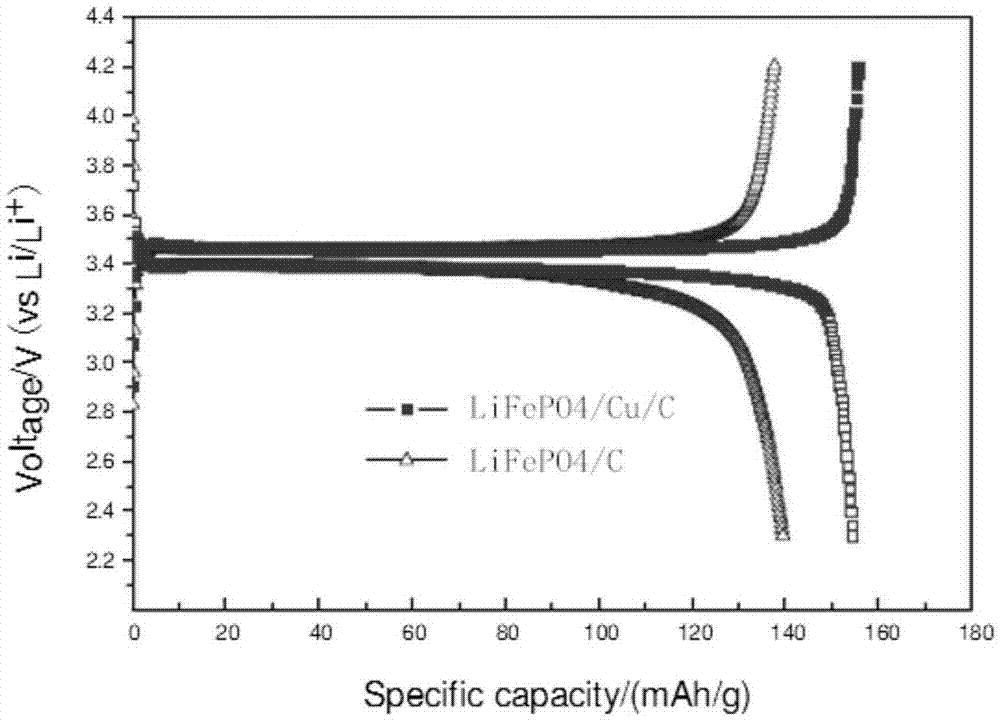

[0027] Step 3. Weigh 0.11g of copper flakes and 1.1g of sucrose and add them to the prepared lithium iron phosphate cathode material, ball mill for 1 hour to mix the materials evenly; then wash with absolute ethanol for 3 times and centrifuge, and dry at 50°C for 10 hours; Dr...

Embodiment 2

[0030] Step 1. Weigh 0.05mol of lithium carbonate, ammonium dihydrogen phosphate, and ferrous oxalate, add 30mL of absolute ethanol and mix evenly, then ball mill at 400rpm / min for 8h, and dry in a vacuum oven at 80°C for 12h after ball milling to obtain lithium iron phosphate Precursor powder;

[0031] Step 2. Place the lithium iron phosphate precursor powder in a tube furnace protected by a pure nitrogen atmosphere, raise the temperature to 350°C at a heating rate of 5°C / min, keep it for 4 hours, and then raise the temperature to 650°C at a rate of 5°C / min. Keeping the temperature for 10 hours, and cooling naturally to room temperature to obtain the lithium iron phosphate positive electrode material.

[0032] Step 3. Weigh 0.22g of copper flakes and 1.1g of sucrose and add them to the prepared lithium iron phosphate cathode material, ball mill for 2 hours to mix the materials evenly; then wash with absolute ethanol for 3 times and centrifuge, and dry at 50°C for 10 hours; D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com